Каталог Sumitomo фрезы со сменными пластинами - страница 138

Навигация

- H001

- H002

- H003

- H004

- H005

- H006

- H007

- H008

- H009

- H010

- H011

- H012

- H013

- H014

- H015

- H016

- H017

- H018

- H019

- H020

- H021

- H022

- H023

- H024

- H025

- H026

- H027

- H028

- H029

- H030

- H031

- H032

- H033

- H034

- H035

- H036

- H037

- H038

- H039

- H040

- H041

- H042

- H043

- H044

- H045

- H046

- H047

- H048

- H049

- H050

- H051

- H052

- H053

- H054

- H055

- H056

- H057

- H058

- H059

- H060

- H061

- H062

- H063

- H064

- H065

- H066

- H067

- H068

- H069

- H070

- H071

- H072

- H073

- H074

- H075

- H076

- H077

- H078

- H079

- H080

- H081

- H082

- H083

- H084

- H085

- H086

- H087

- H088

- H089

- H090

- H091

- H092

- H093

- H094

- H095

- H096

- H097

- H098

- H099

- H100

- H101

- H102

- H103

- H104

- H105

- H106

- H107

- H108

- H109

- H110

- H111

- H112

- H113

- H114

- H115

- H116

- H117

- H118

- H119

- H120

- H121

- H122

- H123

- H124

- H125

- H126

- H127

- H128

- H129

- H130

- H131

- H132

- H133

- H134

- H135

- H136

- H137

- H138

- H139

- H140

- H141

- H142

- H143

- H144

- H145

- H146

- H147

- H148

- H149

- H150

- H151

- H152

- H153

- H154

- H155

- H156

- H157

- H158

- H159

- H160

- H161

- H162

- H163

- H164

- H165

- H166

- H167

- H168

- H169

- H170

- H171

- H172

- H173

- H174

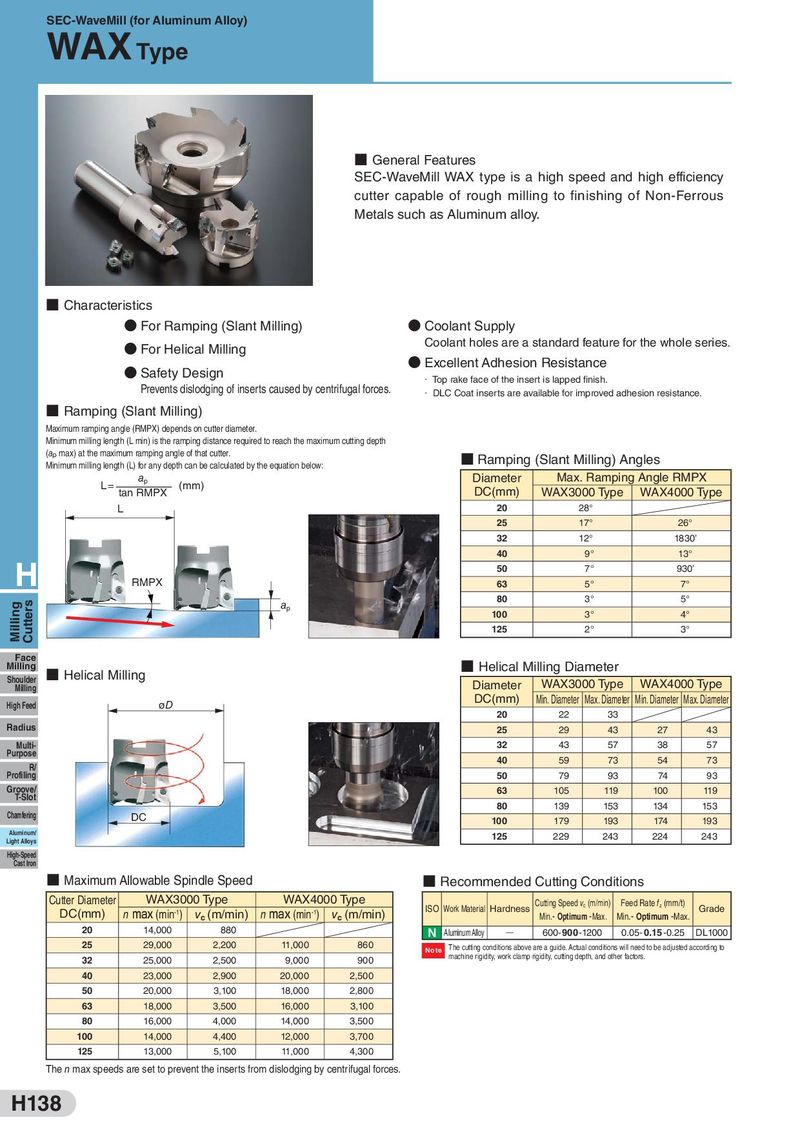

SEC-WaveMill (for Aluminum Alloy) WAX Type ■ General Features SEC-WaveMill WAX type is a high speed and high efficiency cutter capable of rough milling to finishing of Non-Ferrous Metals such as Aluminum alloy. ■ Characteristics ● For Ramping (Slant Milling) ● Coolant Supply ● For Helical Milling Coolant holes are a standard feature for the whole series. ● Safety Design ● Excellent Adhesion Resistance Prevents dislodging of inserts caused by centrifugal forces. ・ Top rake face of the insert is lapped finish. ・ DLC Coat inserts are available for improved adhesion resistance. ■ Ramping (Slant Milling) Maximum ramping angle (RMPX) depends on cutter diameter. Minimum milling length (L min) is the ramping distance required to reach the maximum cutting depth (ap max) at the maximum ramping angle of that cutter. ■ Ramping (Slant Milling) Angles Minimum milling length (L) for any depth can be calculated by the equation below: L= ap (mm) Diameter Max. Ramping Angle RMPX tan RMPX DC(mm) WAX3000 Type WAX4000 Type L 20 28° 25 17° 26° 32 12° 1830’ 40 9° 13° H 50 7° 930’ RMPX 63 5° 7° Milling Cutters ap 80 3° 5° 100 3° 4° 125 2° 3° Face ■ Helical Milling Diameter Milling ■ Helical Milling Shoulder Diameter WAX3000 Type WAX4000 Type Milling High Feed øD DC(mm) Min. Diameter Max. Diameter Min. Diameter Max. Diameter 20 22 33 Radius 25 29 43 27 43 Multi- 32 43 57 38 57 Purpose 40 59 73 54 73 R/ Profiling 50 79 93 74 93 Groove/ 63 105 119 100 119 T-Slot 139 153 134 153 80 Chamfering DC 100 179 193 174 193 Aluminum/ 125 229 243 224 243 Light Alloys High-Speed Cast Iron ■ Maximum Allowable Spindle Speed ■ Recommended Cutting Conditions Cutter Diameter WAX3000 Type WAX4000 Type ISO Work Material Hardness Cutting Speed vc (m/min) Feed Rate fz (mm/t) Grade DC(mm) n max (min-1) vc (m/min) n max (min-1) vc (m/min) Min.- Optimum -Max. Min.- Optimum -Max. 20 14,000 880 N Aluminum Alloy Q 600-900-1200 0.05- 0.15 -0.25 DL1000 25 29,000 2,200 11,000 860 Note The cutting conditions above are a guide. Actual conditions will need to be adjusted according to 32 25,000 2,500 9,000 900 machine rigidity, work clamp rigidity, cutting depth, and other factors. 40 23,000 2,900 20,000 2,500 50 20,000 3,100 18,000 2,800 63 18,000 3,500 16,000 3,100 80 16,000 4,000 14,000 3,500 100 14,000 4,400 12,000 3,700 125 13,000 5,100 11,000 4,300 The n max speeds are set to prevent the inserts from dislodging by centrifugal forces. H138

Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo модульные системы для револьверных головок токарных станков

Каталог Sumitomo модульные системы для револьверных головок токарных станков Каталог Sumitomo токарные резцы (державки) для внутреннего точения

Каталог Sumitomo токарные резцы (державки) для внутреннего точения Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019 Каталог Sumitomo монолитные фрезы

Каталог Sumitomo монолитные фрезы