Каталог Sumitomo фрезы со сменными пластинами - страница 109

Навигация

- H001

- H002

- H003

- H004

- H005

- H006

- H007

- H008

- H009

- H010

- H011

- H012

- H013

- H014

- H015

- H016

- H017

- H018

- H019

- H020

- H021

- H022

- H023

- H024

- H025

- H026

- H027

- H028

- H029

- H030

- H031

- H032

- H033

- H034

- H035

- H036

- H037

- H038

- H039

- H040

- H041

- H042

- H043

- H044

- H045

- H046

- H047

- H048

- H049

- H050

- H051

- H052

- H053

- H054

- H055

- H056

- H057

- H058

- H059

- H060

- H061

- H062

- H063

- H064

- H065

- H066

- H067

- H068

- H069

- H070

- H071

- H072

- H073

- H074

- H075

- H076

- H077

- H078

- H079

- H080

- H081

- H082

- H083

- H084

- H085

- H086

- H087

- H088

- H089

- H090

- H091

- H092

- H093

- H094

- H095

- H096

- H097

- H098

- H099

- H100

- H101

- H102

- H103

- H104

- H105

- H106

- H107

- H108

- H109

- H110

- H111

- H112

- H113

- H114

- H115

- H116

- H117

- H118

- H119

- H120

- H121

- H122

- H123

- H124

- H125

- H126

- H127

- H128

- H129

- H130

- H131

- H132

- H133

- H134

- H135

- H136

- H137

- H138

- H139

- H140

- H141

- H142

- H143

- H144

- H145

- H146

- H147

- H148

- H149

- H150

- H151

- H152

- H153

- H154

- H155

- H156

- H157

- H158

- H159

- H160

- H161

- H162

- H163

- H164

- H165

- H166

- H167

- H168

- H169

- H170

- H171

- H172

- H173

- H174

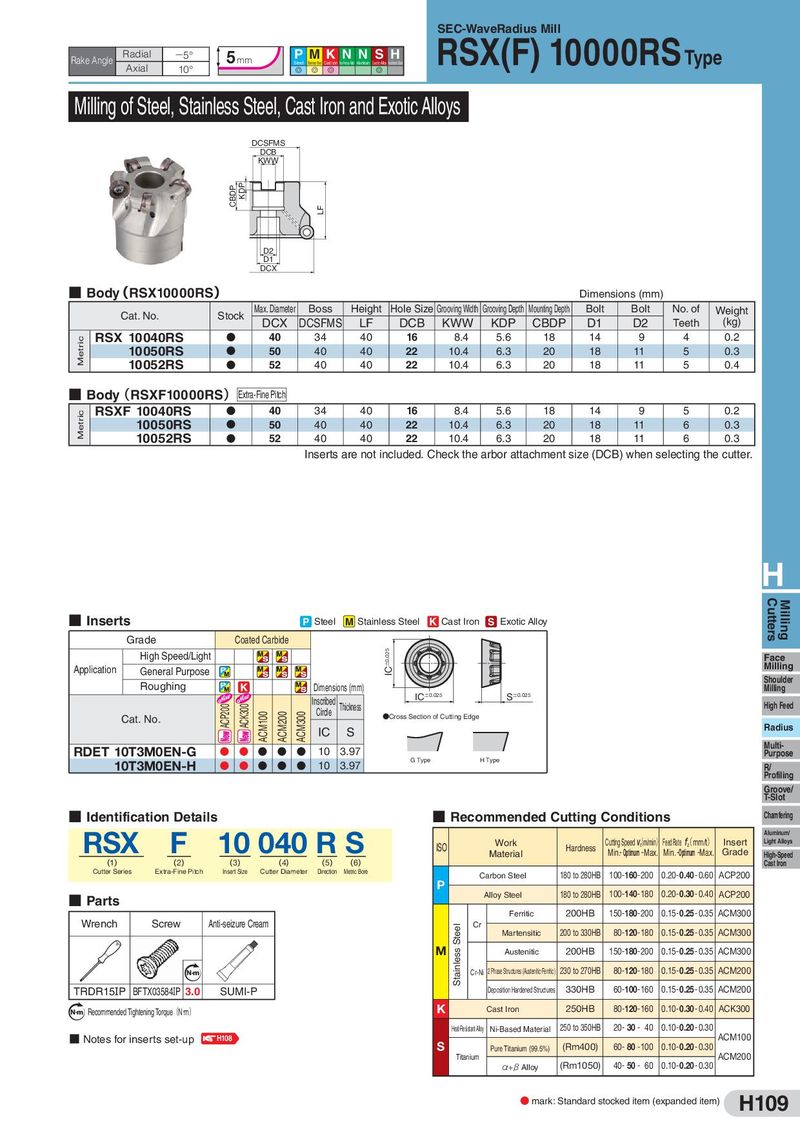

SEC-WaveRadius Mill Rake Angle Radial −5° 5 mm P MKN N SH RSX(F) 10000RSType Axial Steel Stainless Steel Cast Iron Non-Ferrous Metal Aluminum Exotic Alloy Hardened Steel 10° G G G G Milling of Steel, Stainless Steel, Cast Iron and Exotic Alloys DCSFMS DCB KWW CBDP KDP LF D2 D1 DCX ■ Body(RSX10000RS) Dimensions (mm) Cat. No. Stock Max. Diameter Boss Height Hole Size Grooving Width Grooving Depth Mounting Depth Bolt Bolt No. of Weight DCX DCSFMS LF DCB KWW KDP CBDP D1 D2 Teeth (kg) Metric RSX 10040RS D 40 34 40 16 8.4 5.6 18 14 9 4 0.2 10050RS D 50 40 40 22 10.4 6.3 20 18 11 5 0.3 10052RS D 52 40 40 22 10.4 6.3 20 18 11 5 0.4 ■ Body(RSXF10000RS) Extra-Fine Pitch Metric RSXF 10040RS D 40 34 40 16 8.4 5.6 18 14 9 5 0.2 10050RS D 50 40 40 22 10.4 6.3 20 18 11 6 0.3 10052RS D 52 40 40 22 10.4 6.3 20 18 11 6 0.3 Inserts are not included. Check the arbor attachment size (DCB) when selecting the cutter. H ■ Inserts P Steel M Stainless Steel K Cast Iron S Exotic Alloy Cutters Milling Grade Coated Carbide High Speed/Light IC±0.025 Face Application General Purpose Milling Roughing K Dimensions (mm) Shoulder Milling Inscribed IC±0.025 S±0.025 ACP200 ACK300 Circle Thickness High Feed Cat. No. ACM100 ACM200 ACM300 ●Cross Section of Cutting Edge IC S Radius RDET 10T3M0EN-G D D D D D 10 3.97 Multi- Purpose G Type H Type 10T3M0EN-H D D D D D 10 3.97 R/ Profiling Groove/ T-Slot ■ Identification Details ■ Recommended Cutting Conditions Chamfering RSX F 10 040 R S Aluminum/ ISO Work Hardness Cutting Speed (c m/min) Feed Rate (z mm/t) Insert Light Alloys Material Min.- Optimum -Max. Min.-Optimum -Max. Grade High-Speed (1) (2) (3) (4) (5) (6) Cast Iron Cutter Series Extra-Fine Pitch Insert Size Cutter Diameter Direction Metric Bore Carbon Steel 180 to 280HB 100-160-200 0.20-0.40- 0.60 ACP200 P 180 to 280HB 100-140-180 0.20-0.30- 0.40 ACP200 ■ Parts Alloy Steel Ferritic 200HB 150-180-200 0.15-0.25- 0.35 ACM300 Wrench Screw Anti-seizure Cream Stainless Steel Cr 200 to 330HB 80-120-180 0.15-0.25- 0.35 ACM300 Martensitic M Austenitic 200HB 150-180-200 0.15-0.25- 0.35 ACM300 Nm Cr-Ni 2 Phase Structures (Austenitic・Ferritic) 230 to 270HB 80-120-180 0.15-0.25- 0.35 ACM200 TRDR15IP BFTX03584IP 3.0 SUMI-P Deposition Hardened Structures 330HB 60-100-160 0.15-0.25- 0.35 ACM200 N m Recommended Tightening Torque(N・m) K Cast Iron 250HB 80-120-160 0.10-0.30- 0.40 ACK300 Heat-Resistant Aloy Ni-Based Material 250 to 350HB 20- 30 - 40 0.10-0.20- 0.30 ■ Notes for inserts set-up H108 ACM100 S Pure Titanium (99.5%) (Rm400) 60- 80 -100 0.10-0.20- 0.30 Titanium ACM200 α+β Alloy (Rm1050) 40- 50 - 60 0.10-0.20- 0.30 ● mark: Standard stocked item (expanded item) H109

Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo модульные системы для револьверных головок токарных станков

Каталог Sumitomo модульные системы для револьверных головок токарных станков Каталог Sumitomo токарные резцы (державки) для внутреннего точения

Каталог Sumitomo токарные резцы (державки) для внутреннего точения Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019 Каталог Sumitomo монолитные фрезы

Каталог Sumitomo монолитные фрезы