Каталог Sumitomo фрезы со сменными пластинами - страница 108

Навигация

- H001

- H002

- H003

- H004

- H005

- H006

- H007

- H008

- H009

- H010

- H011

- H012

- H013

- H014

- H015

- H016

- H017

- H018

- H019

- H020

- H021

- H022

- H023

- H024

- H025

- H026

- H027

- H028

- H029

- H030

- H031

- H032

- H033

- H034

- H035

- H036

- H037

- H038

- H039

- H040

- H041

- H042

- H043

- H044

- H045

- H046

- H047

- H048

- H049

- H050

- H051

- H052

- H053

- H054

- H055

- H056

- H057

- H058

- H059

- H060

- H061

- H062

- H063

- H064

- H065

- H066

- H067

- H068

- H069

- H070

- H071

- H072

- H073

- H074

- H075

- H076

- H077

- H078

- H079

- H080

- H081

- H082

- H083

- H084

- H085

- H086

- H087

- H088

- H089

- H090

- H091

- H092

- H093

- H094

- H095

- H096

- H097

- H098

- H099

- H100

- H101

- H102

- H103

- H104

- H105

- H106

- H107

- H108

- H109

- H110

- H111

- H112

- H113

- H114

- H115

- H116

- H117

- H118

- H119

- H120

- H121

- H122

- H123

- H124

- H125

- H126

- H127

- H128

- H129

- H130

- H131

- H132

- H133

- H134

- H135

- H136

- H137

- H138

- H139

- H140

- H141

- H142

- H143

- H144

- H145

- H146

- H147

- H148

- H149

- H150

- H151

- H152

- H153

- H154

- H155

- H156

- H157

- H158

- H159

- H160

- H161

- H162

- H163

- H164

- H165

- H166

- H167

- H168

- H169

- H170

- H171

- H172

- H173

- H174

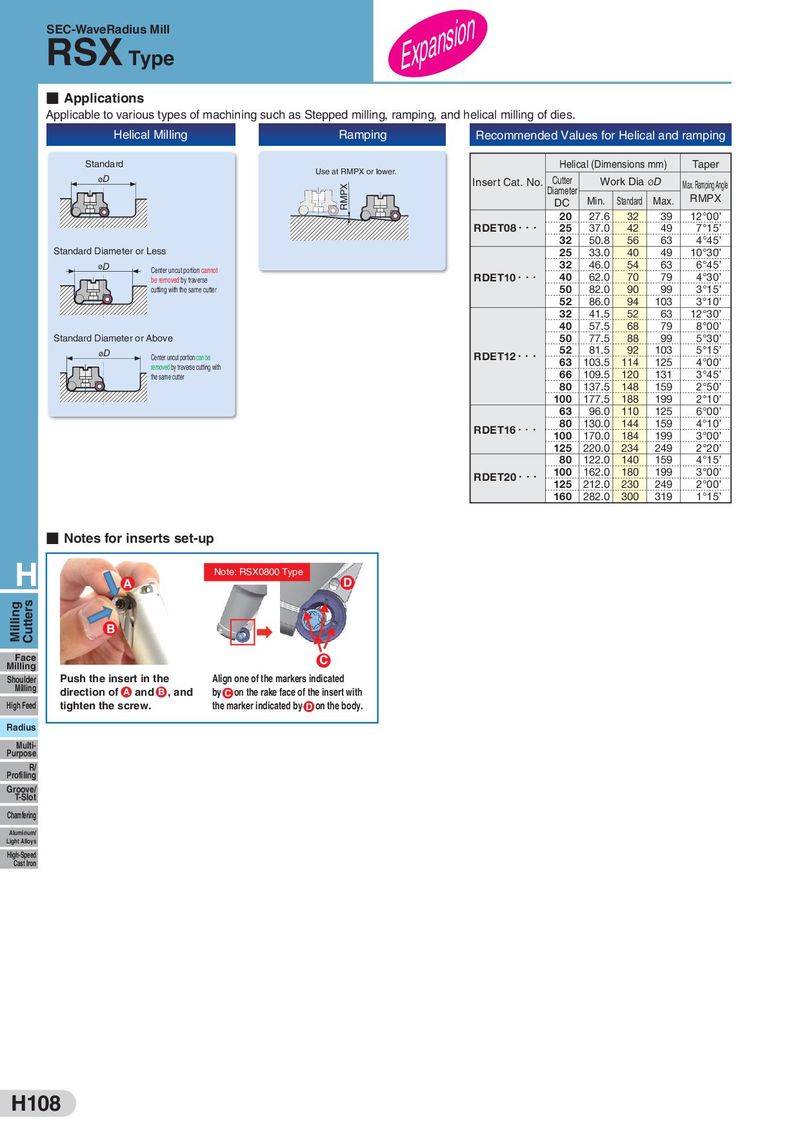

SEC-WaveRadius Mill Expansion RSX Type ■ Applications Applicable to various types of machining such as Stepped milling, ramping, and helical milling of dies. Helical Milling Ramping Recommended Values for Helical and ramping Standard Use at RMPX or lower. Helical (Dimensions mm) Taper øD RMPX Insert Cat. No. Cutter Work Dia øD Max. Ramping Angle Diameter Min. Standard Max. RMPX DC 20 27.6 32 39 12°00’ RDET08・・・ 25 37.0 42 49 7°15’ 32 50.8 56 63 4°45’ Standard Diameter or Less 25 33.0 40 49 10°30’ øD Center uncut portion cannot 32 46.0 54 63 6°45’ be removed by traverse RDET10・・・ 40 62.0 70 79 4°30’ cutting with the same cutter 50 82.0 90 99 3°15’ 52 86.0 94 103 3°10’ 32 41.5 52 63 12°30’ 40 57.5 68 79 8°00’ Standard Diameter or Above 50 77.5 88 99 5°30’ øD RDET12・・・ 52 81.5 92 103 5°15’ Center uncut portion can be 63 103.5 114 125 4°00’ removed by traverse cutting with 66 109.5 120 131 3°45’ the same cutter 80 137.5 148 159 2°50’ 100 177.5 188 199 2°10’ 63 96.0 110 125 6°00’ RDET16・・・ 80 130.0 144 159 4°10’ 100 170.0 184 199 3°00’ 125 220.0 234 249 2°20’ 80 122.0 140 159 4°15’ RDET20・・・ 100 162.0 180 199 3°00’ 125 212.0 230 249 2°00’ 160 282.0 300 319 1°15’ ■ Notes for inserts set-up H Note: RSX0800 Type A D Milling Cutters B Face C Milling Shoulder Push the insert in the Align one of the markers indicated Milling direction of A and B , and by C on the rake face of the insert with High Feed tighten the screw. the marker indicated by D on the body. Radius Multi- Purpose R/ Profiling Groove/ T-Slot Chamfering Aluminum/ Light Alloys High-Speed Cast Iron H108

Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo модульные системы для револьверных головок токарных станков

Каталог Sumitomo модульные системы для револьверных головок токарных станков Каталог Sumitomo токарные резцы (державки) для внутреннего точения

Каталог Sumitomo токарные резцы (державки) для внутреннего точения Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019 Каталог Sumitomo монолитные фрезы

Каталог Sumitomo монолитные фрезы