Каталог Sumitomo сверла и развертки - страница 142

Навигация

- J001

- J1-001

- J1-002

- J1-003

- J1-004

- J1-005

- J1-006

- J1-007

- J1-008

- J1-009

- J1-010

- J1-011

- J1-012

- J1-013

- J1-014

- J1-015

- J1-016

- J1-017

- J1-018

- J1-019

- J1-020

- J1-021

- J1-022

- J002

- J003

- J004

- J005

- J006

- J007

- J008

- J009

- J010

- J011

- J012

- J013

- J014

- J015

- J016

- J017

- J018

- J019

- J020

- J021

- J022

- J023

- J024

- J025

- J026

- J027

- J028

- J029

- J030

- J031

- J032

- J033

- J034

- J035

- J036

- J037

- J038

- J039

- J040

- J041

- J042

- J043

- J044

- J045

- J046

- J047

- J048

- J049

- J050

- J051

- J052

- J053

- J054

- J055

- J056

- J057

- J058

- J059

- J060

- J061

- J062

- J063

- J064

- J065

- J066

- J067

- J068

- J069

- J070

- J071

- J072

- J073

- J074

- J075

- J076

- J077

- J078

- J079

- J080

- J081

- J082

- J083

- J084

- J085

- J086

- J087

- J088

- J089

- J090

- J091

- J092

- J093

- J094

- J095

- J096

- J097

- J098

- J099

- J100

- J101

- J102

- J103

- J104

- J105

- J106

- J107

- J108

- J109

- J110

- J111

- J112

- J113

- J114

- J115

- J116

- J117

- J118

- J119

- J120

- J121

- J122

- J123

- J124

- J125

- J126

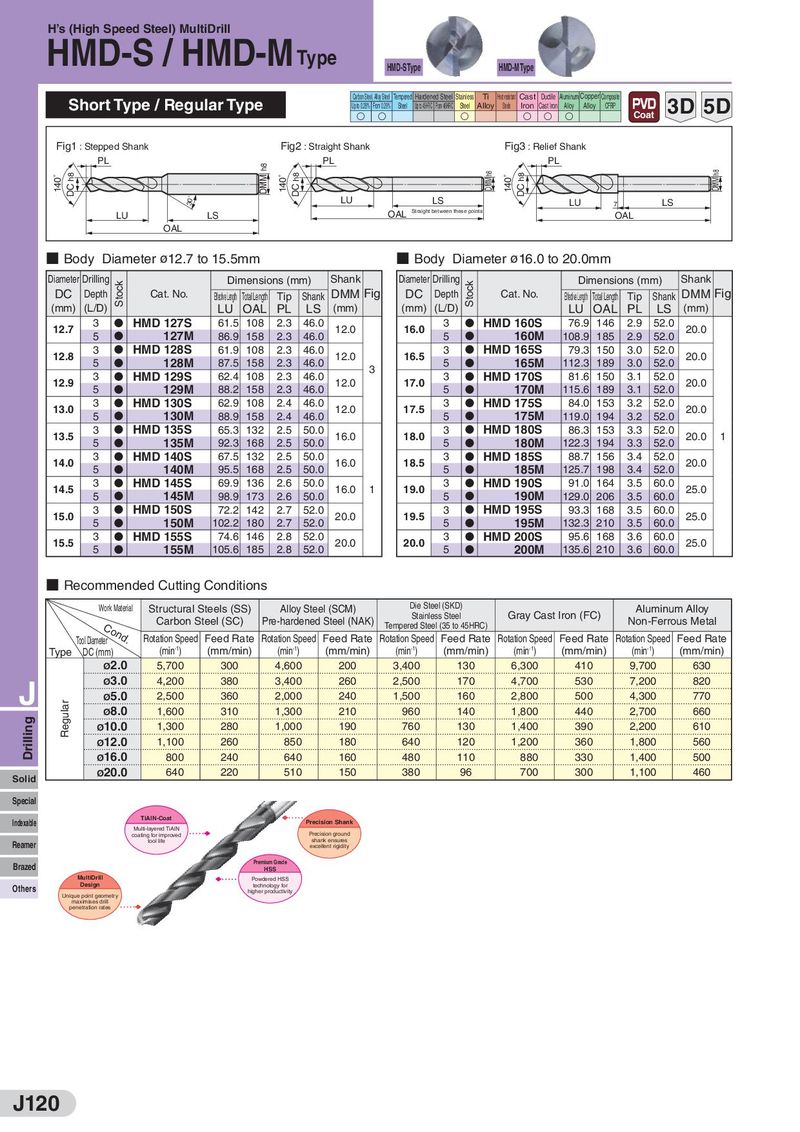

H’s (High Speed Steel) MultiDrill HMD-S / HMD-M Type HMD-S Type HMD-M Type Short Type / Regular Type Carbon Steel,Aloy Steel Tempered Hardened Steel Stainless Ti Heat-resistant Cast Ductile Aluminum Copper Composite 3D 5D Up to 0.28% From 0.29% Steel Up to 45HRC From 46HRC Steel Alloy Steels Iron Cast Iron Alloy Alloy CFRP S SD S S S S Coat Fig1 : Stepped Shank Fig2 : Straight Shank Fig3 : Relief Shank PL DMM h8 PL PL 140˚ DC h8 140˚ DC h8 DMM h8 140˚ DC h8 DMM h8 30˚ LU LS LU 7 LS LU LS OAL Straight between these points OAL OAL ■ Body Diameter ø12.7 to 15.5mm ■ Body Diameter ø16.0 to 20.0mm Diameter Drilling Stock Dimensions (mm) Shank Diameter Drilling Stock Dimensions (mm) Shank DC Depth Cat. No. EfectiveLength Total Length Tip Shank DMM Fig DC Depth Cat. No. EfectiveLength Total Length Tip Shank DMM Fig (mm) (L/D) LU OAL PL LS (mm) (mm) (L/D) LU OAL PL LS (mm) 12.7 3 D HMD 127S 61.5 108 2.3 46.0 12.0 16.0 3 D HMD 160S 76.9 146 2.9 52.0 20.0 5 D 127M 86.9 158 2.3 46.0 5 D 160M 108.9 185 2.9 52.0 12.8 3 D HMD 128S 61.9 108 2.3 46.0 12.0 16.5 3 D HMD 165S 79.3 150 3.0 52.0 20.0 5 D 128M 87.5 158 2.3 46.0 3 5 D 165M 112.3 189 3.0 52.0 12.9 3 D HMD 129S 62.4 108 2.3 46.0 12.0 17.0 3 D HMD 170S 81.6 150 3.1 52.0 20.0 5 D 129M 88.2 158 2.3 46.0 5 D 170M 115.6 189 3.1 52.0 13.0 3 D HMD 130S 62.9 108 2.4 46.0 12.0 17.5 3 D HMD 175S 84.0 153 3.2 52.0 20.0 5 D 130M 88.9 158 2.4 46.0 5 D 175M 119.0 194 3.2 52.0 13.5 3 D HMD 135S 65.3 132 2.5 50.0 16.0 18.0 3 D HMD 180S 86.3 153 3.3 52.0 20.0 1 5 D 135M 92.3 168 2.5 50.0 5 D 180M 122.3 194 3.3 52.0 14.0 3 D HMD 140S 67.5 132 2.5 50.0 16.0 18.5 3 D HMD 185S 88.7 156 3.4 52.0 20.0 5 D 140M 95.5 168 2.5 50.0 5 D 185M 125.7 198 3.4 52.0 14.5 3 D HMD 145S 69.9 136 2.6 50.0 16.0 1 19.0 3 D HMD 190S 91.0 164 3.5 60.0 25.0 5 D 145M 98.9 173 2.6 50.0 5 D 190M 129.0 206 3.5 60.0 15.0 3 D HMD 150S 72.2 142 2.7 52.0 20.0 19.5 3 D HMD 195S 93.3 168 3.5 60.0 25.0 5 D 150M 102.2 180 2.7 52.0 5 D 195M 132.3 210 3.5 60.0 15.5 3 D HMD 155S 74.6 146 2.8 52.0 20.0 20.0 3 D HMD 200S 95.6 168 3.6 60.0 25.0 5 D 155M 105.6 185 2.8 52.0 5 D 200M 135.6 210 3.6 60.0 ■ Recommended Cutting Conditions Work Material Structural Steels (SS) Alloy Steel (SCM) Die Steel (SKD) Aluminum Alloy Carbon Steel (SC) Pre-hardened Steel (NAK) Stainless Steel Gray Cast Iron (FC) Non-Ferrous Metal Tool DiameteCr ond. Tempered Steel (35 to 45HRC) Rotation Speed Feed Rate Rotation Speed Feed Rate Rotation Speed Feed Rate Rotation Speed Feed Rate Rotation Speed Feed Rate Type DC (mm) (min-1) (mm/min) (min-1) (mm/min) (min-1) (mm/min) (min-1) (mm/min) (min-1) (mm/min) ø2.0 5,700 300 4,600 200 3,400 130 6,300 410 9,700 630 J ø3.0 4,200 380 3,400 260 2,500 170 4,700 530 7,200 820 Regular ø5.0 2,500 360 2,000 240 1,500 160 2,800 500 4,300 770 Drilling ø8.0 1,600 310 1,300 210 960 140 1,800 440 2,700 660 ø10.0 1,300 280 1,000 190 760 130 1,400 390 2,200 610 ø12.0 1,100 260 850 180 640 120 1,200 360 1,800 560 ø16.0 800 240 640 160 480 110 880 330 1,400 500 Solid ø20.0 640 220 510 150 380 96 700 300 1,100 460 Special Indexable TiAlN-Coat Precision Shank Multi-layered TiAlN Precision ground coating for improved shank ensures Reamer tool life excellent rigidity Brazed Premium Grade HSS MultiDrill Powdered HSS Others Design technology for Unique point geometry higher productivity maximises drill penetration rates J120

Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Техническая информация Sumitomo

Техническая информация Sumitomo