Каталог Sumitomo сверла и развертки - страница 97

Навигация

- J001

- J1-001

- J1-002

- J1-003

- J1-004

- J1-005

- J1-006

- J1-007

- J1-008

- J1-009

- J1-010

- J1-011

- J1-012

- J1-013

- J1-014

- J1-015

- J1-016

- J1-017

- J1-018

- J1-019

- J1-020

- J1-021

- J1-022

- J002

- J003

- J004

- J005

- J006

- J007

- J008

- J009

- J010

- J011

- J012

- J013

- J014

- J015

- J016

- J017

- J018

- J019

- J020

- J021

- J022

- J023

- J024

- J025

- J026

- J027

- J028

- J029

- J030

- J031

- J032

- J033

- J034

- J035

- J036

- J037

- J038

- J039

- J040

- J041

- J042

- J043

- J044

- J045

- J046

- J047

- J048

- J049

- J050

- J051

- J052

- J053

- J054

- J055

- J056

- J057

- J058

- J059

- J060

- J061

- J062

- J063

- J064

- J065

- J066

- J067

- J068

- J069

- J070

- J071

- J072

- J073

- J074

- J075

- J076

- J077

- J078

- J079

- J080

- J081

- J082

- J083

- J084

- J085

- J086

- J087

- J088

- J089

- J090

- J091

- J092

- J093

- J094

- J095

- J096

- J097

- J098

- J099

- J100

- J101

- J102

- J103

- J104

- J105

- J106

- J107

- J108

- J109

- J110

- J111

- J112

- J113

- J114

- J115

- J116

- J117

- J118

- J119

- J120

- J121

- J122

- J123

- J124

- J125

- J126

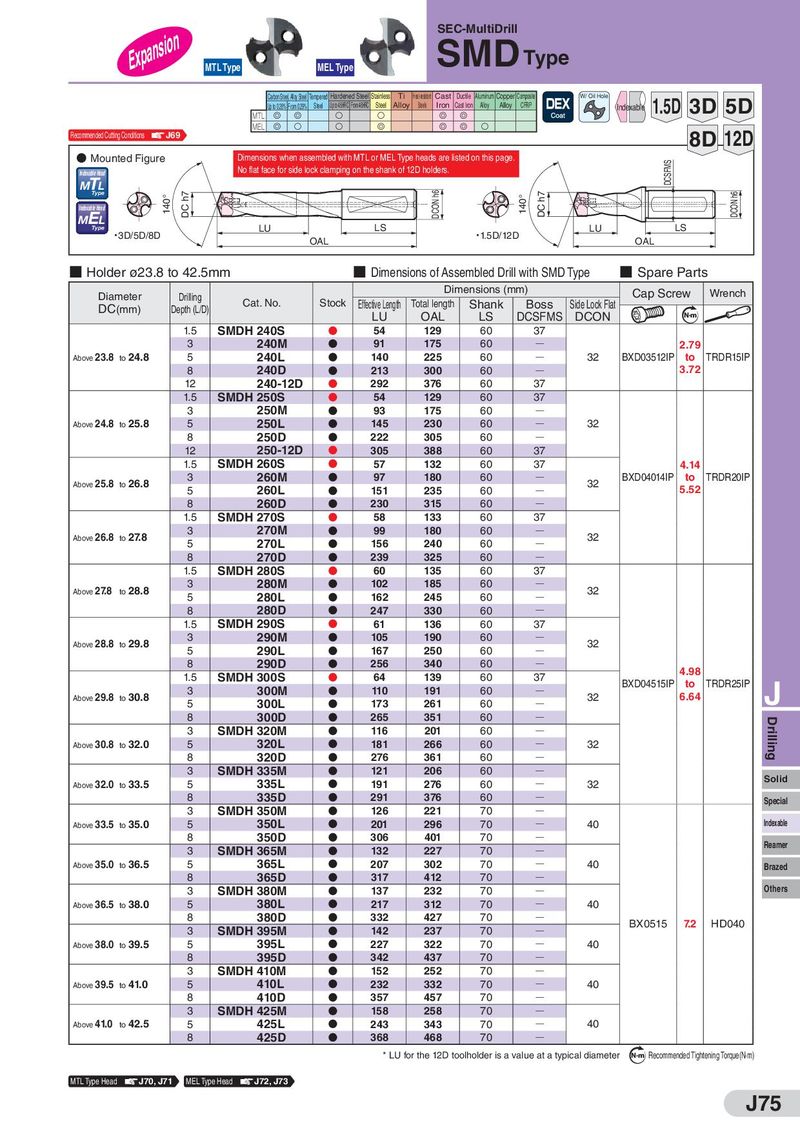

Expansion SEC-MultiDrill MTL Type MEL Type SMD Type Carbon Steel, Aloy Steel Tempered Hardened Steel Stainless Ti Heat-resistant Cast Ductile Aluminum Copper Composite W/ Oil Hole 1.5D 3D 5D Up to 0.28% From 0.29% Steel Up to 45HRC From 46HRC Steel Alloy Steels Iron Cast Iron Alloy Alloy CFRP Indexable MTL G G S S G G MEL G S S G G G S 12D Recommended Cutting Conditions J69 8D ● MouセnteッdトFi図gure 本ペDーimジen掲sio載nsのwホheルn ダasにseはmb専led用wのithMMTTLL/oMr MEELL型Tヘypッe hドeaのdsみa使re 用list願edいonまthすis。page. DCSFMS Indexable Head 12DNのo fシlatャfacンeクforにsi平de取loりckはclaあmりpinまg せonんth。e shank of 12D holders. MTL DC h7 DCON h6 Type DC h7 DCON h6 140° 140° Indexable Head MEL LU LS LU LS Type ・3D/5D/8D OAL ・1.5D/12D OAL ■ Holder ø23.8 to 42.5mm ■ Dimensions of Assembled Drill with SMD Type ■ Spare Parts Diameter Drilling Dimensions (mm) Cap Screw Wrench DC(mm) Depth (L/D) Cat. No. Stock Effective Length Total length Shank Boss Side Lock Flat LU OAL LS DCSFMS DCON Nm 1.5 SMDH 240S D 54 129 60 37 3 240M D 91 175 60 Q 2.79 Above 23.8 to 24.8 5 240L D 140 225 60 Q 32 BXD03512IP to TRDR15IP 8 240D D 213 300 60 Q 3.72 12 240-12D D 292 376 60 37 1.5 SMDH 250S D 54 129 60 37 3 250M D 93 175 60 Q Above 24.8 to 25.8 5 250L D 145 230 60 Q 32 8 250D D 222 305 60 Q 12 250-12D D 305 388 60 37 1.5 SMDH 260S D 57 132 60 37 4.14 Above 25.8 to 26.8 3 260M D 97 180 60 Q 32 BXD04014IP to TRDR20IP 5 260L D 151 235 60 Q 5.52 8 260D D 230 315 60 Q 1.5 SMDH 270S D 58 133 60 37 Above 26.8 to 27.8 3 270M D 99 180 60 Q 32 5 270L D 156 240 60 Q 8 270D D 239 325 60 Q 1.5 SMDH 280S D 60 135 60 37 Above 27.8 to 28.8 3 280M D 102 185 60 Q 32 5 280L D 162 245 60 Q 8 280D D 247 330 60 Q 1.5 SMDH 290S D 61 136 60 37 Above 28.8 to 29.8 3 290M D 105 190 60 Q 32 5 290L D 167 250 60 Q 8 290D D 256 340 60 Q 4.98 1.5 SMDH 300S D 64 139 60 37 BXD04515IP to TRDR25IP J Above 29.8 to 30.8 3 300M D 110 191 60 Q 32 6.64 5 300L D 173 261 60 Q 8 300D D 265 351 60 Q Drilling 3 SMDH 320M D 116 201 60 Q Above 30.8 to 32.0 5 320L D 181 266 60 Q 32 8 320D D 276 361 60 Q 3 SMDH 335M D 121 206 60 Q Solid Above 32.0 to 33.5 5 335L D 191 276 60 Q 32 8 335D D 291 376 60 Q Special 3 SMDH 350M D 126 221 70 Q Above 33.5 to 35.0 5 350L D 201 296 70 Q 40 Indexable 8 350D D 306 401 70 Q Reamer 3 SMDH 365M D 132 227 70 Q Above 35.0 to 36.5 5 365L D 207 302 70 Q 40 Brazed 8 365D D 317 412 70 Q 3 SMDH 380M D 137 232 70 Q Others Above 36.5 to 38.0 5 380L D 217 312 70 Q 40 8 380D D 332 427 70 Q BX0515 7.2 HD040 3 SMDH 395M D 142 237 70 Q Above 38.0 to 39.5 5 395L D 227 322 70 Q 40 8 395D D 342 437 70 Q 3 SMDH 410M D 152 252 70 Q Above 39.5 to 41.0 5 410L D 232 332 70 Q 40 8 410D D 357 457 70 Q 3 SMDH 425M D 158 258 70 Q Above 41.0 to 42.5 5 425L D 243 343 70 Q 40 8 425D D 368 468 70 Q * LU for the 12D toolholder is a value at a typical diameter N m Recommended Tightening Torque(N·m) MTL Type Head J70, J71 MEL Type Head J72, J73 J75

Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Техническая информация Sumitomo

Техническая информация Sumitomo