Каталог Sumitomo фрезы со сменными пластинами - страница 80

Навигация

- H001

- H002

- H003

- H004

- H005

- H006

- H007

- H008

- H009

- H010

- H011

- H012

- H013

- H014

- H015

- H016

- H017

- H018

- H019

- H020

- H021

- H022

- H023

- H024

- H025

- H026

- H027

- H028

- H029

- H030

- H031

- H032

- H033

- H034

- H035

- H036

- H037

- H038

- H039

- H040

- H041

- H042

- H043

- H044

- H045

- H046

- H047

- H048

- H049

- H050

- H051

- H052

- H053

- H054

- H055

- H056

- H057

- H058

- H059

- H060

- H061

- H062

- H063

- H064

- H065

- H066

- H067

- H068

- H069

- H070

- H071

- H072

- H073

- H074

- H075

- H076

- H077

- H078

- H079

- H080

- H081

- H082

- H083

- H084

- H085

- H086

- H087

- H088

- H089

- H090

- H091

- H092

- H093

- H094

- H095

- H096

- H097

- H098

- H099

- H100

- H101

- H102

- H103

- H104

- H105

- H106

- H107

- H108

- H109

- H110

- H111

- H112

- H113

- H114

- H115

- H116

- H117

- H118

- H119

- H120

- H121

- H122

- H123

- H124

- H125

- H126

- H127

- H128

- H129

- H130

- H131

- H132

- H133

- H134

- H135

- H136

- H137

- H138

- H139

- H140

- H141

- H142

- H143

- H144

- H145

- H146

- H147

- H148

- H149

- H150

- H151

- H152

- H153

- H154

- H155

- H156

- H157

- H158

- H159

- H160

- H161

- H162

- H163

- H164

- H165

- H166

- H167

- H168

- H169

- H170

- H171

- H172

- H173

- H174

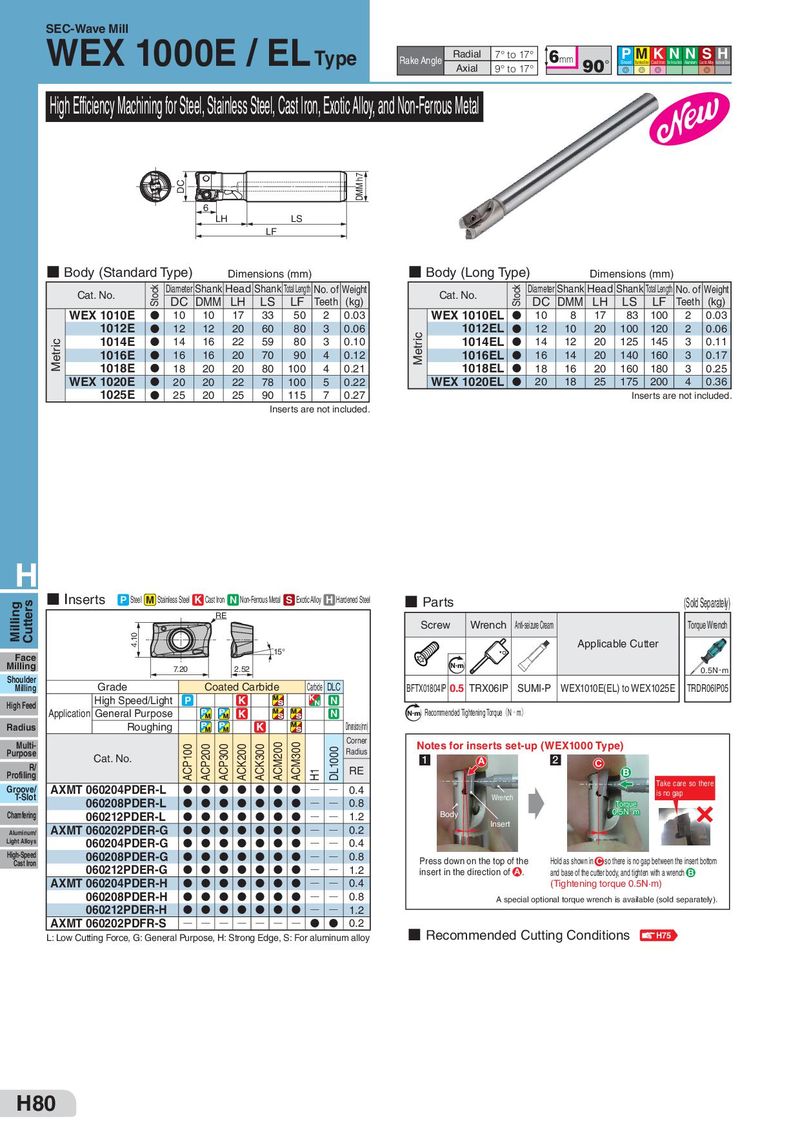

SEC-Wave Mill WEX 1000E / EL Type Rake Angle Radial 7° to 17° 6mm P MKN N SH 90°Steel Axial 9° to 17° Stainless Steel Cast Iron Non-Ferrous Metal Aluminum Exotic Alloy Hardened Steel G G G G High Eficiency Machining for Steel, Stainless Steel, Cast Iron, ExoticAloy, and Non-Ferrous Metal DC DMM h7 6 LH LS LF ■ Body (Standard Type) Dimensions (mm) ■ Body (Long Type) Dimensions (mm) Cat. No. Stock Diameter Shank Head Shank Total Length No. of Weight Cat. No. Stock Diameter Shank Head Shank Total Length No. of Weight DC DMM LH LS LF Teeth (kg) DC DMM LH LS LF Teeth (kg) WEX 1010E D 10 10 17 33 50 2 0.03 WEX 1010EL D 10 8 17 83 100 2 0.03 1012E D 12 12 20 60 80 3 0.06 Metric 1012EL D 12 10 20 100 120 2 0.06 Metric 1014E D 14 16 22 59 80 3 0.10 1014EL D 14 12 20 125 145 3 0.11 1016E D 16 16 20 70 90 4 0.12 1016EL D 16 14 20 140 160 3 0.17 1018E D 18 20 20 80 100 4 0.21 1018EL D 18 16 20 160 180 3 0.25 WEX 1020E D 20 20 22 78 100 5 0.22 WEX 1020EL D 20 18 25 175 200 4 0.36 1025E D 25 20 25 90 115 7 0.27 Inserts are not included. Inserts are not included. H Milling Cutters ■ Inserts P Steel M Stainless Steel K Cast Iron N Non-Ferrous Metal S Exotic Alloy H Hardened Steel ■ Parts (Sold Separately) RE Screw Wrench Anti-seizure Cream Torque Wrench 4.10 Applicable Cutter Face 15° Milling 7.20 2.52 Nm 0.5N・m Shoulder Grade Coated Carbide Carbide DLC BFTX01804IP 0.5 TRX06IP SUMI-P WEX1010E(EL) to WEX1025E TRDR06IP05 Milling High Feed High Speed/Light P K N Application General Purpose K N N m Recommended Tightening Torque(N・m) Radius Roughing K Dimensions (mm) Multi- ACP100 ACP200 ACP300 ACK200 ACK300 ACM200 ACM300 Corner Notes for inserts set-up (WEX1000 Type) Purpose Cat. No. DL1000 Radius 1 2 R/ A C Profiling H1 RE B Groove/ AXMT 060204PDER-L D D D D D D D Q Q 0.4 Take care so there T-Slot Wrench is no gap 060208PDER-L D D D D D D D Q Q 0.8 Torque Chamfering 060212PDER-L D D D D D D D Q Q 1.2 Body 0.5N・m AXMT 060202PDER-G D D D D D D D Q Q 0.2 Insert Aluminum/ Light Alloys 060204PDER-G D D D D D D D Q Q 0.4 High-Speed 060208PDER-G D D D D D D D Q Q 0.8 Press down on the top of the Hold as shown in C so there is no gap between the insert bottom Cast Iron 060212PDER-G D D D D D D D Q Q 1.2 insert in the direction of A . and base of the cutter body, and tighten with a wrench B AXMT 060204PDER-H D D D D D D D Q Q 0.4 (Tightening torque 0.5N·m) 060208PDER-H D D D D D D D Q Q 0.8 A special optional torque wrench is available (sold separately). 060212PDER-H D D D D D D D Q Q 1.2 AXMT 060202PDFR-S Q Q Q Q Q Q Q D D 0.2 L: Low Cutting Force, G: General Purpose, H: Strong Edge, S: For aluminum alloy ■ Recommended Cutting Conditions H75 HH80

Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo модульные системы для револьверных головок токарных станков

Каталог Sumitomo модульные системы для револьверных головок токарных станков Каталог Sumitomo токарные резцы (державки) для внутреннего точения

Каталог Sumitomo токарные резцы (державки) для внутреннего точения Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019 Каталог Sumitomo монолитные фрезы

Каталог Sumitomo монолитные фрезы