Каталог Sumitomo фрезы со сменными пластинами - страница 12

Навигация

- H001

- H002

- H003

- H004

- H005

- H006

- H007

- H008

- H009

- H010

- H011

- H012

- H013

- H014

- H015

- H016

- H017

- H018

- H019

- H020

- H021

- H022

- H023

- H024

- H025

- H026

- H027

- H028

- H029

- H030

- H031

- H032

- H033

- H034

- H035

- H036

- H037

- H038

- H039

- H040

- H041

- H042

- H043

- H044

- H045

- H046

- H047

- H048

- H049

- H050

- H051

- H052

- H053

- H054

- H055

- H056

- H057

- H058

- H059

- H060

- H061

- H062

- H063

- H064

- H065

- H066

- H067

- H068

- H069

- H070

- H071

- H072

- H073

- H074

- H075

- H076

- H077

- H078

- H079

- H080

- H081

- H082

- H083

- H084

- H085

- H086

- H087

- H088

- H089

- H090

- H091

- H092

- H093

- H094

- H095

- H096

- H097

- H098

- H099

- H100

- H101

- H102

- H103

- H104

- H105

- H106

- H107

- H108

- H109

- H110

- H111

- H112

- H113

- H114

- H115

- H116

- H117

- H118

- H119

- H120

- H121

- H122

- H123

- H124

- H125

- H126

- H127

- H128

- H129

- H130

- H131

- H132

- H133

- H134

- H135

- H136

- H137

- H138

- H139

- H140

- H141

- H142

- H143

- H144

- H145

- H146

- H147

- H148

- H149

- H150

- H151

- H152

- H153

- H154

- H155

- H156

- H157

- H158

- H159

- H160

- H161

- H162

- H163

- H164

- H165

- H166

- H167

- H168

- H169

- H170

- H171

- H172

- H173

- H174

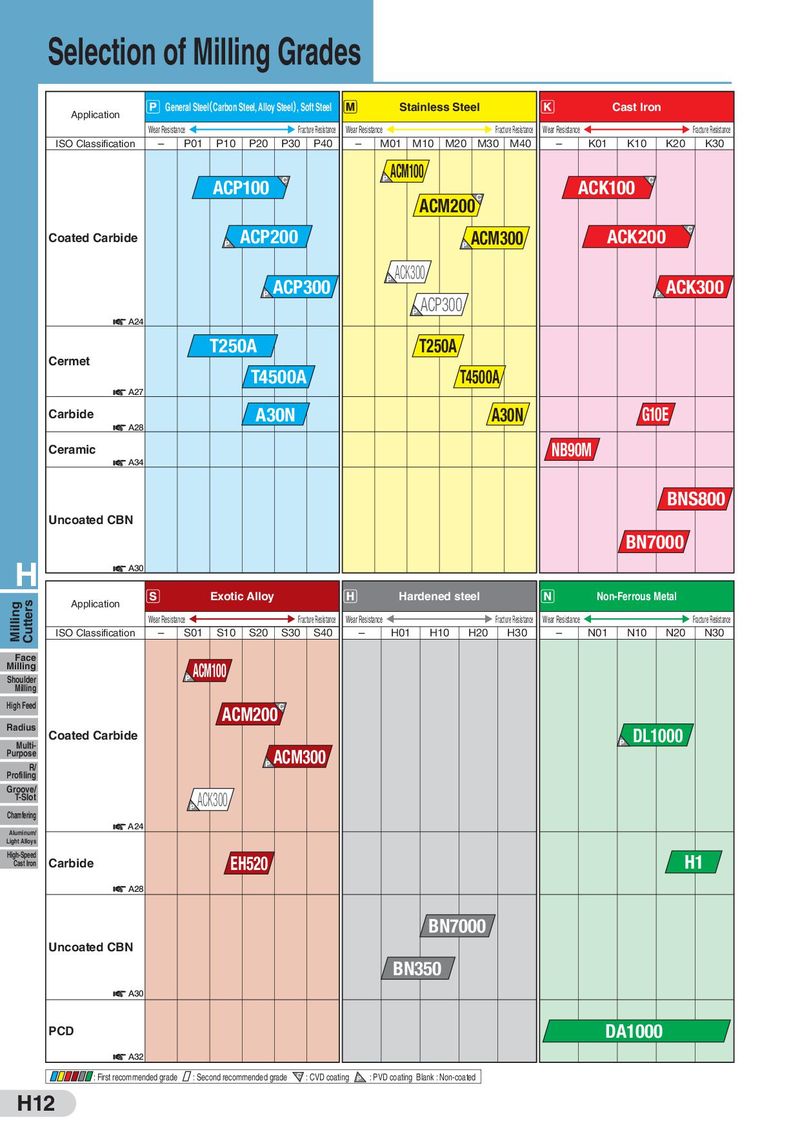

Selection of Milling Grades Application General Stee(l Carbon Steel, Alloy Steel), Soft Steel Stainless Steel Cast Iron Wear Resistance Fracture Resistance Wear Resistance Fracture Resistance Wear Resistance Fracture Resistance ISO Classification - P01 P10 P20 P30 P40 - M01 M10 M20 M30 M40 - K01 K10 K20 K30 P ACM100 ACP100 C ACK100 C ACM200C ACP200 ACM300 ACK200 C Coated Carbide P P P ACK300 P ACP300 P ACK300 P ACP300 A24 T250A T250A Cermet T4500A T4500A A27 Carbide A30N A30N G10E A28 Ceramic NB90M A34 BNS800 Uncoated CBN BN7000 H A30 Milling Cutters Application Exotic Alloy Hardened steel Non-Ferrous Metal Wear Resistance Fracture Resistance Wear Resistance Fracture Resistance Wear Resistance Fracture Resistance ISO Classification - S01 S10 S20 S30 S40 - H01 H10 H20 H30 - N01 N10 N20 N30 Face Milling ACM100 Shoulder P Milling High Feed ACM200C Radius Coated Carbide DL1000 Multi- P Purpose ACM300 R/ P Profiling Groove/ ACK300 T-Slot P Chamfering Aluminum/ A24 Light Alloys High-Speed Carbide EH520 H1 Cast Iron A28 BN7000 Uncoated CBN BN350 A30 PCD DA1000 A32 : First recommended grade : Second recommended grade C : CVD coating P : PVD coating Blank : Non-coated H12

Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo модульные системы для револьверных головок токарных станков

Каталог Sumitomo модульные системы для револьверных головок токарных станков Каталог Sumitomo токарные резцы (державки) для внутреннего точения

Каталог Sumitomo токарные резцы (державки) для внутреннего точения Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019 Каталог Sumitomo монолитные фрезы

Каталог Sumitomo монолитные фрезы