Каталог Sumitomo сверла и развертки - страница 100

Навигация

- J001

- J1-001

- J1-002

- J1-003

- J1-004

- J1-005

- J1-006

- J1-007

- J1-008

- J1-009

- J1-010

- J1-011

- J1-012

- J1-013

- J1-014

- J1-015

- J1-016

- J1-017

- J1-018

- J1-019

- J1-020

- J1-021

- J1-022

- J002

- J003

- J004

- J005

- J006

- J007

- J008

- J009

- J010

- J011

- J012

- J013

- J014

- J015

- J016

- J017

- J018

- J019

- J020

- J021

- J022

- J023

- J024

- J025

- J026

- J027

- J028

- J029

- J030

- J031

- J032

- J033

- J034

- J035

- J036

- J037

- J038

- J039

- J040

- J041

- J042

- J043

- J044

- J045

- J046

- J047

- J048

- J049

- J050

- J051

- J052

- J053

- J054

- J055

- J056

- J057

- J058

- J059

- J060

- J061

- J062

- J063

- J064

- J065

- J066

- J067

- J068

- J069

- J070

- J071

- J072

- J073

- J074

- J075

- J076

- J077

- J078

- J079

- J080

- J081

- J082

- J083

- J084

- J085

- J086

- J087

- J088

- J089

- J090

- J091

- J092

- J093

- J094

- J095

- J096

- J097

- J098

- J099

- J100

- J101

- J102

- J103

- J104

- J105

- J106

- J107

- J108

- J109

- J110

- J111

- J112

- J113

- J114

- J115

- J116

- J117

- J118

- J119

- J120

- J121

- J122

- J123

- J124

- J125

- J126

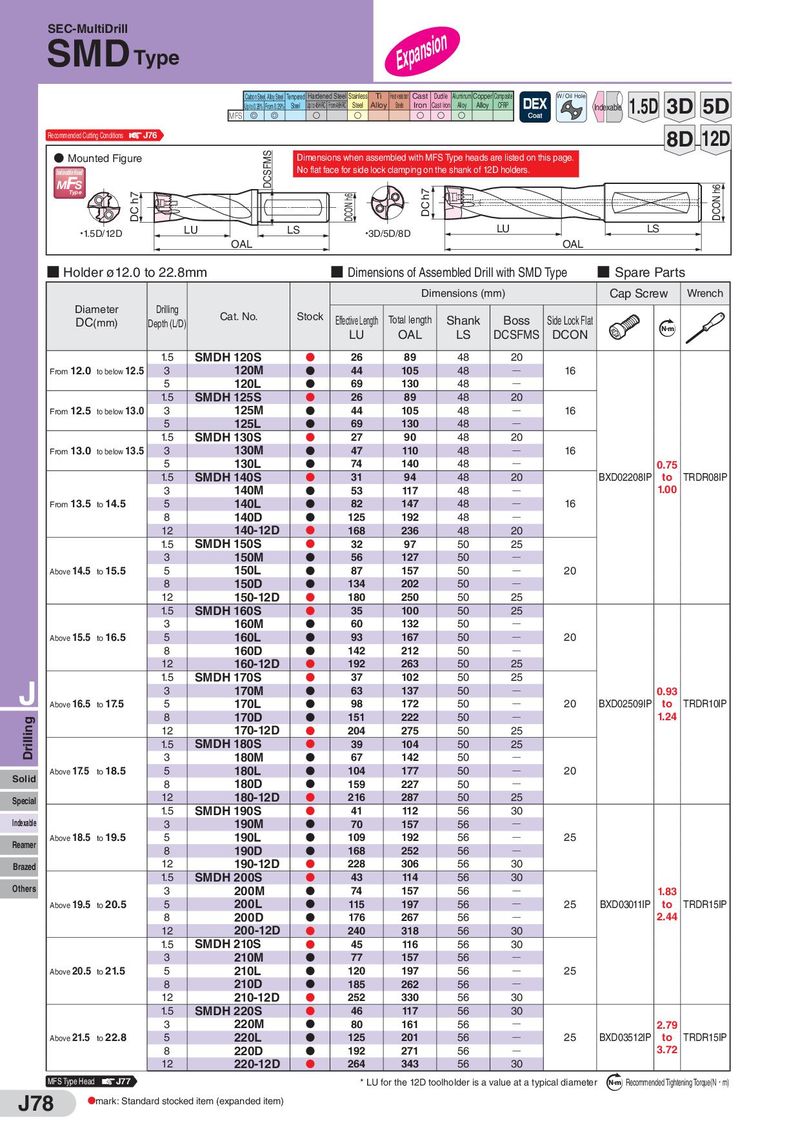

SEC-MultiDrill Expansion SMD Type Carbon Steel, Aloy Steel Tempered Hardened Steel Stainless Ti Heat-resistant Cast Ductile Aluminum Copper Composite W/ Oil Hole 1.5D 3D 5D Up to 0.28% From 0.29% Steel Up to 45HRC From 46HRC Steel Alloy Steels Iron Cast Iron Alloy Alloy CFRP Indexable MFS G G S S S S S Recommended Cutting Conditions J76 8D 12D ● Mounted Figure DCSFMS Dimensions when assembled with MFS Type heads are listed on this page. Indexable Head No flat face for side lock clamping on the shank of 12D holders. MFS DC h7 DCON h6 Type DC h7 DCON h6 ・1.5D/12D LU LS ・3D/5D/8D LU LS OAL OAL ■ Holder ø12.0 to 22.8mm ■ Dimensions of Assembled Drill with SMD Type ■ Spare Parts Dimensions (mm) Cap Screw Wrench Diameter Drilling Cat. No. Stock DC(mm) Depth (L/D) Effective Length Total length Shank Boss Side Lock Flat LU OAL LS DCSFMS DCON Nm 1.5 SMDH 120S D 26 89 48 20 From 12.0 to below 12.5 3 120M D 44 105 48 Q 16 5 120L D 69 130 48 Q 1.5 SMDH 125S D 26 89 48 20 From 12.5 to below 13.0 3 125M D 44 105 48 Q 16 5 125L D 69 130 48 Q 1.5 SMDH 130S D 27 90 48 20 From 13.0 to below 13.5 3 130M D 47 110 48 Q 16 5 130L D 74 140 48 Q 0.75 1.5 SMDH 140S D 31 94 48 20 BXD02208IP to TRDR08IP 3 140M D 53 117 48 Q 1.00 From 13.5 to 14.5 5 140L D 82 147 48 Q 16 8 140D D 125 192 48 Q 12 140-12D D 168 236 48 20 1.5 SMDH 150S D 32 97 50 25 3 150M D 56 127 50 Q Above 14.5 to 15.5 5 150L D 87 157 50 Q 20 8 150D D 134 202 50 Q 12 150-12D D 180 250 50 25 1.5 SMDH 160S D 35 100 50 25 3 160M D 60 132 50 Q Above 15.5 to 16.5 5 160L D 93 167 50 Q 20 8 160D D 142 212 50 Q 12 160-12D D 192 263 50 25 J 1.5 SMDH 170S D 37 102 50 25 3 170M D 63 137 50 Q 0.93 Above 16.5 to 17.5 5 170L D 98 172 50 Q 20 BXD02509IP to TRDR10IP Drilling 8 170D D 151 222 50 Q 1.24 12 170-12D D 204 275 50 25 1.5 SMDH 180S D 39 104 50 25 3 180M D 67 142 50 Q Solid Above 17.5 to 18.5 5 180L D 104 177 50 Q 20 8 180D D 159 227 50 Q Special 12 180-12D D 216 287 50 25 1.5 SMDH 190S D 41 112 56 30 Indexable 3 190M D 70 157 56 Q Reamer Above 18.5 to 19.5 5 190L D 109 192 56 Q 25 8 190D D 168 252 56 Q Brazed 12 190-12D D 228 306 56 30 1.5 SMDH 200S D 43 114 56 30 Others 3 200M D 74 157 56 Q 1.83 Above 19.5 to 20.5 5 200L D 115 197 56 Q 25 BXD03011IP to TRDR15IP 8 200D D 176 267 56 Q 2.44 12 200-12D D 240 318 56 30 1.5 SMDH 210S D 45 116 56 30 3 210M D 77 157 56 Q Above 20.5 to 21.5 5 210L D 120 197 56 Q 25 8 210D D 185 262 56 Q 12 210-12D D 252 330 56 30 1.5 SMDH 220S D 46 117 56 30 3 220M D 80 161 56 Q 2.79 Above 21.5 to 22.8 5 220L D 125 201 56 Q 25 BXD03512IP to TRDR15IP 8 220D D 192 271 56 Q 3.72 12 220-12D D 264 343 56 30 MFS Type Head J77 * LU for the 12D toolholder is a value at a typical diameter N m Recommended Tightening Torque(N・m) J78 Dmark: Standard stocked item (expanded item)

Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Техническая информация Sumitomo

Техническая информация Sumitomo