Каталог Sumitomo фрезы со сменными пластинами - страница 42

Навигация

- H001

- H002

- H003

- H004

- H005

- H006

- H007

- H008

- H009

- H010

- H011

- H012

- H013

- H014

- H015

- H016

- H017

- H018

- H019

- H020

- H021

- H022

- H023

- H024

- H025

- H026

- H027

- H028

- H029

- H030

- H031

- H032

- H033

- H034

- H035

- H036

- H037

- H038

- H039

- H040

- H041

- H042

- H043

- H044

- H045

- H046

- H047

- H048

- H049

- H050

- H051

- H052

- H053

- H054

- H055

- H056

- H057

- H058

- H059

- H060

- H061

- H062

- H063

- H064

- H065

- H066

- H067

- H068

- H069

- H070

- H071

- H072

- H073

- H074

- H075

- H076

- H077

- H078

- H079

- H080

- H081

- H082

- H083

- H084

- H085

- H086

- H087

- H088

- H089

- H090

- H091

- H092

- H093

- H094

- H095

- H096

- H097

- H098

- H099

- H100

- H101

- H102

- H103

- H104

- H105

- H106

- H107

- H108

- H109

- H110

- H111

- H112

- H113

- H114

- H115

- H116

- H117

- H118

- H119

- H120

- H121

- H122

- H123

- H124

- H125

- H126

- H127

- H128

- H129

- H130

- H131

- H132

- H133

- H134

- H135

- H136

- H137

- H138

- H139

- H140

- H141

- H142

- H143

- H144

- H145

- H146

- H147

- H148

- H149

- H150

- H151

- H152

- H153

- H154

- H155

- H156

- H157

- H158

- H159

- H160

- H161

- H162

- H163

- H164

- H165

- H166

- H167

- H168

- H169

- H170

- H171

- H172

- H173

- H174

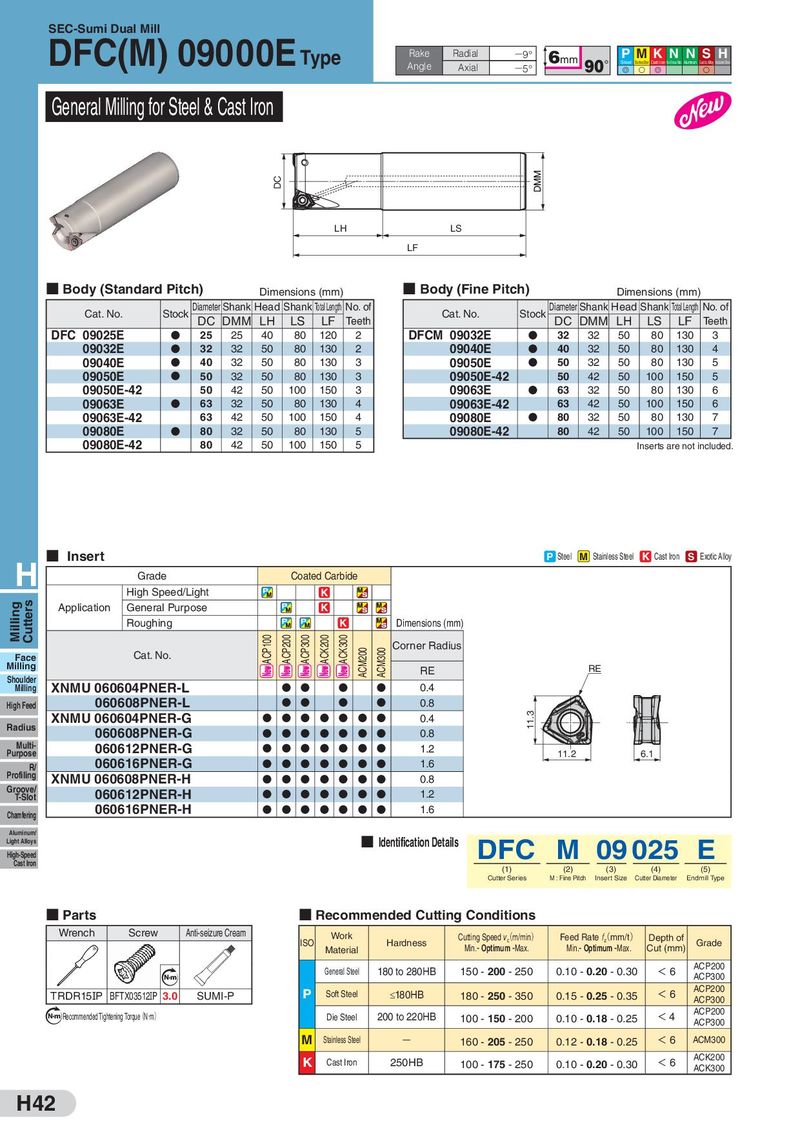

SEC-Sumi Dual Mill DFC(M) 09000EType Rake Radial −9° 6mm P M KN N SH Angle Axial 90° Steel Stainless Steel Cast Iron Non-Ferrous Metal Aluminum Exotic Alloy Hardened Steel −5° G S G S General Milling for Steel & Cast Iron DC DMM LH LS LF ■ Body (Standard Pitch) Dimensions (mm) ■ Body (Fine Pitch) Dimensions (mm) Cat. No. Stock Diameter Shank Head Shank Total Length No. of Cat. No. Stock Diameter Shank Head Shank Total Length No. of DC DMM LH LS LF Teeth DC DMM LH LS LF Teeth DFC 09025E D 25 25 40 80 120 2 DFCM 09032E D 32 32 50 80 130 3 09032E D 32 32 50 80 130 2 09040E D 40 32 50 80 130 4 09040E D 40 32 50 80 130 3 09050E D 50 32 50 80 130 5 09050E D 50 32 50 80 130 3 09050E-42 50 42 50 100 150 5 09050E-42 50 42 50 100 150 3 09063E D 63 32 50 80 130 6 09063E D 63 32 50 80 130 4 09063E-42 63 42 50 100 150 6 09063E-42 63 42 50 100 150 4 09080E D 80 32 50 80 130 7 09080E D 80 32 50 80 130 5 09080E-42 80 42 50 100 150 7 09080E-42 80 42 50 100 150 5 Inserts are not included. ■ Insert P Steel M Stainless Steel K Cast Iron S Exotic Alloy H Grade Coated Carbide High Speed/Light K Milling Cutters Application General Purpose K Roughing K Dimensions (mm) Cat. No. ACP100 ACP200 ACP300 ACK200 ACK300 ACM200 ACM300 Corner Radius Face Milling RE RE Shoulder XNMU 060604PNER-L D D D D 0.4 Milling High Feed 060608PNER-L D D D D 0.8 XNMU 060604PNER-G D D D D D D D 0.4 11.3 Radius 060608PNER-G D D D D D D D 0.8 Multi- 060612PNER-G D D D D D D D 1.2 Purpose 11.2 6.1 R/ 060616PNER-G D D D D D D D 1.6 Profiling XNMU 060608PNER-H D D D D D D D 0.8 Groove/ 060612PNER-H D D D D D D D 1.2 T-Slot Chamfering 060616PNER-H D D D D D D D 1.6 Aluminum/ ■ Identification Details Light Alloys DFC M 09 025 E High-Speed Cast Iron (1) (2) (3) (4) (5) Cutter Series M : Fine Pitch Insert Size Cutter Diameter Endmill Type ■ Parts ■ Recommended Cutting Conditions Wrench Screw Anti-seizure Cream Work Cutting Speed v(c m/min) Feed Rate f(z mm/t) Depth of ISO Material Hardness Min.- Optimum -Max. Min.- Optimum -Max. Cut (mm) Grade General Steel 180 to 280HB 150 - 200 - 250 0.10 - 0.20 - 0.30 <6 ACP200 Nm ACP300 TRDR15IP BFTX03512IP 3.0 SUMI-P P Soft Steel ≤180HB 180 - 250 - 350 0.15 - 0.25 - 0.35 <6 ACP200 ACP300 N m Recommended Tightening Torque(N・m) Die Steel 200 to 220HB 100 - 150 - 200 0.10 - 0.18 - 0.25 <4 ACP200 ACP300 M Stainless Steel − 160 - 205 - 250 0.12 - 0.18 - 0.25 <6 ACM300 K Cast Iron 250HB 100 - 175 - 250 0.10 - 0.20 - 0.30 <6 ACK200 ACK300 H42

Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo модульные системы для револьверных головок токарных станков

Каталог Sumitomo модульные системы для револьверных головок токарных станков Каталог Sumitomo токарные резцы (державки) для внутреннего точения

Каталог Sumitomo токарные резцы (державки) для внутреннего точения Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019 Каталог Sumitomo монолитные фрезы

Каталог Sumitomo монолитные фрезы