Каталог Sumitomo фрезы со сменными пластинами - страница 2

Навигация

- H001

- H002

- H003

- H004

- H005

- H006

- H007

- H008

- H009

- H010

- H011

- H012

- H013

- H014

- H015

- H016

- H017

- H018

- H019

- H020

- H021

- H022

- H023

- H024

- H025

- H026

- H027

- H028

- H029

- H030

- H031

- H032

- H033

- H034

- H035

- H036

- H037

- H038

- H039

- H040

- H041

- H042

- H043

- H044

- H045

- H046

- H047

- H048

- H049

- H050

- H051

- H052

- H053

- H054

- H055

- H056

- H057

- H058

- H059

- H060

- H061

- H062

- H063

- H064

- H065

- H066

- H067

- H068

- H069

- H070

- H071

- H072

- H073

- H074

- H075

- H076

- H077

- H078

- H079

- H080

- H081

- H082

- H083

- H084

- H085

- H086

- H087

- H088

- H089

- H090

- H091

- H092

- H093

- H094

- H095

- H096

- H097

- H098

- H099

- H100

- H101

- H102

- H103

- H104

- H105

- H106

- H107

- H108

- H109

- H110

- H111

- H112

- H113

- H114

- H115

- H116

- H117

- H118

- H119

- H120

- H121

- H122

- H123

- H124

- H125

- H126

- H127

- H128

- H129

- H130

- H131

- H132

- H133

- H134

- H135

- H136

- H137

- H138

- H139

- H140

- H141

- H142

- H143

- H144

- H145

- H146

- H147

- H148

- H149

- H150

- H151

- H152

- H153

- H154

- H155

- H156

- H157

- H158

- H159

- H160

- H161

- H162

- H163

- H164

- H165

- H166

- H167

- H168

- H169

- H170

- H171

- H172

- H173

- H174

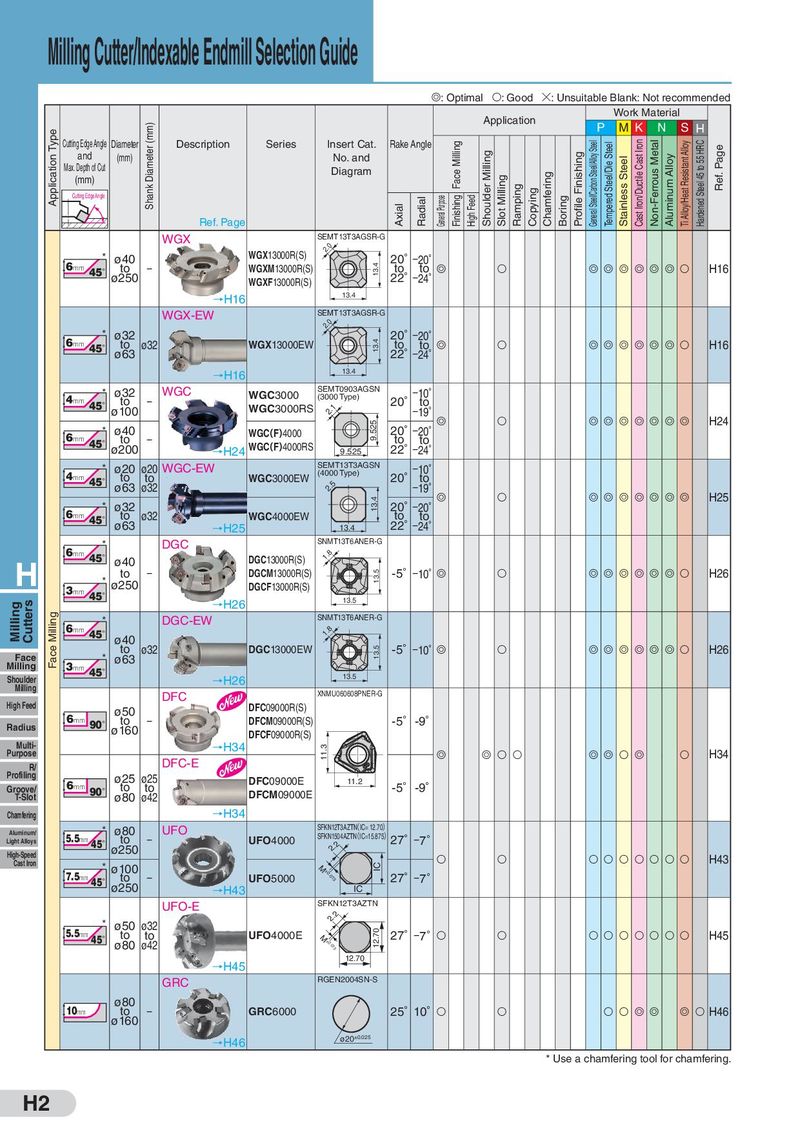

Milling Cutter/Indexable Endmill Selection Guide G: Optimal S: Good H: Unsuitable Blank: Not recommended Application Work Material Application Type Shank Diameter (mm) P MK N S H Cutting Edge Angle Diameter Description Series Insert Cat. Rake Angle Face Milling General Steel/Carbon Steel/Alloy Steel Tempered Steel/Die Steel Cast Iron/Ductile Cast Iron Non-Ferrous Metal Ti Alloy/Heat Resistant Alloy Hardened Steel 45 to 55 HRC Ref. Page and (mm) No. and Shoulder Milling Profile Finishing Stainless Steel Aluminum Alloy Max. Depth of Cut Diagram Chamfering (mm) Slot Milling Ramping Cutting Edge Angle Radial General Purpose Finishing High Feed Copying Boring Ref. Page Axial WGX SEMT13T3AGSR-G * WGX13000R(S) 2.0 6mm ø40 13.4 2t0o°−2to0°G 45°ø2to50 − WGXM13000R(S) S G G G G G G S H16 22°−24° WGXF13000R(S) →H16 13.4 WGX-EW SEMT13T3AGSR-G * 2.0 6mm ø32 13.4 20°−20° to ø32 WGX13000EW to to G S G G G G G G S H16 45° ø63 22°−24° →H16 13.4 * ø32 WGC WGC3000 SEMT0903AGSN −10° 4mm 45°ø1to00 − (3000 Type) 20° to WGC3000RS 2.1 −19° 9.525 G S G G G G G G G H24 * ø40 2t0o°−2to0° 6mm 45°ø2to00 − WGC(F)4000 →H24 WGC(F)4000RS 9.525 22°−24° * ø20 ø20 WGC-EW SEMT13T3AGSN −10° 4mm to to WGC3000EW (4000 Type) 20° to 45° ø63 ø32 2.5 −19° * 13.4 G S G G G G G G G H25 ø32 2t0o°−2to0° 6mm to ø32 WGC4000EW 45° ø63 →H25 13.4 22°−24° * DGC SNMT13T6ANER-G 6mm 45° ø40 DGC13000R(S) 1.8 H to − DGCM13000R(S) 13.5 -5°−10°G S G G G G G G S H26 * ø250 3mm DGCF13000R(S) 45° Milling Cutters →H26 13.5 Face Milling * DGC-EW SNMT13T6ANER-G 6mm 45° ø40 1.8 Face * to ø32 DGC13000EW 13.5 -5°−10°G S G G G G G G S H26 ø63 Milling 3mm 45° Shoulder →H26 13.5 Milling DFC XNMU060608PNER-G High Feed ø50 DFC09000R(S) Radius 6mm 90°ø1to60 − DFCM09000R(S) -5°-9° DFCF09000R(S) Multi- →H34 11.3 H34 Purpose G G S S G G S G S DFC-E R/ Profiling ø25 ø25 DFC09000E 11.2 6mm to to -5°-9° Groove/ 90° DFCM09000E T-Slot ø80 ø42 Chamfering →H34 Aluminum/ * ø80 UFO SFKN12T3AZTN(IC= 12.70) Light Alloys 5.5mm 45°ø2to50 − UFO4000 SFKN1504AZTN(IC=15.875) 27°−7° High-Speed 2.2 Cast Iron * ø100 IC S S S S S S S S S H43 7.5mm 45°ø2to50 M ±0.013 − UFO5000 27°−7° →H43 IC UFO-E SFKN12T3AZTN * ø50 ø32 2.2 5.5mm 45° to to UFO4000E M 12.70 27°−7°S S S S S S S S S H45 ø80 ø42 ±0.013 →H45 12.70 GRC RGEN2004SN-S 10mm ø80 to − GRC6000 25°10°S S S S G G G S H46 ø160 →H46 ø20±0.025 * Use a chamfering tool for chamfering. H2

Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo модульные системы для револьверных головок токарных станков

Каталог Sumitomo модульные системы для револьверных головок токарных станков Каталог Sumitomo токарные резцы (державки) для внутреннего точения

Каталог Sumitomo токарные резцы (державки) для внутреннего точения Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019 Каталог Sumitomo монолитные фрезы

Каталог Sumitomo монолитные фрезы