Каталог Sumitomo фрезы со сменными пластинами - страница 3

Навигация

- H001

- H002

- H003

- H004

- H005

- H006

- H007

- H008

- H009

- H010

- H011

- H012

- H013

- H014

- H015

- H016

- H017

- H018

- H019

- H020

- H021

- H022

- H023

- H024

- H025

- H026

- H027

- H028

- H029

- H030

- H031

- H032

- H033

- H034

- H035

- H036

- H037

- H038

- H039

- H040

- H041

- H042

- H043

- H044

- H045

- H046

- H047

- H048

- H049

- H050

- H051

- H052

- H053

- H054

- H055

- H056

- H057

- H058

- H059

- H060

- H061

- H062

- H063

- H064

- H065

- H066

- H067

- H068

- H069

- H070

- H071

- H072

- H073

- H074

- H075

- H076

- H077

- H078

- H079

- H080

- H081

- H082

- H083

- H084

- H085

- H086

- H087

- H088

- H089

- H090

- H091

- H092

- H093

- H094

- H095

- H096

- H097

- H098

- H099

- H100

- H101

- H102

- H103

- H104

- H105

- H106

- H107

- H108

- H109

- H110

- H111

- H112

- H113

- H114

- H115

- H116

- H117

- H118

- H119

- H120

- H121

- H122

- H123

- H124

- H125

- H126

- H127

- H128

- H129

- H130

- H131

- H132

- H133

- H134

- H135

- H136

- H137

- H138

- H139

- H140

- H141

- H142

- H143

- H144

- H145

- H146

- H147

- H148

- H149

- H150

- H151

- H152

- H153

- H154

- H155

- H156

- H157

- H158

- H159

- H160

- H161

- H162

- H163

- H164

- H165

- H166

- H167

- H168

- H169

- H170

- H171

- H172

- H173

- H174

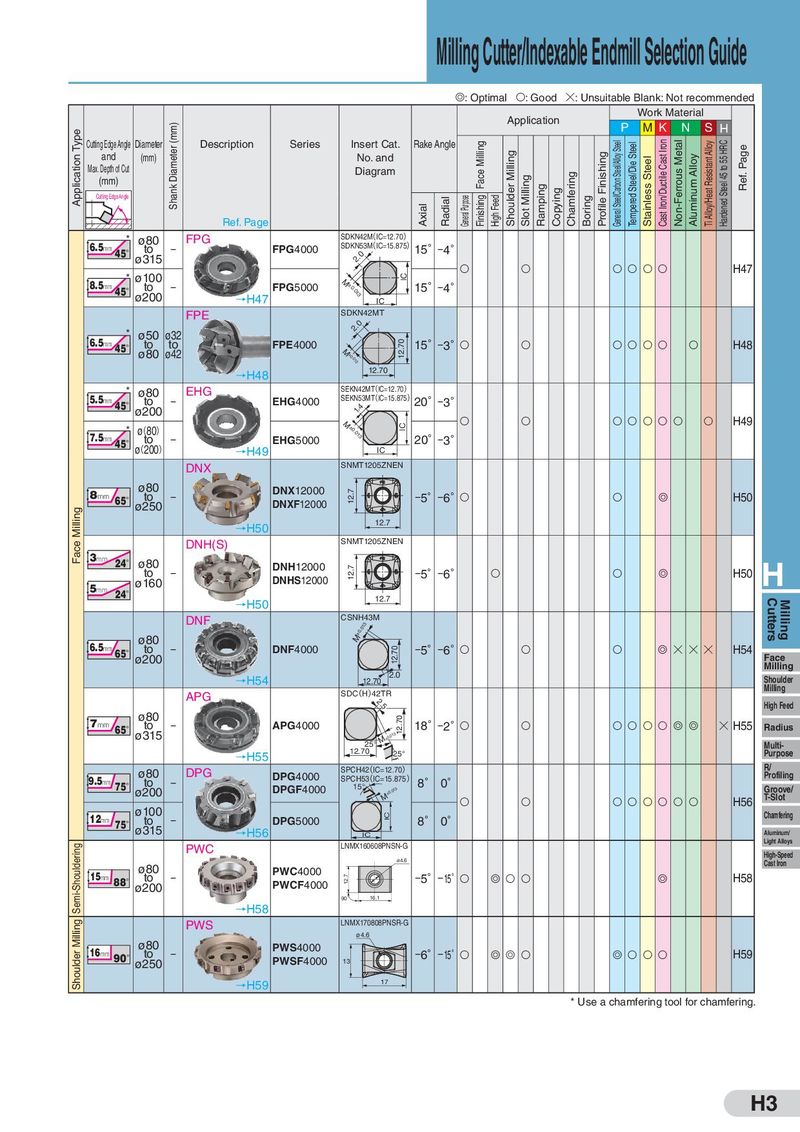

Milling Cutter/Indexable Endmill Selection Guide G: Optimal S: Good H: Unsuitable Blank: Not recommended Application Work Material Application Type Shank Diameter (mm) P MK N S H Cutting Edge Angle Diameter Description Series Insert Cat. Rake Angle Face Milling General Steel/Carbon Steel/Alloy Steel Tempered Steel/Die Steel Cast Iron/Ductile Cast Iron Non-Ferrous Metal Ti Alloy/Heat Resistant Alloy Hardened Steel 45 to 55 HRC Ref. Page and (mm) No. and Shoulder Milling Profile Finishing Stainless Steel Aluminum Alloy Max. Depth of Cut Diagram Chamfering (mm) Slot Milling Ramping Cutting Edge Angle Radial General Purpose Finishing High Feed Copying Boring Ref. Page Axial * ø80 FPG SDKN42M(IC=12.70) 6.5mm 45°ø3to15 − FPG4000 SDKN53M(IC=15.875) 15°−4° 2.0 * ø100 IC S S S S S S H47 8.5mm 45°ø2to00 − FPG5000 M±0.013 15°−4° →H47 IC FPE SDKN42MT * ø50 ø32 2.0 6.5mm 45° to to FPE4000 12.70 15°−3°S S S S S S S H48 ø80 ø42 M ±0.013 →H48 12.70 * ø80 EHG SEKN42MT(IC=12.70) 5.5mm 45°ø2to00 − EHG4000 SEKN53MT(IC=15.875) 20°−3° 1.4 * ø(80) M ±0.013 IC S S S S S S S S H49 7.5mm 45°ø(t2o00) − EHG5000 20°−3° →H49 IC DNX SNMT1205ZNEN 8mm ø80 DNX12000 12.7 65°ø2to50 − −5°−6°S S G H50 DNXF12000 Milling →H50 12.7 Face DNH(S) SNMT1205ZNEN 3mm 24° ø80 DNH12000 H to − DNHS12000 12.7 −5°−6° S S G H50 ø160 5mm 24° →H50 12.7 Cutters Milling DNF CSNH43M ±0.013 ø80 M 6.5mm 65°ø2to00 − DNF4000 12.70 −5°−6°S S S G H H H H54 Face Milling →H54 12.70 2.0 Shoulder APG SDC(H)42TR Milling 2.5 High Feed 7mm ø80 12.70 65°ø3to15 − APG4000 18°−2°S S S S S S G G H H55 Radius 25° M±0.013 Multi- →H55 12.70 25° Purpose ø80 DPG SPCH42(IC=12.70) R/ DPG4000 Profiling 9.5mm 75°ø2to00 − SPCH53(IC=15.875) 8° 0° DPGF4000 15° M±0.013 Groove/ S S S S S S S S H56 T-Slot 12mm ø100 IC Chamfering 75°ø3to15 − DPG5000 8° 0° →H56 IC Aluminum/ Semi-Shouldering PWC LNMX160608PNSN-G Light Alloys ø4.6 High-Speed ø80 PWC4000 Cast Iron 15mm 88°ø2to00 − PWCF4000 12.7 −5°−15° S G S S G H58 90˚ 16.1 →H58 Shoulder Milling PWS LNMX170808PNSR-G ø4.6 16mm ø80 PWS4000 90°ø2to50 − −6°−15° S G G S G S S S H59 PWSF4000 13 →H59 17 * Use a chamfering tool for chamfering. H3

Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo модульные системы для револьверных головок токарных станков

Каталог Sumitomo модульные системы для револьверных головок токарных станков Каталог Sumitomo токарные резцы (державки) для внутреннего точения

Каталог Sumitomo токарные резцы (державки) для внутреннего точения Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019 Каталог Sumitomo монолитные фрезы

Каталог Sumitomo монолитные фрезы