Каталог Sumitomo фрезы со сменными пластинами - страница 43

Навигация

- H001

- H002

- H003

- H004

- H005

- H006

- H007

- H008

- H009

- H010

- H011

- H012

- H013

- H014

- H015

- H016

- H017

- H018

- H019

- H020

- H021

- H022

- H023

- H024

- H025

- H026

- H027

- H028

- H029

- H030

- H031

- H032

- H033

- H034

- H035

- H036

- H037

- H038

- H039

- H040

- H041

- H042

- H043

- H044

- H045

- H046

- H047

- H048

- H049

- H050

- H051

- H052

- H053

- H054

- H055

- H056

- H057

- H058

- H059

- H060

- H061

- H062

- H063

- H064

- H065

- H066

- H067

- H068

- H069

- H070

- H071

- H072

- H073

- H074

- H075

- H076

- H077

- H078

- H079

- H080

- H081

- H082

- H083

- H084

- H085

- H086

- H087

- H088

- H089

- H090

- H091

- H092

- H093

- H094

- H095

- H096

- H097

- H098

- H099

- H100

- H101

- H102

- H103

- H104

- H105

- H106

- H107

- H108

- H109

- H110

- H111

- H112

- H113

- H114

- H115

- H116

- H117

- H118

- H119

- H120

- H121

- H122

- H123

- H124

- H125

- H126

- H127

- H128

- H129

- H130

- H131

- H132

- H133

- H134

- H135

- H136

- H137

- H138

- H139

- H140

- H141

- H142

- H143

- H144

- H145

- H146

- H147

- H148

- H149

- H150

- H151

- H152

- H153

- H154

- H155

- H156

- H157

- H158

- H159

- H160

- H161

- H162

- H163

- H164

- H165

- H166

- H167

- H168

- H169

- H170

- H171

- H172

- H173

- H174

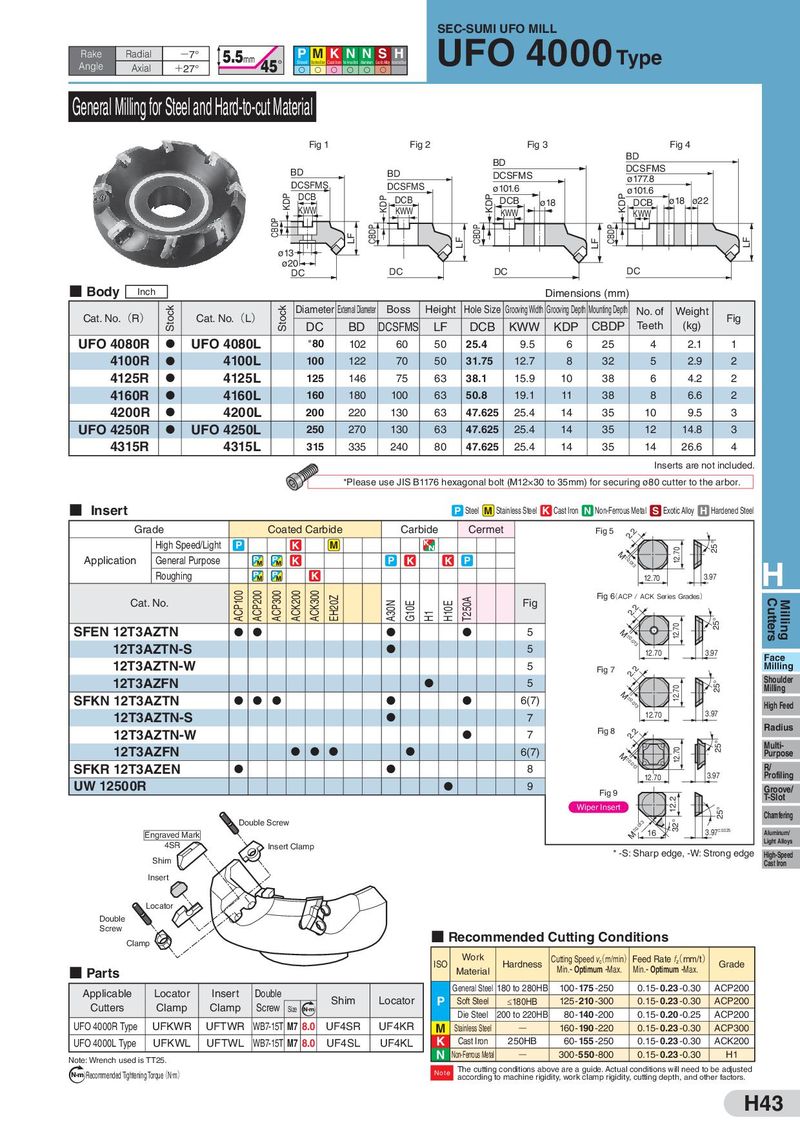

SEC-SUMI UFO MILL Rake Radial −7° 5.5mm P MK N N SH UFO 40 0 0 Type Angle Axial 45° Steel Stainless Steel Cast Iron Non-Ferrous Metal Aluminum Exotic Alloy Hardened Steel +27° S S S S S S General Milling for Steel and Hard-to-cut Material Fig 1 Fig 2 Fig 3 Fig 4 BD BD BD BD DCSFMS DCSFMS DCSFMS DCSFMS ø177.8 KDP DCB ø101.6 KDP ø101.6 KDP DCB KDP DCB ø18 DCB ø18 ø22 KWW KWW KWW KWW CBDP LF CBDP CBDP CBDP LF LF LF ø13 ø20 DC DC DC DC ■ Body Inch Dimensions (mm) Cat. No.(R) Stock Cat. No.(L) Stock Diameter External Diameter Boss Height Hole Size Grooving Width Grooving Depth Mounting Depth No. of Weight Fig DC BD DCSFMS LF DCB KWW KDP CBDP Teeth (kg) UFO 4080R D UFO 4080L *80 102 60 50 25.4 9.5 6 25 4 2.1 1 4100R D 4100L 100 122 70 50 31.75 12.7 8 32 5 2.9 2 4125R D 4125L 125 146 75 63 38.1 15.9 10 38 6 4.2 2 4160R D 4160L 160 180 100 63 50.8 19.1 11 38 8 6.6 2 4200R D 4200L 200 220 130 63 47.625 25.4 14 35 10 9.5 3 UFO 4250R D UFO 4250L 250 270 130 63 47.625 25.4 14 35 12 14.8 3 4315R 4315L 315 335 240 80 47.625 25.4 14 35 14 26.6 4 Inserts are not included. *Please use JIS B1176 hexagonal bolt (M12×30 to 35mm) for securing ø80 cutter to the arbor. ■ Insert P Steel M Stainless Steel K Cast Iron N Non-Ferrous Metal S Exotic Alloy H Hardened Steel Grade Coated Carbide Carbide Cermet Fig 5 2.2 High Speed/Light P K M 12.70 25° Application General Purpose K P K K P M ±0.013 Roughing K 12.70 3.97 H Cat. No. ACP100 ACP200 ACP300 ACK200 ACK300 EH20Z A30N G10E H10E T250A Fig Fig 6(ACP / ACK Series Grades) Cutters Milling H1 2.2 SFEN 12T3AZTN D D D D 5 12.70 25° M ±0.013 12T3AZTN-S D 5 12.70 3.97 Face 12T3AZTN-W 5 Fig 7 2.2 Milling 12T3AZFN D 5 25° Shoulder Milling 12.70 SFKN 12T3AZTN D D D D D 6(7) M ±0.013 3.97 High Feed 12T3AZTN-S D 7 12.70 12T3AZTN-W D 7 Fig 8 2.2 Radius 12T3AZFN D D D D 6(7) 12.70 25° Multi- Purpose M ±0.013 SFKR 12T3AZEN D D 8 R/ Profiling 12.70 3.97 UW 12500R D 9 Fig 9 Groove/ 12.2 T-Slot Wiper Insert 25° Double Screw 32° Chamfering Engraved Mark ±0.013 M 16 3.97±0.025 Aluminum/ 4SR Insert Clamp Light Alloys Shim * -S: Sharp edge, -W: Strong edge High-Speed Cast Iron Insert Locator Double Screw ■ Recommended Cutting Conditions Clamp ISO Work Hardness Cutting Speed v(c m/min) Feed Rate f(z mm/t) Grade ■ Parts Material Min.- Optimum -Max. Min.- Optimum -Max. Applicable Locator Insert Double General Steel 180 to 280HB 100- 175 -250 0.15- 0.23 -0.30 ACP200 Cutters Clamp Clamp Screw Size Shim Locator P Soft Steel ≤180HB 125- 210 -300 0.15- 0.23 -0.30 ACP200 Nm Die Steel 200 to 220HB 80- 140 -200 0.15- 0.20 -0.25 ACP200 UFO 4000R Type UFKWR UFTWR WB7-15T M7 8.0 UF4SR UF4KR M Stainless Steel Q 160- 190 -220 0.15- 0.23 -0.30 ACP300 UFO 4000L Type UFKWL UFTWL WB7-15T M7 8.0 UF4SL UF4KL K Cast Iron 250HB 60- 155 -250 0.15- 0.23 -0.30 ACK200 Note: Wrench used is TT25. N Non-Ferrous Metal Q 300- 550 -800 0.15- 0.23 -0.30 H1 N m Recommended Tightening Torque(N・m) Note The cutting conditions above are a guide. Actual conditions will need to be adjusted according to machine rigidity, work clamp rigidity, cutting depth, and other factors. H43

Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo модульные системы для револьверных головок токарных станков

Каталог Sumitomo модульные системы для револьверных головок токарных станков Каталог Sumitomo токарные резцы (державки) для внутреннего точения

Каталог Sumitomo токарные резцы (державки) для внутреннего точения Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019 Каталог Sumitomo монолитные фрезы

Каталог Sumitomo монолитные фрезы