Каталог Sumitomo сверла и развертки - страница 132

Навигация

- J001

- J1-001

- J1-002

- J1-003

- J1-004

- J1-005

- J1-006

- J1-007

- J1-008

- J1-009

- J1-010

- J1-011

- J1-012

- J1-013

- J1-014

- J1-015

- J1-016

- J1-017

- J1-018

- J1-019

- J1-020

- J1-021

- J1-022

- J002

- J003

- J004

- J005

- J006

- J007

- J008

- J009

- J010

- J011

- J012

- J013

- J014

- J015

- J016

- J017

- J018

- J019

- J020

- J021

- J022

- J023

- J024

- J025

- J026

- J027

- J028

- J029

- J030

- J031

- J032

- J033

- J034

- J035

- J036

- J037

- J038

- J039

- J040

- J041

- J042

- J043

- J044

- J045

- J046

- J047

- J048

- J049

- J050

- J051

- J052

- J053

- J054

- J055

- J056

- J057

- J058

- J059

- J060

- J061

- J062

- J063

- J064

- J065

- J066

- J067

- J068

- J069

- J070

- J071

- J072

- J073

- J074

- J075

- J076

- J077

- J078

- J079

- J080

- J081

- J082

- J083

- J084

- J085

- J086

- J087

- J088

- J089

- J090

- J091

- J092

- J093

- J094

- J095

- J096

- J097

- J098

- J099

- J100

- J101

- J102

- J103

- J104

- J105

- J106

- J107

- J108

- J109

- J110

- J111

- J112

- J113

- J114

- J115

- J116

- J117

- J118

- J119

- J120

- J121

- J122

- J123

- J124

- J125

- J126

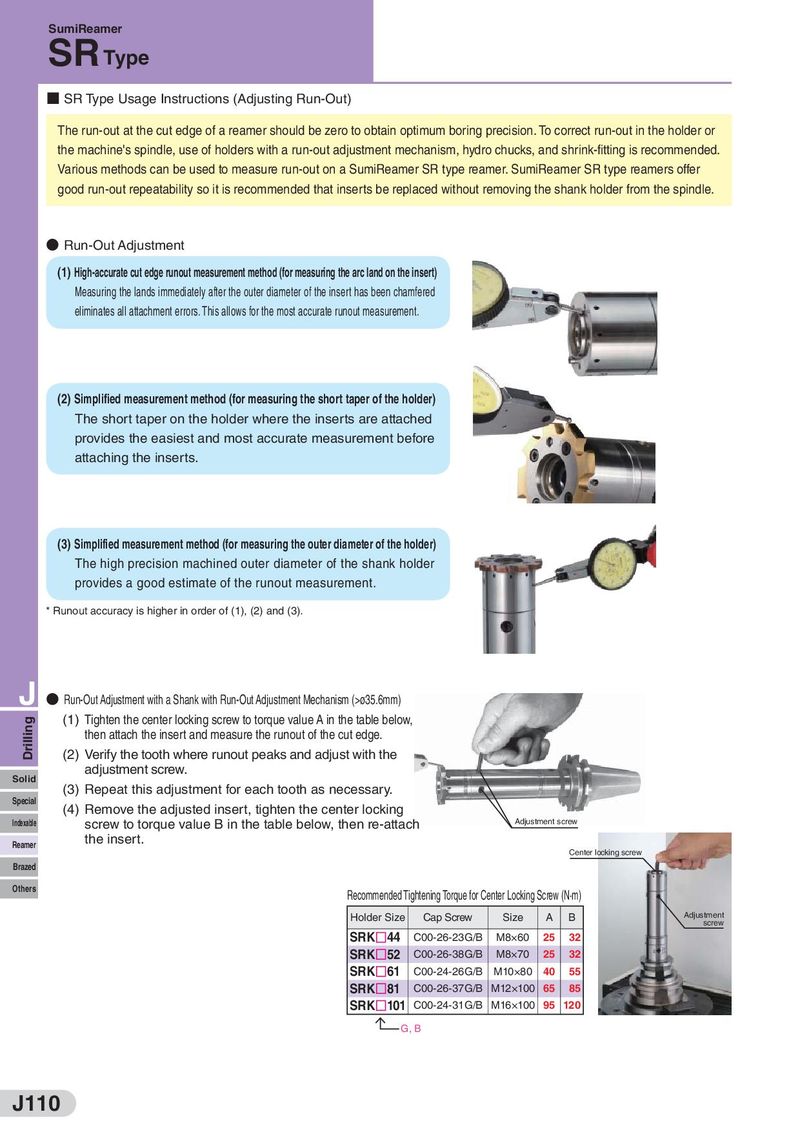

SumiReamer SR Type ■ SR Type Usage Instructions (Adjusting Run-Out) The run-out at the cut edge of a reamer should be zero to obtain optimum boring precision. To correct run-out in the holder or the machine's spindle, use of holders with a run-out adjustment mechanism, hydro chucks, and shrink-fitting is recommended. Various methods can be used to measure run-out on a SumiReamer SR type reamer. SumiReamer SR type reamers offer good run-out repeatability so it is recommended that inserts be replaced without removing the shank holder from the spindle. ● Run-Out Adjustment (1) High-accurate cut edge runout measurement method (for measuring the arc land on the insert) Measuring the lands immediately after the outer diameter of the insert has been chamfered eliminates all attachment errors. This allows for the most accurate runout measurement. (2) Simplified measurement method (for measuring the short taper of the holder) The short taper on the holder where the inserts are attached provides the easiest and most accurate measurement before attaching the inserts. (3) Simplified measurement method (for measuring the outer diameter of the holder) The high precision machined outer diameter of the shank holder provides a good estimate of the runout measurement. * Runout accuracy is higher in order of (1), (2) and (3). J ● Run-Out Adjustment with a Shank with Run-Out Adjustment Mechanism (>ø35.6mm) Drilling (1) Tighten the center locking screw to torque value A in the table below, then attach the insert and measure the runout of the cut edge. (2) Verify the tooth where runout peaks and adjust with the Solid adjustment screw. (3) Repeat this adjustment for each tooth as necessary. Special (4) Remove the adjusted insert, tighten the center locking Indexable screw to torque value B in the table below, then re-attach Adjustment screw Reamer the insert. Center locking screw Brazed Others Recommended Tightening Torque for Center Locking Screw (N·m) Holder Size Cap Screw Size A B Adjustment screw SRK 44 C00-26-23G/B M8×60 25 32 SRK 52 C00-26-38G/B M8×70 25 32 SRK 61 C00-24-26G/B M10×80 40 55 SRK 81 C00-26-37G/B M12×100 65 85 SRK 101 C00-24-31G/B M16×100 95 120 G, B J110

Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Техническая информация Sumitomo

Техническая информация Sumitomo