Каталог Sumitomo фрезы со сменными пластинами - страница 86

Навигация

- H001

- H002

- H003

- H004

- H005

- H006

- H007

- H008

- H009

- H010

- H011

- H012

- H013

- H014

- H015

- H016

- H017

- H018

- H019

- H020

- H021

- H022

- H023

- H024

- H025

- H026

- H027

- H028

- H029

- H030

- H031

- H032

- H033

- H034

- H035

- H036

- H037

- H038

- H039

- H040

- H041

- H042

- H043

- H044

- H045

- H046

- H047

- H048

- H049

- H050

- H051

- H052

- H053

- H054

- H055

- H056

- H057

- H058

- H059

- H060

- H061

- H062

- H063

- H064

- H065

- H066

- H067

- H068

- H069

- H070

- H071

- H072

- H073

- H074

- H075

- H076

- H077

- H078

- H079

- H080

- H081

- H082

- H083

- H084

- H085

- H086

- H087

- H088

- H089

- H090

- H091

- H092

- H093

- H094

- H095

- H096

- H097

- H098

- H099

- H100

- H101

- H102

- H103

- H104

- H105

- H106

- H107

- H108

- H109

- H110

- H111

- H112

- H113

- H114

- H115

- H116

- H117

- H118

- H119

- H120

- H121

- H122

- H123

- H124

- H125

- H126

- H127

- H128

- H129

- H130

- H131

- H132

- H133

- H134

- H135

- H136

- H137

- H138

- H139

- H140

- H141

- H142

- H143

- H144

- H145

- H146

- H147

- H148

- H149

- H150

- H151

- H152

- H153

- H154

- H155

- H156

- H157

- H158

- H159

- H160

- H161

- H162

- H163

- H164

- H165

- H166

- H167

- H168

- H169

- H170

- H171

- H172

- H173

- H174

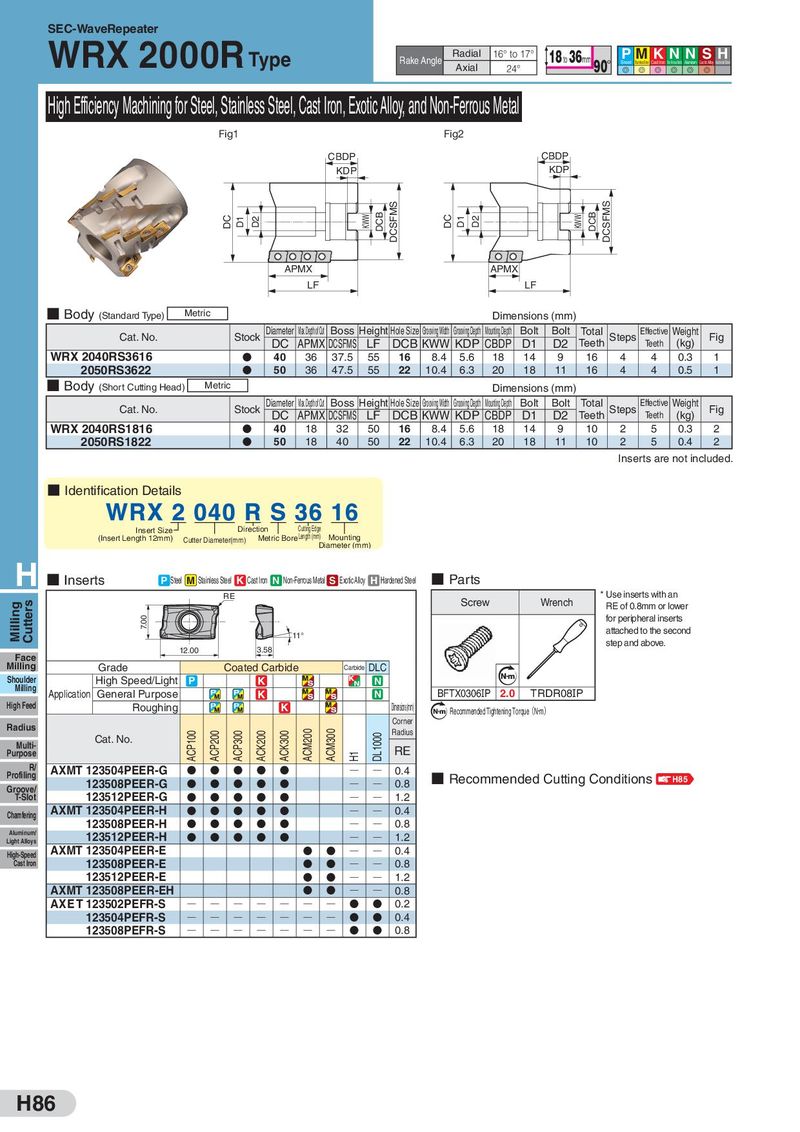

SEC-WaveRepeater WRX 2000R Type Rake Angle Radial 16° to 17° 18 to 36mm P MKN N SH Axial 24° 90°Steel Stainless Steel Cast Iron Non-Ferrous Metal Aluminum Exotic Alloy Hardened Steel G G G G G G High Efficiency Machining for Steel, Stainless Steel, Cast Iron, Exotic Aloy, and Non-Ferrous Metal Fig1 Fig2 CBDP CBDP KDP KDP DC D1 D2 KWW DCB DCSFMS DC D1 D2 KWW DCB DCSFMS APMX APMX LF LF ■ Body (Standard Type) Metric Dimensions (mm) Cat. No. Stock Diameter Max.DepthofCut Boss Height Hole Size Grooving Width Grooving Depth Mounting Depth Bolt Bolt Total Steps Effective Weight Fig DC APMX DCSFMS LF DCB KWW KDP CBDP D1 D2 Teeth Teeth (kg) WRX 2040RS3616 D 40 36 37.5 55 16 8.4 5.6 18 14 9 16 4 4 0.3 1 2050RS3622 D 50 36 47.5 55 22 10.4 6.3 20 18 11 16 4 4 0.5 1 ■ Body (Short Cutting Head) Metric Dimensions (mm) Cat. No. Stock Diameter Max.DepthofCut Boss Height Hole Size Grooving Width Grooving Depth Mounting Depth Bolt Bolt Total Steps Effective Weight Fig DC APMX DCSFMS LF DCB KWW KDP CBDP D1 D2 Teeth Teeth (kg) WRX 2040RS1816 D 40 18 32 50 16 8.4 5.6 18 14 9 10 2 5 0.3 2 2050RS1822 D 50 18 40 50 22 10.4 6.3 20 18 11 10 2 5 0.4 2 Inserts are not included. ■ Identification Details Insert Size Direction Cutting Edge (Insert Length 12mm) Cutter Diameter(mm) Metric BoreLength (mm) Mounting Diameter (mm) H ■ Inserts P Steel M Stainless Steel K Cast Iron N Non-Ferrous Metal S Exotic Alloy H Hardened Steel ■ Parts RE Screw Wrench * Use inserts with an Milling Cutters RE of 0.8mm or lower 7.00 for peripheral inserts 11° attached to the second 3.58 step and above. Face 12.00 Milling Grade Coated Carbide Carbide DLC Shoulder High Speed/Light P K N Nm Milling Application General Purpose K N BFTX0306IP 2.0 TRDR08IP High Feed Roughing K Dimensions (mm) N m Recommended Tightening Torque(N・m) Radius Corner Cat. No. ACP100 ACP200 ACP300 ACK200 ACK300 ACM200 ACM300 DL1000 Radius Multi- RE Purpose H1 R/ AXMT 123504PEER-G D D D D D Q Q 0.4 Profiling 123508PEER-G D D D D D Q Q 0.8 ■ Recommended Cutting Conditions H85 Groove/ 123512PEER-G D D D D D Q Q 1.2 T-Slot Chamfering AXMT 123504PEER-H D D D D D Q Q 0.4 123508PEER-H D D D D D Q Q 0.8 Aluminum/ 123512PEER-H D D D D D Q Q 1.2 Light Alloys High-Speed AXMT 123504PEER-E D D Q Q 0.4 Cast Iron 123508PEER-E D D Q Q 0.8 123512PEER-E D D Q Q 1.2 AXMT 123508PEER-EH D D Q Q 0.8 AXET 123502PEFR-S Q Q Q Q Q Q Q D D 0.2 123504PEFR-S Q Q Q Q Q Q Q D D 0.4 123508PEFR-S Q Q Q Q Q Q Q D D 0.8 H86

Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo модульные системы для револьверных головок токарных станков

Каталог Sumitomo модульные системы для револьверных головок токарных станков Каталог Sumitomo токарные резцы (державки) для внутреннего точения

Каталог Sumitomo токарные резцы (державки) для внутреннего точения Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019 Каталог Sumitomo монолитные фрезы

Каталог Sumitomo монолитные фрезы