Каталог Sumitomo фрезы со сменными пластинами - страница 123

Навигация

- H001

- H002

- H003

- H004

- H005

- H006

- H007

- H008

- H009

- H010

- H011

- H012

- H013

- H014

- H015

- H016

- H017

- H018

- H019

- H020

- H021

- H022

- H023

- H024

- H025

- H026

- H027

- H028

- H029

- H030

- H031

- H032

- H033

- H034

- H035

- H036

- H037

- H038

- H039

- H040

- H041

- H042

- H043

- H044

- H045

- H046

- H047

- H048

- H049

- H050

- H051

- H052

- H053

- H054

- H055

- H056

- H057

- H058

- H059

- H060

- H061

- H062

- H063

- H064

- H065

- H066

- H067

- H068

- H069

- H070

- H071

- H072

- H073

- H074

- H075

- H076

- H077

- H078

- H079

- H080

- H081

- H082

- H083

- H084

- H085

- H086

- H087

- H088

- H089

- H090

- H091

- H092

- H093

- H094

- H095

- H096

- H097

- H098

- H099

- H100

- H101

- H102

- H103

- H104

- H105

- H106

- H107

- H108

- H109

- H110

- H111

- H112

- H113

- H114

- H115

- H116

- H117

- H118

- H119

- H120

- H121

- H122

- H123

- H124

- H125

- H126

- H127

- H128

- H129

- H130

- H131

- H132

- H133

- H134

- H135

- H136

- H137

- H138

- H139

- H140

- H141

- H142

- H143

- H144

- H145

- H146

- H147

- H148

- H149

- H150

- H151

- H152

- H153

- H154

- H155

- H156

- H157

- H158

- H159

- H160

- H161

- H162

- H163

- H164

- H165

- H166

- H167

- H168

- H169

- H170

- H171

- H172

- H173

- H174

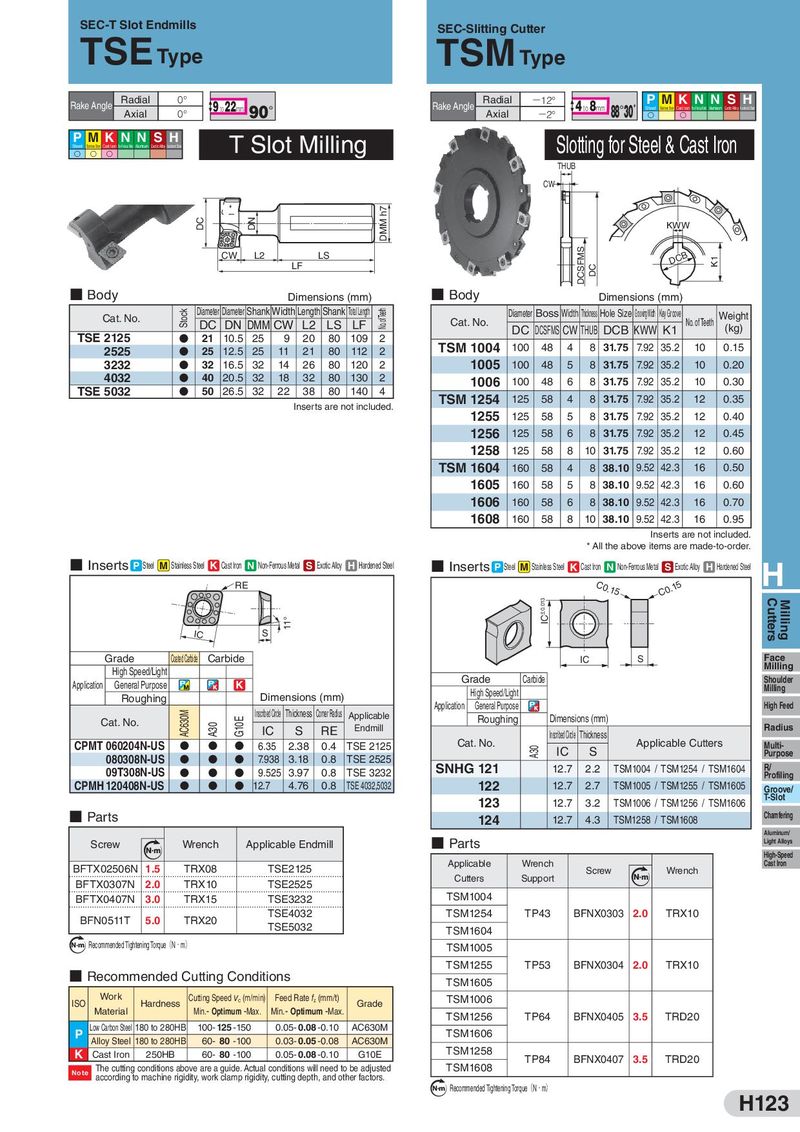

SEC-T Slot Endmills SEC-Slitting Cutter TSE Type TSM Type Rake Angle Radial 0° 9 to 22mm Rake Angle Radial −12° 4 to 8mm 88°30 P M K N N S H Axial 0° 90° Axial Steel Stainless Steel Cast Iron Non-Ferrous Metal Aluminum Exotic Alloy Hardened Steel −2° S S P M K N N SH T Slot Milling Slotting for Steel & Cast Iron Steel Stainless Steel Cast Iron Non-Ferrous Metal Aluminum Exotic Alloy Hardened Steel S S S THUB CW DC DN DMM h7 KWW CW L2 LS DCSFMS DCB K1 LF DC ■ Body Dimensions (mm) ■ Body Dimensions (mm) Cat. No. Stock Diameter Diameter Shank Width Length Shank Total Length No.ofTeeth Diameter Boss Width Thickness Hole Size GroovingWidth Key Groove Weight DC DN DMM CW L2 LS LF Cat. No. DC DCSFMS CW THUB DCB KWW K1 No. of Teeth (kg) TSE 2125 D 21 10.5 25 9 20 80 109 2 TSM 1004 100 48 4 8 31.75 7.92 35.2 10 0.15 2525 D 25 12.5 25 11 21 80 112 2 3232 D 32 16.5 32 14 26 80 120 2 1005 100 48 5 8 31.75 7.92 35.2 10 0.20 4032 D 40 20.5 32 18 32 80 130 2 1006 100 48 6 8 31.75 7.92 35.2 10 0.30 TSE 5032 D 50 26.5 32 22 38 80 140 4 TSM 1254 125 58 4 8 31.75 7.92 35.2 12 0.35 Inserts are not included. 1255 125 58 5 8 31.75 7.92 35.2 12 0.40 1256 125 58 6 8 31.75 7.92 35.2 12 0.45 1258 125 58 8 10 31.75 7.92 35.2 12 0.60 TSM 1604 160 58 4 8 38.10 9.52 42.3 16 0.50 1605 160 58 5 8 38.10 9.52 42.3 16 0.60 1606 160 58 6 8 38.10 9.52 42.3 16 0.70 1608 160 58 8 10 38.10 9.52 42.3 16 0.95 Inserts are not included. * All the above items are made-to-order. ■ Inserts P Steel M Stainless Steel K Cast Iron N Non-Ferrous Metal S Exotic Alloy H Hardened Steel ■ Inserts P Steel M Stainless Steel K Cast Iron N Non-Ferrous Metal S Exotic Alloy H Hardened Steel H RE C0.15 C0.15 11° IC±0.013 Cutters Milling IC S Grade Coated Carbide Carbide IC S Face Milling High Speed/Light Grade Carbide Shoulder Application General Purpose K Milling High Speed/Light Roughing Dimensions (mm) Application General Purpose High Feed AC630M InscribedCircle Thickness Corner Radius Cat. No. G10E Applicable Roughing Dimensions (mm) A30 IC S RE Endmill InscribedCircle Thickness Radius CPMT 060204N-US D D D 6.35 2.38 0.4 TSE 2125 Cat. No. A30 IC S Applicable Cutters Multi- 080308N-US D D D 7.938 3.18 0.8 TSE 2525 Purpose 09T308N-US D D D 9.525 3.97 0.8 TSE 3232 SNHG 121 12.7 2.2 TSM1004 / TSM1254 / TSM1604 R/ Profiling CPMH 120408N-US D D D 12.7 4.76 0.8 TSE 4032,5032 122 12.7 2.7 TSM1005 / TSM1255 / TSM1605 Groove/ 123 12.7 3.2 TSM1006 / TSM1256 / TSM1606 T-Slot ■ Parts 124 12.7 4.3 TSM1258 / TSM1608 Chamfering Aluminum/ Screw Wrench Applicable Endmill ■ Parts Light Alloys Nm High-Speed BFTX02506N 1.5 TRX08 TSE2125 Applicable Wrench Screw Wrench Cast Iron BFTX0307N 2.0 TRX10 TSE2525 Cutters Support Nm BFTX0407N 3.0 TRX15 TSE3232 TSM1004 BFN0511T 5.0 TRX20 TSE4032 TSM1254 TP43 BFNX0303 2.0 TRX10 TSE5032 TSM1604 N m Recommended Tightening Torque(N・m) TSM1005 TSM1255 TP53 BFNX0304 2.0 TRX10 ■ Recommended Cutting Conditions TSM1605 ISO Work Hardness Cutting Speed c (m/min) Feed Rate fz (mm/t) Grade TSM1006 Material Min.- Optimum -Max. Min.- Optimum -Max. TSM1256 TP64 BFNX0405 3.5 TRD20 P Low Carbon Steel 180 to 280HB 100- 125 -150 0.05- 0.08 -0.10 AC630M TSM1606 Alloy Steel 180 to 280HB 60- 80 -100 0.03- 0.05 -0.08 AC630M K Cast Iron 250HB 60- 80 -100 0.05- 0.08 -0.10 G10E TSM1258 TP84 BFNX0407 3.5 TRD20 Note The cutting conditions above are a guide. Actual conditions will need to be adjusted TSM1608 according to machine rigidity, work clamp rigidity, cutting depth, and other factors. N m Recommended Tightening Torque(N・m) H123

Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo модульные системы для револьверных головок токарных станков

Каталог Sumitomo модульные системы для револьверных головок токарных станков Каталог Sumitomo токарные резцы (державки) для внутреннего точения

Каталог Sumitomo токарные резцы (державки) для внутреннего точения Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019 Каталог Sumitomo монолитные фрезы

Каталог Sumitomo монолитные фрезы