Каталог Sumitomo фрезы со сменными пластинами - страница 28

Навигация

- H001

- H002

- H003

- H004

- H005

- H006

- H007

- H008

- H009

- H010

- H011

- H012

- H013

- H014

- H015

- H016

- H017

- H018

- H019

- H020

- H021

- H022

- H023

- H024

- H025

- H026

- H027

- H028

- H029

- H030

- H031

- H032

- H033

- H034

- H035

- H036

- H037

- H038

- H039

- H040

- H041

- H042

- H043

- H044

- H045

- H046

- H047

- H048

- H049

- H050

- H051

- H052

- H053

- H054

- H055

- H056

- H057

- H058

- H059

- H060

- H061

- H062

- H063

- H064

- H065

- H066

- H067

- H068

- H069

- H070

- H071

- H072

- H073

- H074

- H075

- H076

- H077

- H078

- H079

- H080

- H081

- H082

- H083

- H084

- H085

- H086

- H087

- H088

- H089

- H090

- H091

- H092

- H093

- H094

- H095

- H096

- H097

- H098

- H099

- H100

- H101

- H102

- H103

- H104

- H105

- H106

- H107

- H108

- H109

- H110

- H111

- H112

- H113

- H114

- H115

- H116

- H117

- H118

- H119

- H120

- H121

- H122

- H123

- H124

- H125

- H126

- H127

- H128

- H129

- H130

- H131

- H132

- H133

- H134

- H135

- H136

- H137

- H138

- H139

- H140

- H141

- H142

- H143

- H144

- H145

- H146

- H147

- H148

- H149

- H150

- H151

- H152

- H153

- H154

- H155

- H156

- H157

- H158

- H159

- H160

- H161

- H162

- H163

- H164

- H165

- H166

- H167

- H168

- H169

- H170

- H171

- H172

- H173

- H174

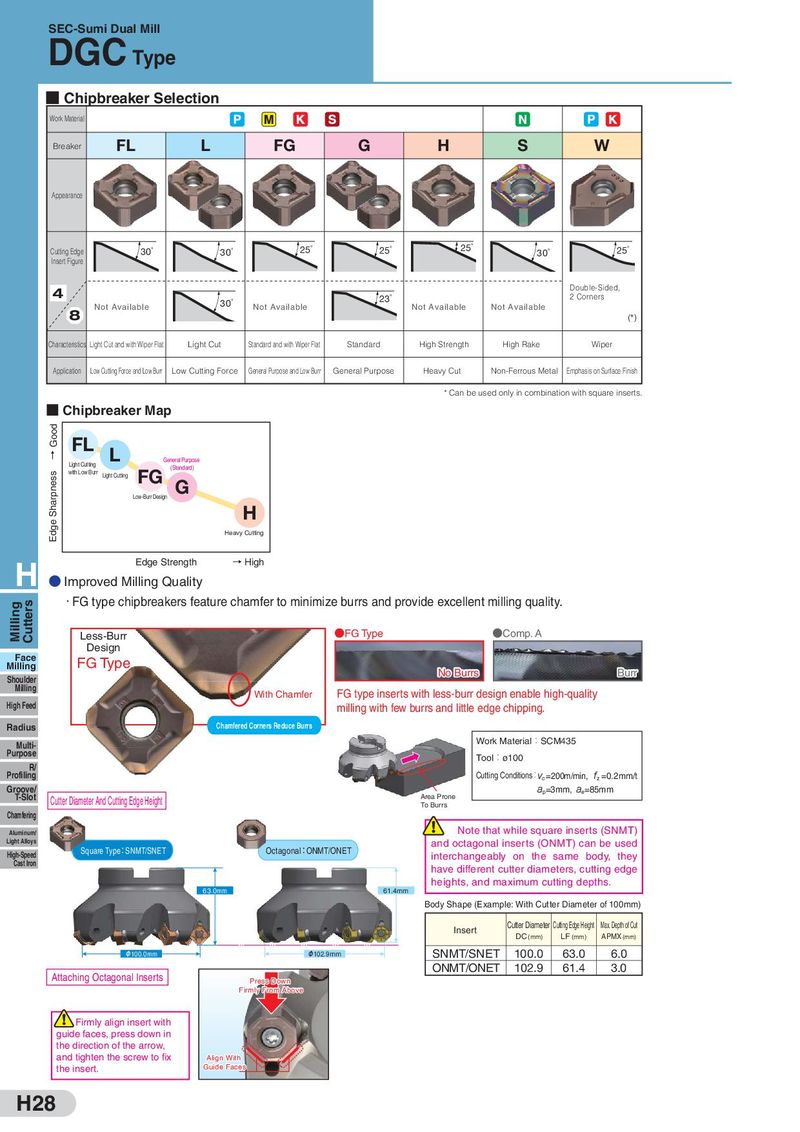

SEC-Sumi Dual Mill DGC カッタ径:φ Type mm〜φ mm カッタ径:φ mm〜φ mm カッタ径:φ mm〜φ mm カッタ径:φ mm〜φ mm 刃数: 枚刃〜 枚刃 刃数: 枚刃〜 枚刃 刃数: 枚刃〜 枚刃 刃数: 枚刃〜 枚刃 取付け:インチ/メトリック対応 取付け:インチ/メトリック対応 取付け:インチ/メトリック対応 取付け:メトリック対応 ■ Chipbreaker Selection Work Material Breaker FL L FG G H S W Appearance 標準ピッチ ファインピッチ エクストラファインピッチ エンドミルタイプ Cutting Edge 30゚ 30゚ 25゚ 25゚ 25゚ 30゚ 25゚ Insert Figure 4 Double-Sided, 30゚ 23゚ 2 Corners 8 Not Available Not Available Not Available Not Available (*) Characteristics Light Cut and with Wiper Flat Light Cut Standard and with Wiper Flat Standard High Strength High Rake Wiper Application Low Cutting Force and Low Burr Low Cutting Force General Purpose and Low Burr General Purpose Heavy Cut Non-Ferrous Metal Emphasis on Surface Finish * Can be used only in combination with square inserts. ■ Chipbreaker Map Good FL ↑ L General Purpose Light Cutting (Standard) Edge Sharpness with Low Burr Light Cutting FG Low-Burr Design G H Heavy Cutting H Edge Strength → High ● Improved Milling Quality Milling Cutters ・FG type chipbreakers feature chamfer to minimize burrs and provide excellent milling quality. Less-Burr ●FG Type ●Comp. A Design Face FG Type Milling No Burrs Burr Shoulder Milling With Chamfer FG type inserts with less-burr design enable high-quality High Feed milling with few burrs and little edge chipping. Radius Chamfered Corners Reduce Burrs Multi- Work Material:SCM435 Purpose Tool:ø100 R/ Cutting Conditions: Profiling c =200m/min, z =0.2mm/t Groove/ Area Prone p=3mm, e=85mm T-Slot Cutter Diameter And Cutting Edge Height To Burrs Chamfering Aluminum/ Note that while square inserts (SNMT) Light Alloys and octagonal inserts (ONMT) can be used High-Speed Square Type:SNMT/SNET Octagonal:ONMT/ONET interchangeably on the same body, they Cast Iron have different cutter diameters, cutting edge heights, and maximum cutting depths. 63.0mm 61.4mm Body Shape (Example: With Cutter Diameter of 100mm) Insert Cutter Diameter Cutting Edge Height Max. Depth of Cut DC (mm) LF (mm) APMX (mm) φ100.0mm φ102.9mm SNMT/SNET 100.0 63.0 6.0 Attaching Octagonal Inserts ONMT/ONET 102.9 61.4 3.0 Press Down Firmly From Above Firmly align insert with guide faces, press down in the direction of the arrow, and tighten the screw to fix Align With the insert. Guide Faces H28

Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo модульные системы для револьверных головок токарных станков

Каталог Sumitomo модульные системы для револьверных головок токарных станков Каталог Sumitomo токарные резцы (державки) для внутреннего точения

Каталог Sumitomo токарные резцы (державки) для внутреннего точения Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019 Каталог Sumitomo монолитные фрезы

Каталог Sumitomo монолитные фрезы