Каталог Sumitomo сверла и развертки - страница 71

Навигация

- J001

- J1-001

- J1-002

- J1-003

- J1-004

- J1-005

- J1-006

- J1-007

- J1-008

- J1-009

- J1-010

- J1-011

- J1-012

- J1-013

- J1-014

- J1-015

- J1-016

- J1-017

- J1-018

- J1-019

- J1-020

- J1-021

- J1-022

- J002

- J003

- J004

- J005

- J006

- J007

- J008

- J009

- J010

- J011

- J012

- J013

- J014

- J015

- J016

- J017

- J018

- J019

- J020

- J021

- J022

- J023

- J024

- J025

- J026

- J027

- J028

- J029

- J030

- J031

- J032

- J033

- J034

- J035

- J036

- J037

- J038

- J039

- J040

- J041

- J042

- J043

- J044

- J045

- J046

- J047

- J048

- J049

- J050

- J051

- J052

- J053

- J054

- J055

- J056

- J057

- J058

- J059

- J060

- J061

- J062

- J063

- J064

- J065

- J066

- J067

- J068

- J069

- J070

- J071

- J072

- J073

- J074

- J075

- J076

- J077

- J078

- J079

- J080

- J081

- J082

- J083

- J084

- J085

- J086

- J087

- J088

- J089

- J090

- J091

- J092

- J093

- J094

- J095

- J096

- J097

- J098

- J099

- J100

- J101

- J102

- J103

- J104

- J105

- J106

- J107

- J108

- J109

- J110

- J111

- J112

- J113

- J114

- J115

- J116

- J117

- J118

- J119

- J120

- J121

- J122

- J123

- J124

- J125

- J126

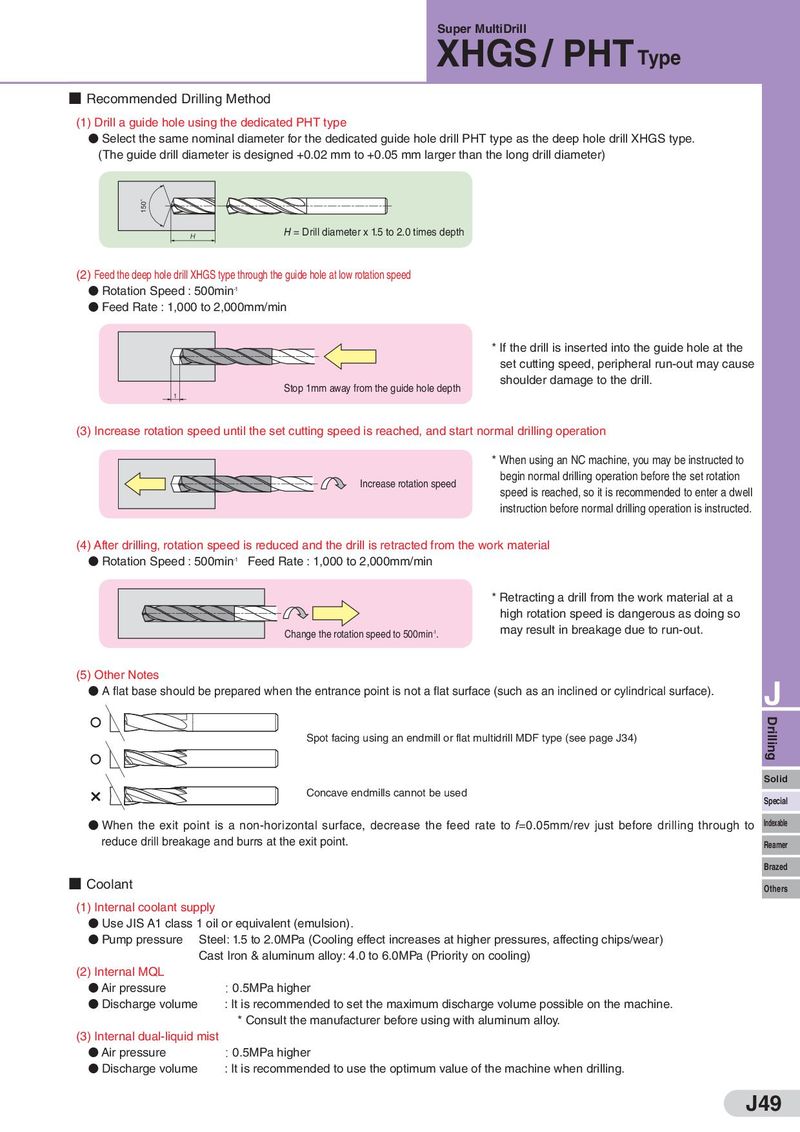

Super MultiDrill XHGS / PHT Type ■ Recommended Drilling Method (1) Drill a guide hole using the dedicated PHT type D Select the same nominal diameter for the dedicated guide hole drill PHT type as the deep hole drill XHGS type. (The guide drill diameter is designed +0.02 mm to +0.05 mm larger than the long drill diameter) 150˚ H = Drill diameter x 1.5 to 2.0 times depth (2) Feed the deep hole drill XHGS type through the guide hole at low rotation speed D Rotation Speed : 500min-1 D Feed Rate : 1,000 to 2,000mm/min * If the drill is inserted into the guide hole at the set cutting speed, peripheral run-out may cause Stop 1mm away from the guide hole depth shoulder damage to the drill. 1 (3) Increase rotation speed until the set cutting speed is reached, and start normal drilling operation * When using an NC machine, you may be instructed to Increase rotation speed begin normal drilling operation before the set rotation speed is reached, so it is recommended to enter a dwell instruction before normal drilling operation is instructed. (4) After drilling, rotation speed is reduced and the drill is retracted from the work material D Rotation Speed : 500min-1 Feed Rate : 1,000 to 2,000mm/min * Retracting a drill from the work material at a high rotation speed is dangerous as doing so Change the rotation speed to 500min-1. may result in breakage due to run-out. (5) Other Notes D A flat base should be prepared when the entrance point is not a flat surface (such as an inclined or cylindrical surface). J Spot facing using an endmill or flat multidrill MDF type (see page J34) Drilling Solid Concave endmills cannot be used Special D When the exit point is a non-horizontal surface, decrease the feed rate to f=0.05mm/rev just before drilling through to Indexable reduce drill breakage and burrs at the exit point. Reamer Brazed ■ Coolant Others (1) Internal coolant supply D Use JIS A1 class 1 oil or equivalent (emulsion). D Pump pressure Steel: 1.5 to 2.0MPa (Cooling effect increases at higher pressures, affecting chips/wear) Cast Iron & aluminum alloy: 4.0 to 6.0MPa (Priority on cooling) (2) Internal MQL D Air pressure : 0.5MPa higher D Discharge volume : It is recommended to set the maximum discharge volume possible on the machine. * Consult the manufacturer before using with aluminum alloy. (3) Internal dual-liquid mist D Air pressure : 0.5MPa higher D Discharge volume : It is recommended to use the optimum value of the machine when drilling. J49

Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Техническая информация Sumitomo

Техническая информация Sumitomo