Каталог Sumitomo фрезы со сменными пластинами - страница 18

Навигация

- H001

- H002

- H003

- H004

- H005

- H006

- H007

- H008

- H009

- H010

- H011

- H012

- H013

- H014

- H015

- H016

- H017

- H018

- H019

- H020

- H021

- H022

- H023

- H024

- H025

- H026

- H027

- H028

- H029

- H030

- H031

- H032

- H033

- H034

- H035

- H036

- H037

- H038

- H039

- H040

- H041

- H042

- H043

- H044

- H045

- H046

- H047

- H048

- H049

- H050

- H051

- H052

- H053

- H054

- H055

- H056

- H057

- H058

- H059

- H060

- H061

- H062

- H063

- H064

- H065

- H066

- H067

- H068

- H069

- H070

- H071

- H072

- H073

- H074

- H075

- H076

- H077

- H078

- H079

- H080

- H081

- H082

- H083

- H084

- H085

- H086

- H087

- H088

- H089

- H090

- H091

- H092

- H093

- H094

- H095

- H096

- H097

- H098

- H099

- H100

- H101

- H102

- H103

- H104

- H105

- H106

- H107

- H108

- H109

- H110

- H111

- H112

- H113

- H114

- H115

- H116

- H117

- H118

- H119

- H120

- H121

- H122

- H123

- H124

- H125

- H126

- H127

- H128

- H129

- H130

- H131

- H132

- H133

- H134

- H135

- H136

- H137

- H138

- H139

- H140

- H141

- H142

- H143

- H144

- H145

- H146

- H147

- H148

- H149

- H150

- H151

- H152

- H153

- H154

- H155

- H156

- H157

- H158

- H159

- H160

- H161

- H162

- H163

- H164

- H165

- H166

- H167

- H168

- H169

- H170

- H171

- H172

- H173

- H174

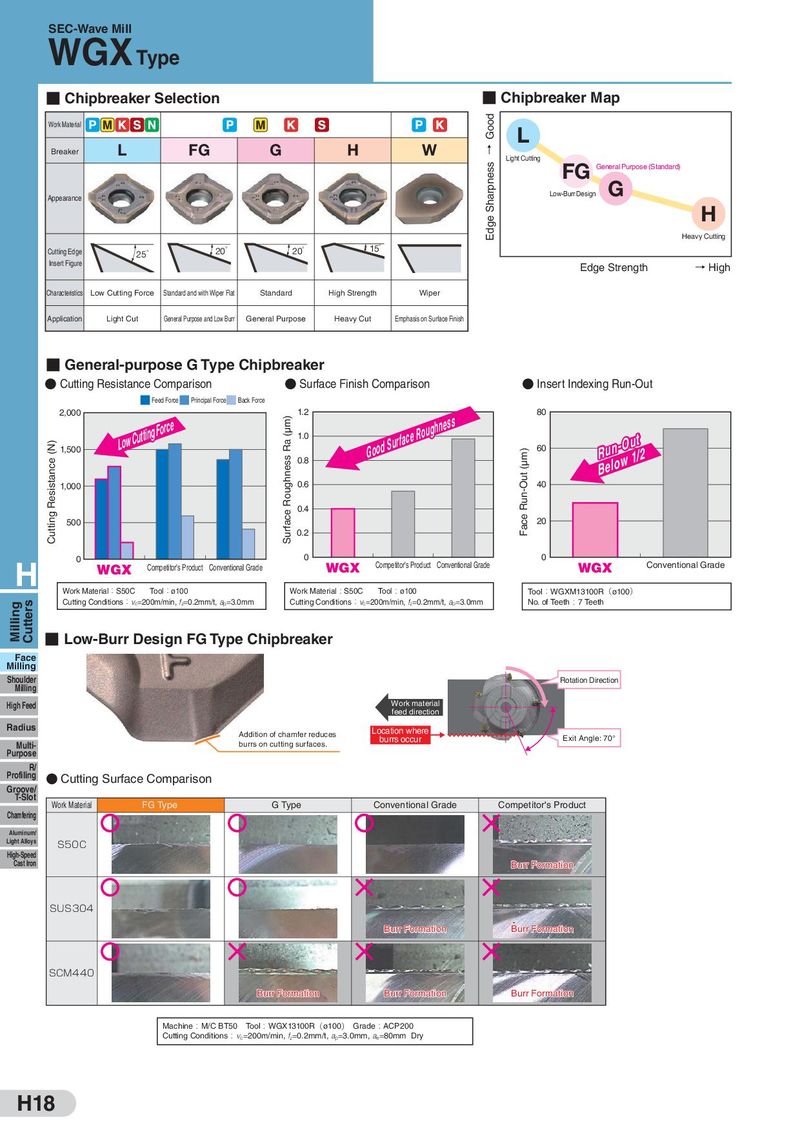

SEC-Wave Mill WGX Type ■ Chipbreaker Selection ■ Chipbreaker Map Work Material Good L Breaker L FG G H W ↑ Light Cutting Edge Sharpness FG General Purpose (Standard) Appearance Low-Burr Design G H Heavy Cutting Cutting Edge 25゚ 20゚ 20゚ 15゚ Insert Figure Edge Strength → High Characteristics Low Cutting Force Standard and with Wiper Flat Standard High Strength Wiper Application Light Cut General Purpose and Low Burr General Purpose Heavy Cut Emphasis on Surface Finish ■ General-purpose G Type Chipbreaker ● Cutting Resistance Comparison ● Surface Finish Comparison ● Insert Indexing Run-Out Feed Force Principal Force Back Force 2,000 (μm) 1.2 Good Surface Roughness 80 Cutting Resistance (N) Low Cutting Force Surface Roughness Ra 1.0 BRuelno-wOu1t/2 1,500 Face Run-Out (μm) 60 0.8 1,000 0.6 40 0.4 500 20 0.2 0 0 Competitor's Product Conventional Grade 0 Conventional Grade H WGX Competitor's Product Conventional Grade WGX WGX Work Material:S50C Tool:ø100 Work Material:S50C Tool:ø100 Tool:WGXM13100R(ø100) Milling Cutters Cutting Conditions:vc=200m/min, fz=0.2mm/t, ap=3.0mm Cutting Conditions:vc=200m/min, fz=0.2mm/t, ap=3.0mm No. of Teeth:7 Teeth ■ Low-Burr Design FG Type Chipbreaker Face Milling Shoulder Rotation Direction Milling High Feed Work material feed direction Radius Addition of chamfer reduces Location where Multi- burrs on cutting surfaces. burrs occur Exit Angle: 70° Purpose R/ Profiling ● Cutting Surface Comparison Groove/ T-Slot Work Material FG Type G Type Conventional Grade Competitor's Product Chamfering Aluminum/ Light Alloys S50C High-Speed Cast Iron Burr Formation SUS304 Burr Formation Burr Formation SCM440 Burr Formation Burr Formation Burr Formation Machine:M/C BT50 Tool:WGX13100R(ø100) Grade:ACP200 Cutting Conditions:vc=200m/min, fz=0.2mm/t, ap=3.0mm, ae=80mm Dry H18

Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo модульные системы для револьверных головок токарных станков

Каталог Sumitomo модульные системы для револьверных головок токарных станков Каталог Sumitomo токарные резцы (державки) для внутреннего точения

Каталог Sumitomo токарные резцы (державки) для внутреннего точения Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019 Каталог Sumitomo монолитные фрезы

Каталог Sumitomo монолитные фрезы