Каталог Sumitomo фрезы со сменными пластинами - страница 107

Навигация

- H001

- H002

- H003

- H004

- H005

- H006

- H007

- H008

- H009

- H010

- H011

- H012

- H013

- H014

- H015

- H016

- H017

- H018

- H019

- H020

- H021

- H022

- H023

- H024

- H025

- H026

- H027

- H028

- H029

- H030

- H031

- H032

- H033

- H034

- H035

- H036

- H037

- H038

- H039

- H040

- H041

- H042

- H043

- H044

- H045

- H046

- H047

- H048

- H049

- H050

- H051

- H052

- H053

- H054

- H055

- H056

- H057

- H058

- H059

- H060

- H061

- H062

- H063

- H064

- H065

- H066

- H067

- H068

- H069

- H070

- H071

- H072

- H073

- H074

- H075

- H076

- H077

- H078

- H079

- H080

- H081

- H082

- H083

- H084

- H085

- H086

- H087

- H088

- H089

- H090

- H091

- H092

- H093

- H094

- H095

- H096

- H097

- H098

- H099

- H100

- H101

- H102

- H103

- H104

- H105

- H106

- H107

- H108

- H109

- H110

- H111

- H112

- H113

- H114

- H115

- H116

- H117

- H118

- H119

- H120

- H121

- H122

- H123

- H124

- H125

- H126

- H127

- H128

- H129

- H130

- H131

- H132

- H133

- H134

- H135

- H136

- H137

- H138

- H139

- H140

- H141

- H142

- H143

- H144

- H145

- H146

- H147

- H148

- H149

- H150

- H151

- H152

- H153

- H154

- H155

- H156

- H157

- H158

- H159

- H160

- H161

- H162

- H163

- H164

- H165

- H166

- H167

- H168

- H169

- H170

- H171

- H172

- H173

- H174

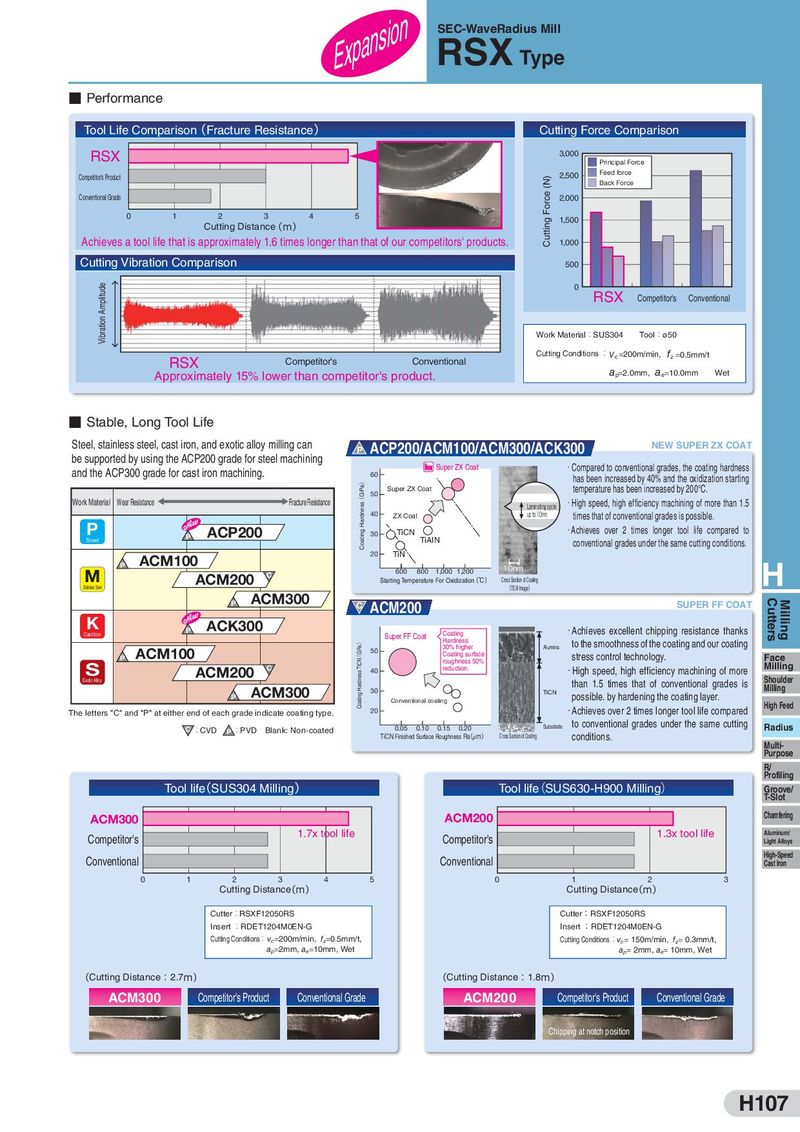

Expansion SEC-WaveRadius Mill RSX Type ■ Performance Tool Life Comparison(Fracture Resistance) Cutting Force Comparison RSX 3,000 Principal Force Competitor's Product Cutting Force (N) 2,500 Feed force Back Force Conventional Grade 2,000 0 1 2 3 4 5 1,500 Cutting Distance(m) Achieves a tool life that is approximately 1.6 times longer than that of our competitors' products. 1,000 Cutting Vibration Comparison 500 Vibration Amplitude 0 RSX Competitor's Conventional Work Material:SUS304 Tool:ø50 RSX Competitor's Conventional Cutting Conditions :Vc =200m/min, fz =0.5mm/t Approximately 15% lower than competitor's product. ap=2.0mm, ae=10.0mm Wet ■ Stable, Long Tool Life Steel, stainless steel, cast iron, and exotic alloy milling can P ACP200/ACM100/ACM300/ACK300 NEW SUPER ZX COAT be supported by using the ACP200 grade for steel machining Super ZX Coat ・Compared to conventional grades, the coating hardness and the ACP300 grade for cast iron machining. 60 has been increased by 40% and the oxidization starting Coating Hardness(GPa) 50 Super ZX Coat temperature has been increased by 200°C. Work Material Wear Resistance Fracture Resistance Laminating cycle ・High speed, high efficiency machining of more than 1.5 40 ZX Coat up to 10nm times that of conventional grades is possible. P P ACP200 30 TiCN ・Achieves over 2 times longer tool life compared to Steel TiAIN conventional grades under the same cutting conditions. ACM100 20 TiN P 10nm H M ACM200 C 600 800 1,000 1,200 Starting Temperature For Oxidization(℃) Cross Section of Coating Stainless Steel (TEM Image) P ACM300 C ACM200 SUPER FF COAT Cutters Milling K P ACK300 Coating ・Achieves excellent chipping resistance thanks Cast Iron Super FF Coat Coating Hardness TiCN(GPa) Hardness: to the smoothness of the coating and our coating ACM100 50 30% higher Alumina P Coating surface stress control technology. Face S roughness 50% Milling ACM200 C 40 reduction. ・High speed, high efficiency machining of more Exotic Alloy than 1.5 times that of conventional grades is Shoulder ACM300 30 TiCN possible. by hardening the coating layer. Milling P Conventional coating The letters "C" and "P" at either end of each grade indicate coating type. 20 ・Achieves over 2 times longer tool life compared High Feed C :CVD P :PVD Blank: Non-coated 0.05 0.10 0.15 0.20 Substrate to conventional grades under the same cutting Radius TiCN Finished Surface Roughness Ra(μm) Cross Section of Coating conditions. Multi- Purpose R/ Profiling Tool life(SUS304 Milling) Tool life(SUS630-H900 Milling) Groove/ T-Slot ACM300 ACM200 Chamfering Competitor's 1.7x tool life Competitor's 1.3x tool life Aluminum/ Light Alloys Conventional Conventional High-Speed Cast Iron 0 1 2 3 4 5 0 1 2 3 Cutting Distance(m) Cutting Distance(m) Cutter:RSXF12050RS Cutter:RSXF12050RS Insert :RDET1204M0EN-G Insert :RDET1204M0EN-G Cutting Conditions: vc=200m/min, fz=0.5mm/t, Cutting Conditions:vc= 150m/min, fz= 0.3mm/t, ap=2mm, ae=10mm, Wet ap= 2mm, ae= 10mm, Wet (Cutting Distance:2.7m) (Cutting Distance:1.8m) ACM300 Competitor's Product Conventional Grade ACM200 Competitor's Product Conventional Grade Chipping at notch position H107

Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo модульные системы для револьверных головок токарных станков

Каталог Sumitomo модульные системы для револьверных головок токарных станков Каталог Sumitomo токарные резцы (державки) для внутреннего точения

Каталог Sumitomo токарные резцы (державки) для внутреннего точения Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019 Каталог Sumitomo монолитные фрезы

Каталог Sumitomo монолитные фрезы