Каталог Sumitomo фрезы со сменными пластинами - страница 131

Навигация

- H001

- H002

- H003

- H004

- H005

- H006

- H007

- H008

- H009

- H010

- H011

- H012

- H013

- H014

- H015

- H016

- H017

- H018

- H019

- H020

- H021

- H022

- H023

- H024

- H025

- H026

- H027

- H028

- H029

- H030

- H031

- H032

- H033

- H034

- H035

- H036

- H037

- H038

- H039

- H040

- H041

- H042

- H043

- H044

- H045

- H046

- H047

- H048

- H049

- H050

- H051

- H052

- H053

- H054

- H055

- H056

- H057

- H058

- H059

- H060

- H061

- H062

- H063

- H064

- H065

- H066

- H067

- H068

- H069

- H070

- H071

- H072

- H073

- H074

- H075

- H076

- H077

- H078

- H079

- H080

- H081

- H082

- H083

- H084

- H085

- H086

- H087

- H088

- H089

- H090

- H091

- H092

- H093

- H094

- H095

- H096

- H097

- H098

- H099

- H100

- H101

- H102

- H103

- H104

- H105

- H106

- H107

- H108

- H109

- H110

- H111

- H112

- H113

- H114

- H115

- H116

- H117

- H118

- H119

- H120

- H121

- H122

- H123

- H124

- H125

- H126

- H127

- H128

- H129

- H130

- H131

- H132

- H133

- H134

- H135

- H136

- H137

- H138

- H139

- H140

- H141

- H142

- H143

- H144

- H145

- H146

- H147

- H148

- H149

- H150

- H151

- H152

- H153

- H154

- H155

- H156

- H157

- H158

- H159

- H160

- H161

- H162

- H163

- H164

- H165

- H166

- H167

- H168

- H169

- H170

- H171

- H172

- H173

- H174

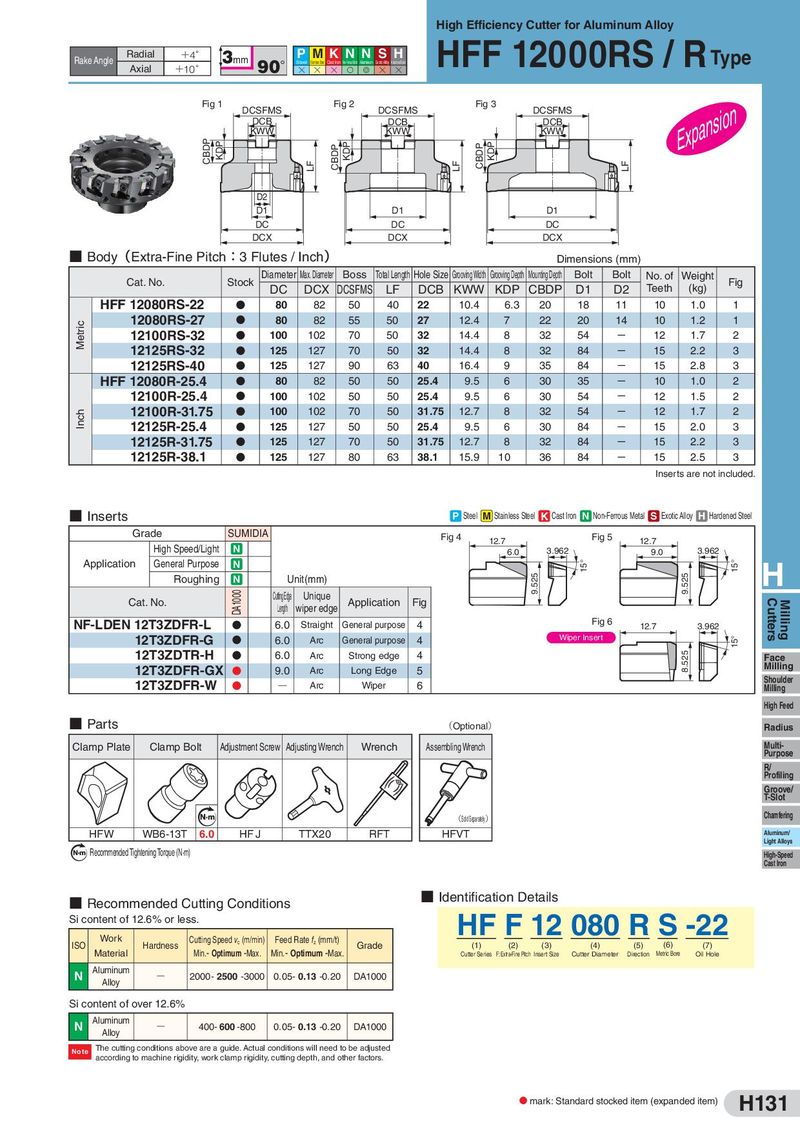

High Efficiency Cutter for Aluminum Alloy Rake Angle Radial +4° 3mm P M KN N SH HFF 12000RS / RType Axial 90°Steel Stainless Steel Cast Iron Non-Ferrous Metal Aluminum Exotic Alloy Hardened Steel +10° H H H S G H H Fig 1 DCSFMS Fig 2 DCSFMS Fig 3 DCSFMS Expansion DCB DCB DCB KWW KWW KWW CBDP KDP CBDP KDP CBDP KDP LF LF LF D2 D1 D1 D1 DC DC DC DCX DCX DCX ■ Body(Extra-Fine Pitch:3 Flutes / Inch) Dimensions (mm) Cat. No. Stock Diameter Max. Diameter Boss Total Length Hole Size Grooving Width Grooving Depth Mounting Depth Bolt Bolt No. of Weight Fig DC DCX DCSFMS LF DCB KWW KDP CBDP D1 D2 Teeth (kg) HFF 12080RS-22 D 80 82 50 40 22 10.4 6.3 20 18 11 10 1.0 1 Metric 12080RS-27 D 80 82 55 50 27 12.4 7 22 20 14 10 1.2 1 12100RS-32 D 100 102 70 50 32 14.4 8 32 54 − 12 1.7 2 12125RS-32 D 125 127 70 50 32 14.4 8 32 84 − 15 2.2 3 12125RS-40 D 125 127 90 63 40 16.4 9 35 84 − 15 2.8 3 HFF 12080R-25.4 D 80 82 50 50 25.4 9.5 6 30 35 − 10 1.0 2 12100R-25.4 D 100 102 50 50 25.4 9.5 6 30 54 − 12 1.5 2 Inch 12100R-31.75 D 100 102 70 50 31.75 12.7 8 32 54 − 12 1.7 2 12125R-25.4 D 125 127 50 50 25.4 9.5 6 30 84 − 15 2.0 3 12125R-31.75 D 125 127 70 50 31.75 12.7 8 32 84 − 15 2.2 3 12125R-38.1 D 125 127 80 63 38.1 15.9 10 36 84 − 15 2.5 3 Inserts are not included. ■ Inserts P Steel M Stainless Steel K Cast Iron N Non-Ferrous Metal S Exotic Alloy H Hardened Steel Grade SUMIDIA Fig 4 12.7 Fig 5 12.7 High Speed/Light N 6.0 3.962 9.0 3.962 Application General Purpose N 15° 15° H Roughing N Unit(mm) 9.525 9.525 Cat. No. DA1000 Cut ing Edge Unique Application Fig Cutters Milling Length wiper edge NF-LDEN 12T3ZDFR-L D 6.0 Straight General purpose 4 Fig 6 12.7 3.962 12T3ZDFR-G D 6.0 Arc General purpose 4 Wiper Insert 15° 12T3ZDTR-H D 6.0 Arc Strong edge 4 8.525 Face 12T3ZDFR-GX D 9.0 Arc Long Edge 5 Milling 12T3ZDFR-W D Q Arc Wiper 6 Shoulder Milling High Feed ■ Parts (Optional) Radius Clamp Plate Clamp Bolt Adjustment Screw Adjusting Wrench Wrench Assembling Wrench Multi- Purpose R/ Profiling Groove/ T-Slot Nm (Sold Separately) Chamfering HFW WB6-13T 6.0 HF J TTX20 RFT HFVT Aluminum/ Light Alloys N m Recommended Tightening Torque (N·m) High-Speed Cast Iron ■ Recommended Cutting Conditions ■ Identification Details Si content of 12.6% or less. HF F 12 080 R S -22 ISO Work Hardness Cutting Speed vc (m/min) Feed Rate fz (mm/t) Grade (1) (2) (3) (4) (5) (6) (7) Material Min.- Optimum -Max. Min.- Optimum -Max. Cutter Series F: Extra-Fine Pitch Insert Size Cutter Diameter Direction Metric Bore Oil Hole N Aluminum Q 2000- 2500 -3000 0.05- 0.13 -0.20 DA1000 Alloy Si content of over 12.6% N Aluminum Q 400- 600 -800 0.05- 0.13 -0.20 DA1000 Alloy Note The cutting conditions above are a guide. Actual conditions will need to be adjusted according to machine rigidity, work clamp rigidity, cutting depth, and other factors. D mark: Standard stocked item (expanded item) H131

Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo модульные системы для револьверных головок токарных станков

Каталог Sumitomo модульные системы для револьверных головок токарных станков Каталог Sumitomo токарные резцы (державки) для внутреннего точения

Каталог Sumitomo токарные резцы (державки) для внутреннего точения Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019 Каталог Sumitomo монолитные фрезы

Каталог Sumitomo монолитные фрезы