Каталог Sumitomo фрезы со сменными пластинами - страница 63

Навигация

- H001

- H002

- H003

- H004

- H005

- H006

- H007

- H008

- H009

- H010

- H011

- H012

- H013

- H014

- H015

- H016

- H017

- H018

- H019

- H020

- H021

- H022

- H023

- H024

- H025

- H026

- H027

- H028

- H029

- H030

- H031

- H032

- H033

- H034

- H035

- H036

- H037

- H038

- H039

- H040

- H041

- H042

- H043

- H044

- H045

- H046

- H047

- H048

- H049

- H050

- H051

- H052

- H053

- H054

- H055

- H056

- H057

- H058

- H059

- H060

- H061

- H062

- H063

- H064

- H065

- H066

- H067

- H068

- H069

- H070

- H071

- H072

- H073

- H074

- H075

- H076

- H077

- H078

- H079

- H080

- H081

- H082

- H083

- H084

- H085

- H086

- H087

- H088

- H089

- H090

- H091

- H092

- H093

- H094

- H095

- H096

- H097

- H098

- H099

- H100

- H101

- H102

- H103

- H104

- H105

- H106

- H107

- H108

- H109

- H110

- H111

- H112

- H113

- H114

- H115

- H116

- H117

- H118

- H119

- H120

- H121

- H122

- H123

- H124

- H125

- H126

- H127

- H128

- H129

- H130

- H131

- H132

- H133

- H134

- H135

- H136

- H137

- H138

- H139

- H140

- H141

- H142

- H143

- H144

- H145

- H146

- H147

- H148

- H149

- H150

- H151

- H152

- H153

- H154

- H155

- H156

- H157

- H158

- H159

- H160

- H161

- H162

- H163

- H164

- H165

- H166

- H167

- H168

- H169

- H170

- H171

- H172

- H173

- H174

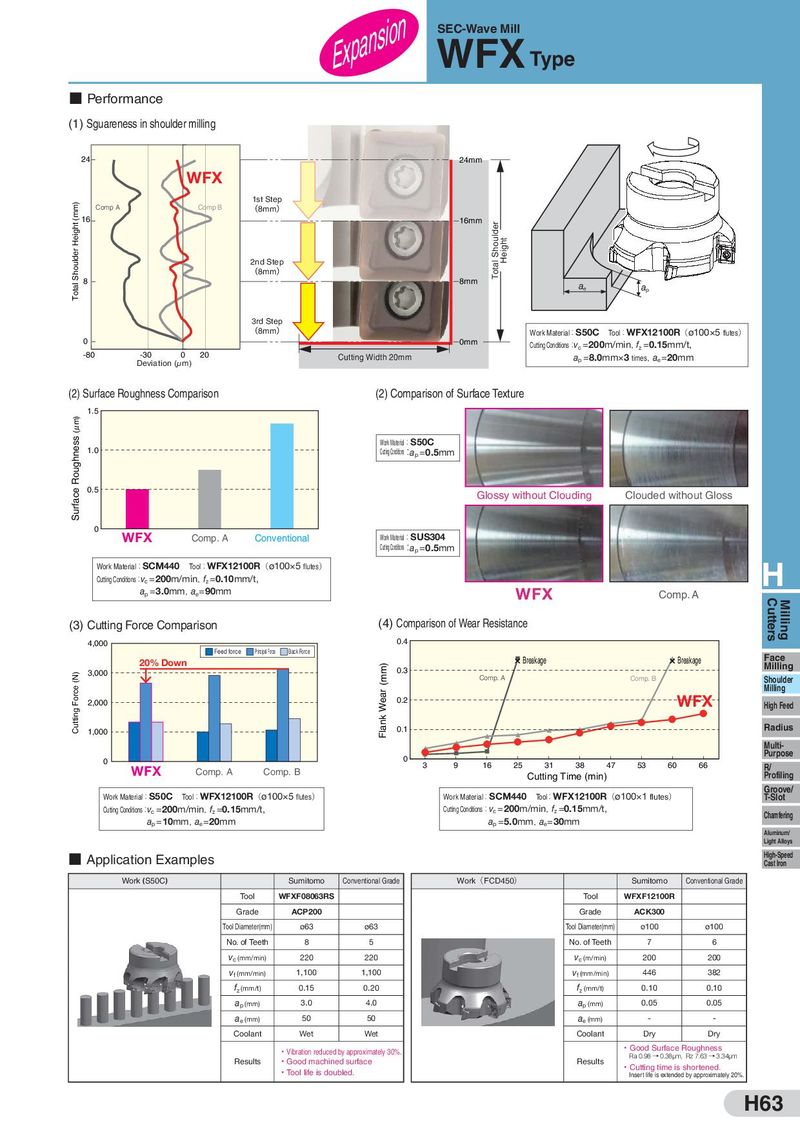

Expansion SEC-Wave Mill WFX Type ■ Performance (1) Sguareness in shoulder milling 24 24mm WFX (mm) 1st Step Comp A Comp B (8mm) Shoulder Height 16 16mm Total Shoulder 2nd Step Height (8mm) Total 8 8mm ae ap 3rd Step (8mm) Work Material:S50C Tool:WFX12100R(ø100×5 flutes) 0 0mm Cutting Conditions:vc =200m/min, fz =0.15mm/t, -80 -30 0 20 Cutting Width 20mm ap =8.0mm×3 times, ae=20mm Deviation (µm) (2) Surface Roughness Comparison (2) Comparison of Surface Texture 1.5 Surface Roughness (䃛m) Work Materia:l S50C 1.0 CutingConditions:ap =0.5mm 0.5 Glossy without Clouding Clouded without Gloss 0 WFX Comp. A Conventional Work Materia:l SUS304 CutingConditions:ap =0.5mm Work Material:SCM440 Tool:WFX12100R(ø100×5 flutes) H Cutting Conditions:vc =200m/min, fz =0.10mm/t, ap =3.0mm, ae=90mm WFX Comp. A (3) Cutting Force Comparison (4) Comparison of Wear Resistance Cutters Milling 4,000 0.4 Feed force Principal Force Back Force Face 20% Down Flank Wear (mm) Breakage Breakage Milling Cutting Force (N) 3,000 0.3 Comp. A Comp. B Shoulder Milling 2,000 0.2 WFX High Feed 1,000 0.1 Radius Multi- Purpose 0 0 3 9 16 25 31 38 47 53 60 66 R/ WFX Comp. A Comp. B Profiling Cutting Time (min) Work Material:S50C Tool:WFX12100R(ø100×5 flutes) Work Material:SCM440 Tool:WFX12100R(ø100×1 flutes) Groove/ T-Slot Cutting Conditions:vc =200m/min, fz =0.15mm/t, Cutting Conditions:vc =200m/min, fz =0.15mm/t, Chamfering ap =10mm, ae=20mm ap =5.0mm, ae=30mm Aluminum/ Light Alloys ■ Application Examples High-Speed Cast Iron Work (S50C) Sumitomo Conventional Grade Work(FCD450) Sumitomo Conventional Grade Tool WFXF08063RS Tool WFXF12100R Grade ACP200 Grade ACK300 Tool Diameter(mm) ø63 ø63 Tool Diameter(mm) ø100 ø100 No. of Teeth 8 5 No. of Teeth 7 6 vc (mm/min) 220 220 vc (m/min) 200 200 vf (mm/min) 1,100 1,100 vf (mm/min) 446 382 fz (mm/t) 0.15 0.20 fz (mm/t) 0.10 0.10 ap (mm) 3.0 4.0 ap (mm) 0.05 0.05 ae (mm) 50 50 ae (mm) - - Coolant Wet Wet Coolant Dry Dry ・Vibration reduced by approximately 30%. ・Good Surface Roughness Results ・Good machined surface Results Ra 0.98 → 0.38μm, Rz 7.63 → 3.34μm ・Tool life is doubled. ・Cutting time is shortened. Insert life is extended by approximately 20%. H63

Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo модульные системы для револьверных головок токарных станков

Каталог Sumitomo модульные системы для револьверных головок токарных станков Каталог Sumitomo токарные резцы (державки) для внутреннего точения

Каталог Sumitomo токарные резцы (державки) для внутреннего точения Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019 Каталог Sumitomo монолитные фрезы

Каталог Sumitomo монолитные фрезы