Каталог Sumitomo фрезы со сменными пластинами - страница 105

Навигация

- H001

- H002

- H003

- H004

- H005

- H006

- H007

- H008

- H009

- H010

- H011

- H012

- H013

- H014

- H015

- H016

- H017

- H018

- H019

- H020

- H021

- H022

- H023

- H024

- H025

- H026

- H027

- H028

- H029

- H030

- H031

- H032

- H033

- H034

- H035

- H036

- H037

- H038

- H039

- H040

- H041

- H042

- H043

- H044

- H045

- H046

- H047

- H048

- H049

- H050

- H051

- H052

- H053

- H054

- H055

- H056

- H057

- H058

- H059

- H060

- H061

- H062

- H063

- H064

- H065

- H066

- H067

- H068

- H069

- H070

- H071

- H072

- H073

- H074

- H075

- H076

- H077

- H078

- H079

- H080

- H081

- H082

- H083

- H084

- H085

- H086

- H087

- H088

- H089

- H090

- H091

- H092

- H093

- H094

- H095

- H096

- H097

- H098

- H099

- H100

- H101

- H102

- H103

- H104

- H105

- H106

- H107

- H108

- H109

- H110

- H111

- H112

- H113

- H114

- H115

- H116

- H117

- H118

- H119

- H120

- H121

- H122

- H123

- H124

- H125

- H126

- H127

- H128

- H129

- H130

- H131

- H132

- H133

- H134

- H135

- H136

- H137

- H138

- H139

- H140

- H141

- H142

- H143

- H144

- H145

- H146

- H147

- H148

- H149

- H150

- H151

- H152

- H153

- H154

- H155

- H156

- H157

- H158

- H159

- H160

- H161

- H162

- H163

- H164

- H165

- H166

- H167

- H168

- H169

- H170

- H171

- H172

- H173

- H174

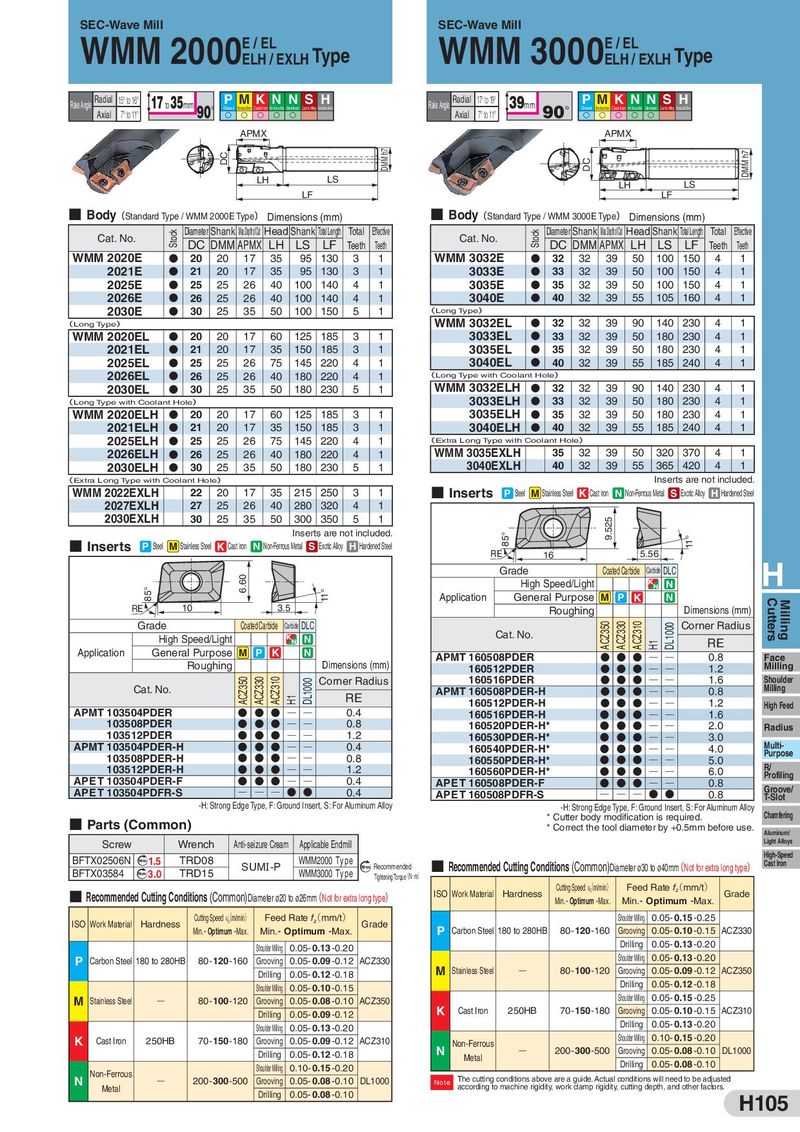

SEC-Wave Mill SEC-Wave Mill WMM 2000E / EL Type WMM 3000E / EL Type ELH / EXLH ELH / EXLH RakeAngle Radial 15° to 16° 17 to 35mm 90° P MK N N SH RakeAngle Radial 17° to 19° 39mm P MKN N SH 90° Steel Axial Steel Stainless Steel Cast Iron Non-Ferrous Metal Aluminum Exotic Alloy Hardened Steel Axial 7° to 11° Stainless Steel Cast Iron Non-Ferrous Metal Aluminum Exotic Alloy Hardened Steel 7° to 11° S S S S S S S S S S APMX APMX DC DMM h7 DC DMM h7 LH LS LH LS LF LF ■ Body(Standard Type / WMM 2000E Type) Dimensions (mm) ■ Body(Standard Type / WMM 3000E Type) Dimensions (mm) Cat. No. Stock Diameter Shank Max.DepthofCut Head Shank Total Length Total Effective Cat. No. Stock Diameter Shank Max.DepthofCut Head Shank Total Length Total Effective DC DMM APMX LH LS LF Teeth Teeth DC DMM APMX LH LS LF Teeth Teeth WMM 2020E D 20 20 17 35 95 130 3 1 WMM 3032E D 32 32 39 50 100 150 4 1 2021E D 21 20 17 35 95 130 3 1 3033E D 33 32 39 50 100 150 4 1 2025E D 25 25 26 40 100 140 4 1 3035E D 35 32 39 50 100 150 4 1 2026E D 26 25 26 40 100 140 4 1 3040E D 40 32 39 55 105 160 4 1 2030E D 30 25 35 50 100 150 5 1 (Long Type) (Long Type) WMM 3032EL D 32 32 39 90 140 230 4 1 WMM 2020EL D 20 20 17 60 125 185 3 1 3033EL D 33 32 39 50 180 230 4 1 2021EL D 21 20 17 35 150 185 3 1 3035EL D 35 32 39 50 180 230 4 1 2025EL D 25 25 26 75 145 220 4 1 3040EL D 40 32 39 55 185 240 4 1 2026EL D 26 25 26 40 180 220 4 1 (Long Type with Coolant Hole) 2030EL D 30 25 35 50 180 230 5 1 WMM 3032ELH D 32 32 39 90 140 230 4 1 (Long Type with Coolant Hole) 3033ELH D 33 32 39 50 180 230 4 1 WMM 2020ELH D 20 20 17 60 125 185 3 1 3035ELH D 35 32 39 50 180 230 4 1 2021ELH D 21 20 17 35 150 185 3 1 3040ELH D 40 32 39 55 185 240 4 1 2025ELH D 25 25 26 75 145 220 4 1 (Extra Long Type with Coolant Hole) 2026ELH D 26 25 26 40 180 220 4 1 WMM 3035EXLH 35 32 39 50 320 370 4 1 2030ELH D 30 25 35 50 180 230 5 1 3040EXLH 40 32 39 55 365 420 4 1 (Extra Long Type with Coolant Hole) Inserts are not included. WMM 2022EXLH 22 20 17 35 215 250 3 1 ■ Inserts P Steel M Stainless Steel K Cast Iron N Non-Ferrous Metal S Exotic Alloy H Hardened Steel 2027EXLH 27 25 26 40 280 320 4 1 2030EXLH 30 25 35 50 300 350 5 1 9.525 Inserts are not included. 85° 11° ■ Inserts P Steel M Stainless Steel K Cast Iron N Non-Ferrous Metal S Exotic Alloy H Hardened Steel RE 16 5.56 6.60 Grade Coated Carbide Carbide DLC H 85° 11° High Speed/Light N Application General Purpose M P K N Cutters Milling RE 10 3.5 Roughing Dimensions (mm) Grade Coated Carbide Carbide DLC Cat. No. ACZ350 ACZ330 ACZ310 DL1000 Corner Radius High Speed/Light N H1 RE Application General Purpose M P K N APMT 160508PDER D D D Q Q 0.8 Face Roughing Dimensions (mm) 160512PDER D D D Q Q 1.2 Milling ACZ350 ACZ330 ACZ310 DL1000 Corner Radius 160516PDER D D D Q Q 1.6 Shoulder Milling Cat. No. APMT 160508PDER-H D D D Q Q 0.8 H1 RE 160512PDER-H D D D Q Q 1.2 High Feed APMT 103504PDER 0.4 D D D Q Q 160516PDER-H D D D Q Q 1.6 103508PDER D D D Q Q 0.8 160520PDER-H* D D D Q Q 2.0 Radius 103512PDER D D D Q Q 1.2 160530PDER-H* D D D Q Q 3.0 APMT 103504PDER-H D D D Q Q 0.4 160540PDER-H* D D D Q Q 4.0 Multi- Purpose 103508PDER-H D D D Q Q 0.8 160550PDER-H* D D D Q Q 5.0 R/ 103512PDER-H D D D Q Q 1.2 160560PDER-H* D D D Q Q 6.0 Profiling APET 103504PDER-F D D D Q Q 0.4 APET 160508PDER-F D D D Q Q 0.8 Groove/ APET 103504PDFR-S Q Q Q D D 0.4 APET 160508PDFR-S Q Q Q D D 0.8 T-Slot -H: Strong Edge Type, F: Ground Insert, S: For Aluminum Alloy -H: Strong Edge Type, F: Ground Insert, S: For Aluminum Alloy ■ Parts (Common) * Cutter body modification is required. Chamfering * Correct the tool diameter by +0.5mm before use. Aluminum/ Screw Wrench Anti-seizure Cream Applicable Endmill Light Alloys BFTX02506N N m 1.5 TRD08 WMM2000 Type High-Speed SUMⅠ-P N m Recommended ■ Recommended Cutting Conditions (Common)Diameter ø30 to ø40mm(Not for extra long type) Cast Iron BFTX03584 N m 3.0 TRD15 WMM3000 Type Tightening Torque(N・m) ■ Recommended Cutting Conditions (Common)Diameter ø20 to ø26mm(Not for extra long type) ISO Work Material Hardness Cutting Speed v(c m/min) Feed Rate f(z mm/t) Grade Min.- Optimum -Max. Min.- Optimum -Max. ISO Work Material Hardness Cutting Speed v(c m/min) Feed Rate f(z mm/t) Grade Shoulder Miling 0.05- 0.15 -0.25 Min.- Optimum -Max. Min.- Optimum -Max. P Carbon Steel 180 to 280HB 80- 120 -160 Grooving 0.05- 0.10 -0.15 ACZ330 Shoulder Miling 0.05- 0.13 -0.20 Drilling 0.05- 0.13 -0.20 P Carbon Steel 180 to 280HB 80- 120 -160 Grooving 0.05- 0.09 -0.12 ACZ330 Shoulder Miling 0.05- 0.13 -0.20 Drilling 0.05- 0.12 -0.18 M Stainless Steel Q 80- 100 -120 Grooving 0.05- 0.09 -0.12 ACZ350 Shoulder Miling 0.05- 0.10 -0.15 Drilling 0.05- 0.12 -0.18 M Stainless Steel Q 80- 100 -120 Grooving 0.05- 0.08 -0.10 ACZ350 Shoulder Miling 0.05- 0.15 -0.25 Drilling 0.05- 0.09 -0.12 K Cast Iron 250HB 70- 150 -180 Grooving 0.05- 0.10 -0.15 ACZ310 Shoulder Miling 0.05- 0.13 -0.20 Drilling 0.05- 0.13 -0.20 K Cast Iron 250HB 70- 150 -180 Grooving 0.05- 0.09 -0.12 ACZ310 Non-Ferrous Shoulder Miling 0.10- 0.15 -0.20 Drilling 0.05- 0.12 -0.18 N Metal Q 200- 300 -500 Grooving 0.05- 0.08 -0.10 DL1000 Shoulder Miling 0.10- 0.15 -0.20 Drilling 0.05- 0.08 -0.10 N Non-Ferrous Q 200- 300 -500 Grooving 0.05- 0.08 -0.10 DL1000 The cutting conditions above are a guide. Actual conditions will need to be adjusted Metal Note according to machine rigidity, work clamp rigidity, cutting depth, and other factors. Drilling 0.05- 0.08 -0.10 H105

Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo модульные системы для револьверных головок токарных станков

Каталог Sumitomo модульные системы для револьверных головок токарных станков Каталог Sumitomo токарные резцы (державки) для внутреннего точения

Каталог Sumitomo токарные резцы (державки) для внутреннего точения Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019 Каталог Sumitomo монолитные фрезы

Каталог Sumitomo монолитные фрезы