Каталог Sumitomo фрезы со сменными пластинами - страница 141

Навигация

- H001

- H002

- H003

- H004

- H005

- H006

- H007

- H008

- H009

- H010

- H011

- H012

- H013

- H014

- H015

- H016

- H017

- H018

- H019

- H020

- H021

- H022

- H023

- H024

- H025

- H026

- H027

- H028

- H029

- H030

- H031

- H032

- H033

- H034

- H035

- H036

- H037

- H038

- H039

- H040

- H041

- H042

- H043

- H044

- H045

- H046

- H047

- H048

- H049

- H050

- H051

- H052

- H053

- H054

- H055

- H056

- H057

- H058

- H059

- H060

- H061

- H062

- H063

- H064

- H065

- H066

- H067

- H068

- H069

- H070

- H071

- H072

- H073

- H074

- H075

- H076

- H077

- H078

- H079

- H080

- H081

- H082

- H083

- H084

- H085

- H086

- H087

- H088

- H089

- H090

- H091

- H092

- H093

- H094

- H095

- H096

- H097

- H098

- H099

- H100

- H101

- H102

- H103

- H104

- H105

- H106

- H107

- H108

- H109

- H110

- H111

- H112

- H113

- H114

- H115

- H116

- H117

- H118

- H119

- H120

- H121

- H122

- H123

- H124

- H125

- H126

- H127

- H128

- H129

- H130

- H131

- H132

- H133

- H134

- H135

- H136

- H137

- H138

- H139

- H140

- H141

- H142

- H143

- H144

- H145

- H146

- H147

- H148

- H149

- H150

- H151

- H152

- H153

- H154

- H155

- H156

- H157

- H158

- H159

- H160

- H161

- H162

- H163

- H164

- H165

- H166

- H167

- H168

- H169

- H170

- H171

- H172

- H173

- H174

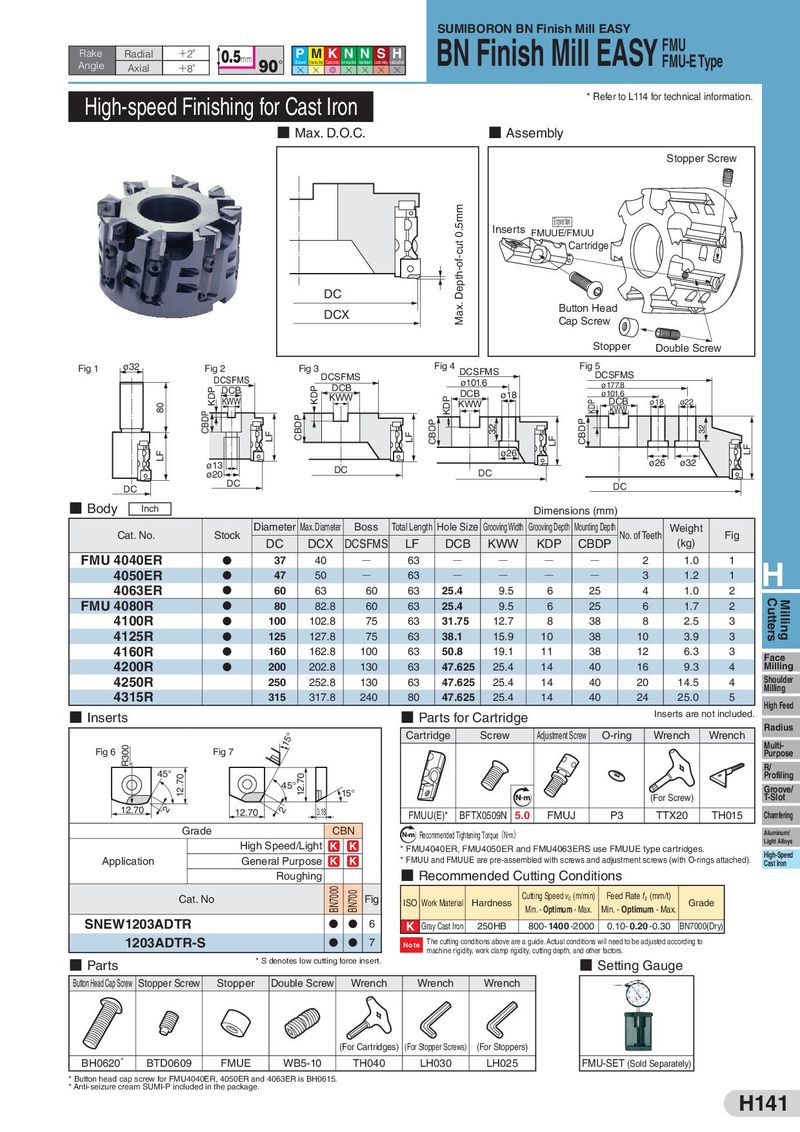

SUMIBORON BN Finish Mill EASY Rake Radial +2° 0.5mm P M K N N SH BN Finish Mill EASY FMU Angle Axial +8° 90° Steel Stainless Steel Cast Iron Non-Ferrous Metal Aluminum Exotic Alloy Hardened Steel FMU-E Type H H G H H H H High-speed Finishing for Cast Iron * Refer to L114 for technical information. ■ Max. D.O.C. ■ Assembly Stopper Screw Max. Depth-of-cut 0.5mm Inserts Engraved Mark FMUUE/FMUU Cartridge DC DCX Button Head Cap Screw Stopper Double Screw Fig 1 ø32 Fig 2 Fig 3 Fig 4 DCSFMS Fig 5 DCSFMS DCSFMS ø101.6 DCSFMS CBDP KDP DCB KDP DCB ø177.8 KWW KWW KDP DCB ø18 ø101.6 80 KWW KDP DCB ø18 ø22 CBDP KWW LF LF CBDP 32 CBDP 32 LF LF LF ø26 ø13 DC ø26 ø32 ø20 DC DC DC DC ■ Body Inch Dimensions (mm) Cat. No. Stock Diameter Max. Diameter Boss Total Length Hole Size Grooving Width Grooving Depth Mounting Depth No. of Teeth Weight Fig DC DCX DCSFMS LF DCB KWW KDP CBDP (kg) FMU 4040ER D 37 40 Q 63 Q Q Q Q 2 1.0 1 H 4050ER D 47 50 Q 63 Q Q Q Q 3 1.2 1 4063ER D 60 63 60 63 25.4 9.5 6 25 4 1.0 2 FMU 4080R D 80 82.8 60 63 25.4 9.5 6 25 カ 6 1.7 2 Cutters Milling 4100R D 100 102.8 75 63 31.75 12.7 8 38 ッ 8 2.5 3 4125R D 125 127.8 75 63 38.1 15.9 10 38 タ 10 3.9 3 4160R D 160 162.8 100 63 50.8 19.1 11 38 12 6.3 3 Face 4200R D 200 202.8 130 63 47.625 25.4 14 40 16 9.3 4 Milling 4250R 250 252.8 130 63 47.625 25.4 14 40 20 14.5 4 Shoulder Milling 4315R 315 317.8 240 80 47.625 25.4 14 40 24 25.0 5 High Feed ■ Inserts ■ Parts for Cartridge Inserts are not included. Cartridge Screw Adjustment Screw O-ring Wrench Wrench Radius R300 15° Multi- Fig 6 Fig 7 Purpose 45° R/ Profiling 12.70 12.70 45° 15° Groove/ Nm (For Screw) T-Slot 12.70 2 12.70 2 3.18 FMUU(E)* BFTX0509N 5.0 FMUJ P3 TTX20 TH015 Chamfering Grade CBN N m Recommended Tightening Torque(N・m) Aluminum/ High Speed/Light K K Light Alloys * FMU4040ER, FMU4050ER and FMU4063ERS use FMUUE type cartridges. High-Speed Application General Purpose K K * FMUU and FMUUE are pre-assembled with screws and adjustment screws (with O-rings attached). Cast Iron Roughing ■ Recommended Cutting Conditions Cat. No BN7000 BN700 Fig ISO Work Material Hardness Cutting Speed vc (m/min) Feed Rate fz (mm/t) Grade Min. - Optimum - Max. Min. - Optimum - Max. SNEW1203ADTR D D 6 K Gray Cast Iron 250HB 800- 1400 -2000 0.10- 0.20 -0.30 BN7000(Dry) 1203ADTR-S D D 7 Note The cutting conditions above are a guide. Actual conditions will need to be adjusted according to machine rigidity, work clamp rigidity, cutting depth, and other factors. ■ Parts * S denotes low cutting force insert. ■ Setting Gauge Button Head Cap Screw Stopper Screw Stopper Double Screw Wrench Wrench Wrench (For Cartridges) (For Stopper Screws) (For Stoppers) BH0620* BTD0609 FMUE WB5-10 TH040 LH030 LH025 FMU-SET (Sold Separately) * Button head cap screw for FMU4040ER, 4050ER and 4063ER is BH0615. * Anti-seizure cream SUMI-P included in the package. H141

Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo модульные системы для револьверных головок токарных станков

Каталог Sumitomo модульные системы для револьверных головок токарных станков Каталог Sumitomo токарные резцы (державки) для внутреннего точения

Каталог Sumitomo токарные резцы (державки) для внутреннего точения Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019 Каталог Sumitomo монолитные фрезы

Каталог Sumitomo монолитные фрезы