Каталог Sumitomo фрезы со сменными пластинами - страница 94

Навигация

- H001

- H002

- H003

- H004

- H005

- H006

- H007

- H008

- H009

- H010

- H011

- H012

- H013

- H014

- H015

- H016

- H017

- H018

- H019

- H020

- H021

- H022

- H023

- H024

- H025

- H026

- H027

- H028

- H029

- H030

- H031

- H032

- H033

- H034

- H035

- H036

- H037

- H038

- H039

- H040

- H041

- H042

- H043

- H044

- H045

- H046

- H047

- H048

- H049

- H050

- H051

- H052

- H053

- H054

- H055

- H056

- H057

- H058

- H059

- H060

- H061

- H062

- H063

- H064

- H065

- H066

- H067

- H068

- H069

- H070

- H071

- H072

- H073

- H074

- H075

- H076

- H077

- H078

- H079

- H080

- H081

- H082

- H083

- H084

- H085

- H086

- H087

- H088

- H089

- H090

- H091

- H092

- H093

- H094

- H095

- H096

- H097

- H098

- H099

- H100

- H101

- H102

- H103

- H104

- H105

- H106

- H107

- H108

- H109

- H110

- H111

- H112

- H113

- H114

- H115

- H116

- H117

- H118

- H119

- H120

- H121

- H122

- H123

- H124

- H125

- H126

- H127

- H128

- H129

- H130

- H131

- H132

- H133

- H134

- H135

- H136

- H137

- H138

- H139

- H140

- H141

- H142

- H143

- H144

- H145

- H146

- H147

- H148

- H149

- H150

- H151

- H152

- H153

- H154

- H155

- H156

- H157

- H158

- H159

- H160

- H161

- H162

- H163

- H164

- H165

- H166

- H167

- H168

- H169

- H170

- H171

- H172

- H173

- H174

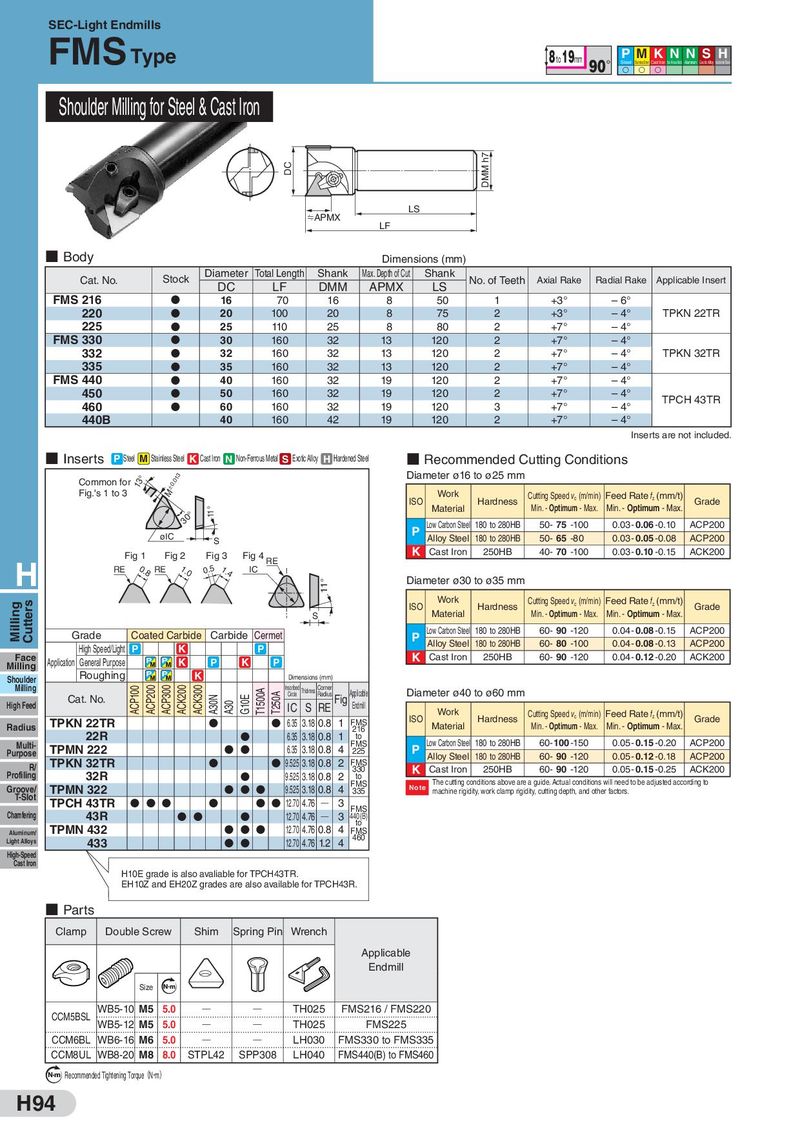

SEC-Light Endmills FMS Type 8 to 19mm P MKN N SH 90°Steel Stainless Steel Cast Iron Non-Ferrous Metal Aluminum Exotic Alloy Hardened Steel S S S Shoulder Milling for Steel & Cast Iron DC DMM h7 LS ≒APMX LF ■ Body Dimensions (mm) Cat. No. Stock Diameter Total Length Shank Max. Depth of Cut Shank No. of Teeth Axial Rake Radial Rake Applicable Insert DC LF DMM APMX LS FMS 216 D 16 70 16 8 50 1 +3° – 6° 220 D 20 100 20 8 75 2 +3° – 4° TPKN 22TR 225 D 25 110 25 8 80 2 +7° – 4° FMS 330 D 30 160 32 13 120 2 +7° – 4° 332 D 32 160 32 13 120 2 +7° – 4° TPKN 32TR 335 D 35 160 32 13 120 2 +7° – 4° FMS 440 D 40 160 32 19 120 2 +7° – 4° 450 D 50 160 32 19 120 2 +7° – 4° TPCH 43TR 460 D 60 160 32 19 120 3 +7° – 4° 440B 40 160 42 19 120 2 +7° – 4° Inserts are not included. ■ Inserts P Steel M Stainless Steel K Cast Iron N Non-Ferrous Metal S Exotic Alloy H Hardened Steel ■ Recommended Cutting Conditions Common for 13° M ±0.013 Diameter ø16 to ø25 mm Fig.'s 1 to 3 ISO Work Hardness Cutting Speed vc (m/min) Feed Rate fz (mm/t) Grade 11° Material Min. - Optimum - Max. Min. - Optimum - Max. 30° Low Carbon Steel 180 to 280HB 50- 75 -100 0.03- 0.06 -0.10 ACP200 øIC S P Alloy Steel 180 to 280HB 50- 65 -80 0.03- 0.05 -0.08 ACP200 Fig 1 Fig 2 Fig 3 Fig 4 RE K Cast Iron 250HB 40- 70 -100 0.03- 0.10 -0.15 ACK200 H RE 0.8 RE 1.0 0.5 1.4 IC 11° Diameter ø30 to ø35 mm Milling Cutters ISO Work Hardness Cutting Speed vc (m/min) Feed Rate fz (mm/t) Grade S Material Min. - Optimum - Max. Min. - Optimum - Max. Grade Coated Carbide Carbide Cermet P Low Carbon Steel 180 to 280HB 60- 90 -120 0.04- 0.08 -0.15 ACP200 High Speed/Light P K P Alloy Steel 180 to 280HB 60- 80 -100 0.04- 0.08 -0.13 ACP200 Face Application General Purpose K P K P K Cast Iron 250HB 60- 90 -120 0.04- 0.12 -0.20 ACK200 Milling Shoulder Roughing K Dimensions (mm) Milling ACP100 ACP200 ACP300 ACK200 ACK300 T1500A Inscribed Thickness Corner Applicable Diameter ø40 to ø60 mm Cat. No. A30N G10E T250A Circle Radius Fig High Feed A30 IC S RE Endmil Work Cutting Speed vc (m/min) Feed Rate fz (mm/t) Radius TPKN 22TR D D 6.35 3.18 0.8 1 FMS ISO Material Hardness Min. - Optimum - Max. Min. - Optimum - Max. Grade 22R 6.35 3.18 0.8 1 216 D to FMS Low Carbon Steel 180 to 280HB 60- 100 -150 0.05- 0.15 -0.20 ACP200 Multi- TPMN 222 D D 6.35 3.18 0.8 4 225 P Purpose Alloy Steel 180 to 280HB 60- 90 -120 0.05- 0.12 -0.18 ACP200 TPKN 32TR D D 9.525 3.18 0.8 2 FMS R/ 330 K Cast Iron 250HB 60- 90 -120 0.05- 0.15 -0.25 ACK200 Profiling 32R 9.525 3.18 0.8 2 to D FMS The cutting conditions above are a guide. Actual conditions will need to be adjusted according to Groove/ TPMN 322 D D D 9.525 3.18 0.8 4 335 Note machine rigidity, work clamp rigidity, cutting depth, and other factors. T-Slot TPCH 43TR D D D D D D 12.70 4.76 Q 3 Chamfering 43R 12.70 4.76 3 FMS D D D Q 440(B) to TPMN 432 D D D 12.70 4.76 0.8 4 FMS Aluminum/ 460 Light Alloys 433 D D 12.70 4.76 1.2 4 High-Speed Cast Iron H10E grade is also avaliable for TPCH43TR. EH10Z and EH20Z grades are also available for TPCH43R. ■ Parts Clamp Double Screw Shim Spring Pin Wrench Applicable Endmill Size Nm CCM5BSL WB5-10 M5 5.0 Q Q TH025 FMS216 / FMS220 WB5-12 M5 5.0 Q Q TH025 FMS225 CCM6BL WB6-16 M6 5.0 Q Q LH030 FMS330 to FMS335 CCM8UL WB8-20 M8 8.0 STPL42 SPP308 LH040 FMS440(B) to FMS460 N m Recommended Tightening Torque(N・m) H94

Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo модульные системы для револьверных головок токарных станков

Каталог Sumitomo модульные системы для револьверных головок токарных станков Каталог Sumitomo токарные резцы (державки) для внутреннего точения

Каталог Sumitomo токарные резцы (державки) для внутреннего точения Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019 Каталог Sumitomo монолитные фрезы

Каталог Sumitomo монолитные фрезы