Каталог Sumitomo сверла и развертки - страница 106

Навигация

- J001

- J1-001

- J1-002

- J1-003

- J1-004

- J1-005

- J1-006

- J1-007

- J1-008

- J1-009

- J1-010

- J1-011

- J1-012

- J1-013

- J1-014

- J1-015

- J1-016

- J1-017

- J1-018

- J1-019

- J1-020

- J1-021

- J1-022

- J002

- J003

- J004

- J005

- J006

- J007

- J008

- J009

- J010

- J011

- J012

- J013

- J014

- J015

- J016

- J017

- J018

- J019

- J020

- J021

- J022

- J023

- J024

- J025

- J026

- J027

- J028

- J029

- J030

- J031

- J032

- J033

- J034

- J035

- J036

- J037

- J038

- J039

- J040

- J041

- J042

- J043

- J044

- J045

- J046

- J047

- J048

- J049

- J050

- J051

- J052

- J053

- J054

- J055

- J056

- J057

- J058

- J059

- J060

- J061

- J062

- J063

- J064

- J065

- J066

- J067

- J068

- J069

- J070

- J071

- J072

- J073

- J074

- J075

- J076

- J077

- J078

- J079

- J080

- J081

- J082

- J083

- J084

- J085

- J086

- J087

- J088

- J089

- J090

- J091

- J092

- J093

- J094

- J095

- J096

- J097

- J098

- J099

- J100

- J101

- J102

- J103

- J104

- J105

- J106

- J107

- J108

- J109

- J110

- J111

- J112

- J113

- J114

- J115

- J116

- J117

- J118

- J119

- J120

- J121

- J122

- J123

- J124

- J125

- J126

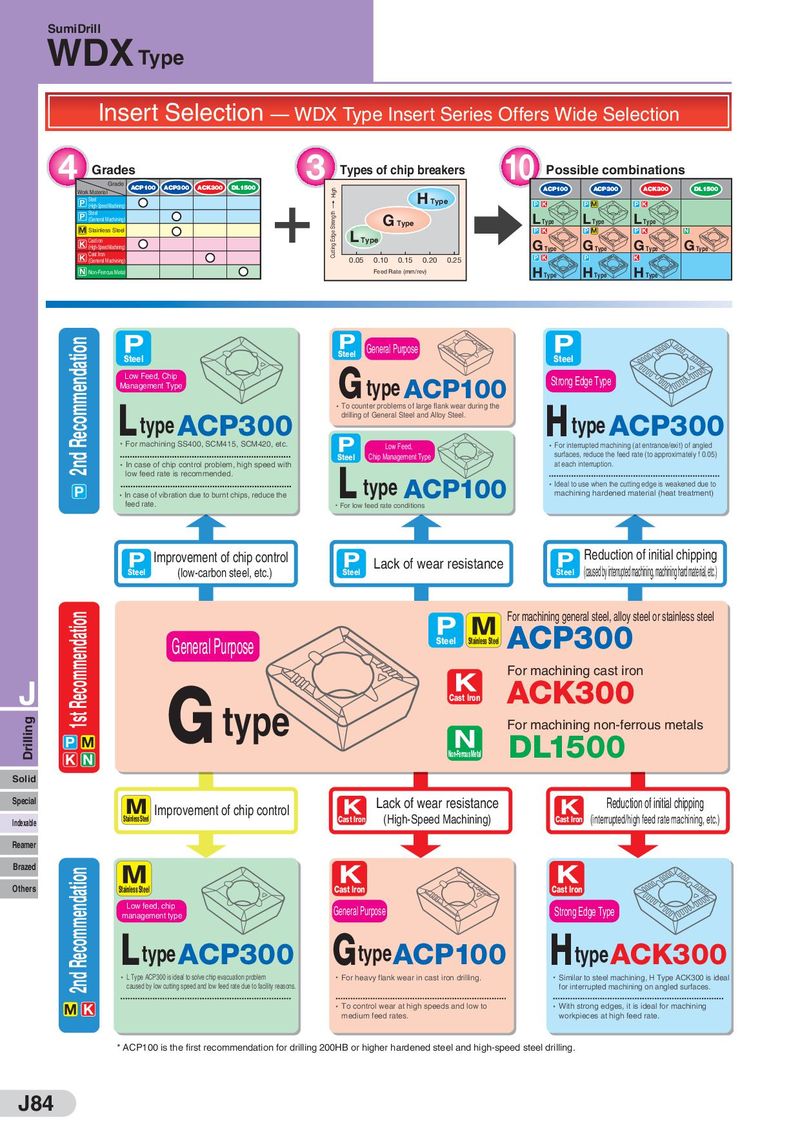

SumiDrill WDX Type Insert Selection — WDX Type Insert Series Offers Wide Selection 4 Grades 3 Types of chip breakers 10 Possible combinations Grade ACP100 ACP300 ACK300 DL1500 ACP100 ACP300 ACK300 DL1500 Work Material High H Type P Steel ↑ PK PM PK (High-Speed Machining) P Steel Cutting Edge Strength G Type L Type L Type L Type (General Machining) M Stainless Steel L Type PK PM PK N K Cast Iron G Type G Type G Type G Type (High-Speed Machining) K Cast Iron PK P K (General Machining) 0.05 0.10 0.15 0.20 0.25 N Non-Ferrous Metal Feed Rate (mm/rev) H Type H Type H Type 2nd Recommendation Steel General Purpose Steel Steel Low Feed, Chip G type ACP100 Strong Edge Type Management Type L type ACP300 ・To counter problems of large flank wear during the H type ACP300 drilling of General Steel and Alloy Steel. ・For machining SS400, SCM415, SCM420, etc. Low Feed, ・For interrupted machining (at entrance/exit) of angled Steel Chip Management Type surfaces, reduce the feed rate (to approximately f 0.05) ・In case of chip control problem, high speed with L at each interruption. low feed rate is recommended. P type ACP100 ・Ideal to use when the cutting edge is weakened due to ・In case of vibration due to burnt chips, reduce the machining hardened material (heat treatment) feed rate. ・For low feed rate conditions Improvement of chip control Lack of wear resistance Reduction of initial chipping Steel (low-carbon steel, etc.) Steel Steel (caused by interrupted machining, machining hard material, etc.) 1st Recommendation For machining general steel, alloy steel or stainless steel General Purpose Steel Stainless Steel ACP300 For machining cast iron J G type Cast Iron ACK300 Drilling For machining non-ferrous metals PM DL1500 KN Non-Ferrous Metal Solid Special Improvement of chip control Lack of wear resistance Reduction of initial chipping Indexable Stainless Steel Cast Iron (High-Speed Machining) Cast Iron (interrupted/high feed rate machining, etc.) Reamer Brazed 2nd Recommendation Others Stainless Steel Cast Iron Cast Iron Low feed, chip General Purpose Strong Edge Type management type L type ACP300 GtypeACP100 HtypeACK300 ・ L Type ACP300 is ideal to solve chip evacuation problem ・For heavy flank wear in cast iron drilling. ・ Similar to steel machining, H Type ACK300 is ideal caused by low cutting speed and low feed rate due to facility reasons. for interrupted machining on angled surfaces. MK ・ To control wear at high speeds and low to ・ With strong edges, it is ideal for machining medium feed rates. workpieces at high feed rate. * ACP100 is the first recommendation for drilling 200HB or higher hardened steel and high-speed steel drilling. J84

Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Техническая информация Sumitomo

Техническая информация Sumitomo