Каталог Sumitomo сверла и развертки - страница 64

Навигация

- J001

- J1-001

- J1-002

- J1-003

- J1-004

- J1-005

- J1-006

- J1-007

- J1-008

- J1-009

- J1-010

- J1-011

- J1-012

- J1-013

- J1-014

- J1-015

- J1-016

- J1-017

- J1-018

- J1-019

- J1-020

- J1-021

- J1-022

- J002

- J003

- J004

- J005

- J006

- J007

- J008

- J009

- J010

- J011

- J012

- J013

- J014

- J015

- J016

- J017

- J018

- J019

- J020

- J021

- J022

- J023

- J024

- J025

- J026

- J027

- J028

- J029

- J030

- J031

- J032

- J033

- J034

- J035

- J036

- J037

- J038

- J039

- J040

- J041

- J042

- J043

- J044

- J045

- J046

- J047

- J048

- J049

- J050

- J051

- J052

- J053

- J054

- J055

- J056

- J057

- J058

- J059

- J060

- J061

- J062

- J063

- J064

- J065

- J066

- J067

- J068

- J069

- J070

- J071

- J072

- J073

- J074

- J075

- J076

- J077

- J078

- J079

- J080

- J081

- J082

- J083

- J084

- J085

- J086

- J087

- J088

- J089

- J090

- J091

- J092

- J093

- J094

- J095

- J096

- J097

- J098

- J099

- J100

- J101

- J102

- J103

- J104

- J105

- J106

- J107

- J108

- J109

- J110

- J111

- J112

- J113

- J114

- J115

- J116

- J117

- J118

- J119

- J120

- J121

- J122

- J123

- J124

- J125

- J126

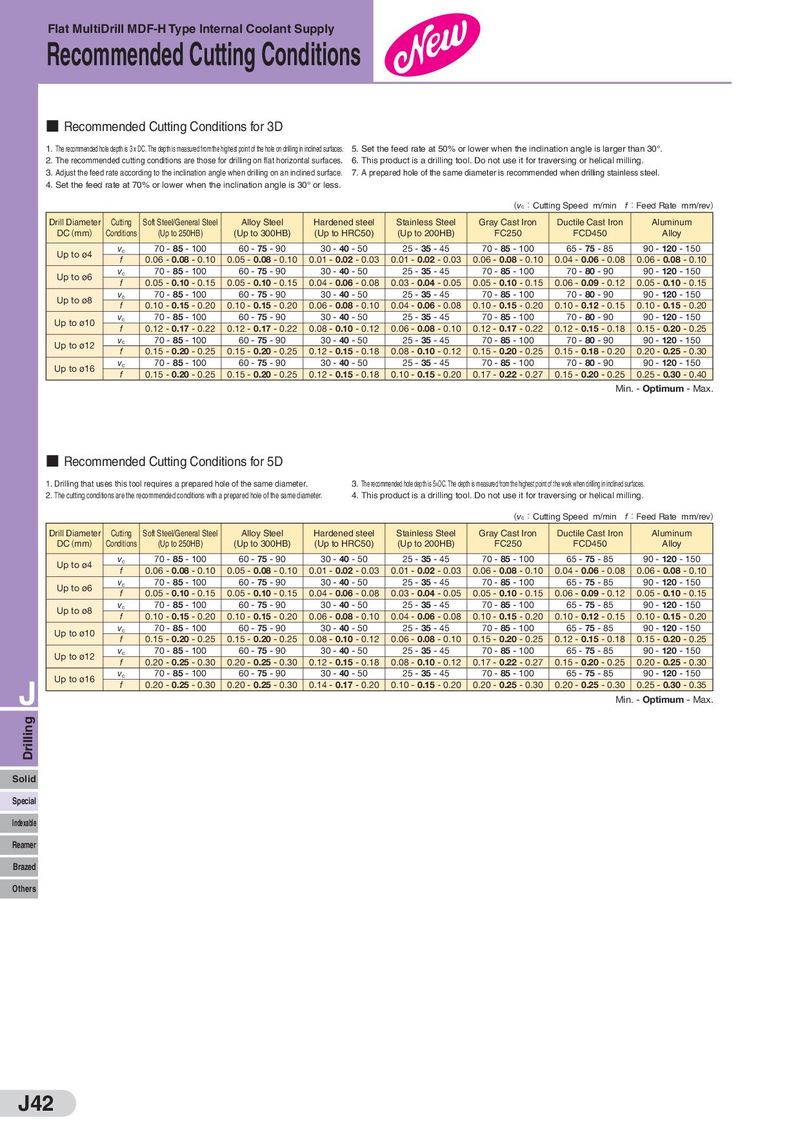

Flat MultiDrill MDF-H Type Internal Coolant Supply Recommended Cutting Conditions ■ Recommended Cutting Conditions for 3D 1. The recommended hole depth is 3 x DC. The depth is measured from the highest point of the hole on drilling in inclined surfaces. 5. Set the feed rate at 50% or lower when the inclination angle is larger than 30°. 2. The recommended cutting conditions are those for drilling on flat horizontal surfaces. 6. This product is a drilling tool. Do not use it for traversing or helical milling. 3. Adjust the feed rate according to the inclination angle when drilling on an inclined surface. 7. A prepared hole of the same diameter is recommended when drilling stainless steel. 4. Set the feed rate at 70% or lower when the inclination angle is 30° or less. (vc:Cutting Speed m/min f:Feed Rate mm/rev) Drill Diameter Cutting Soft Steel/General Steel Alloy Steel Hardened steel Stainless Steel Gray Cast Iron Ductile Cast Iron Aluminum DC (mm) Conditions (Up to 250HB) (Up to 300HB) (Up to HRC50) (Up to 200HB) FC250 FCD450 Alloy Up to ø4 vc 70 - 85 - 100 60 - 75 - 90 30 - 40 - 50 25 - 35 - 45 70 - 85 - 100 65 - 75 - 85 90 - 120 - 150 f 0.06 - 0.08 - 0.10 0.05 - 0.08 - 0.10 0.01 - 0.02 - 0.03 0.01 - 0.02 - 0.03 0.06 - 0.08 - 0.10 0.04 - 0.06 - 0.08 0.06 - 0.08 - 0.10 Up to ø6 vc 70 - 85 - 100 60 - 75 - 90 30 - 40 - 50 25 - 35 - 45 70 - 85 - 100 70 - 80 - 90 90 - 120 - 150 f 0.05 - 0.10 - 0.15 0.05 - 0.10 - 0.15 0.04 - 0.06 - 0.08 0.03 - 0.04 - 0.05 0.05 - 0.10 - 0.15 0.06 - 0.09 - 0.12 0.05 - 0.10 - 0.15 Up to ø8 vc 70 - 85 - 100 60 - 75 - 90 30 - 40 - 50 25 - 35 - 45 70 - 85 - 100 70 - 80 - 90 90 - 120 - 150 f 0.10 - 0.15 - 0.20 0.10 - 0.15 - 0.20 0.06 - 0.08 - 0.10 0.04 - 0.06 - 0.08 0.10 - 0.15 - 0.20 0.10 - 0.12 - 0.15 0.10 - 0.15 - 0.20 Up to ø10 vc 70 - 85 - 100 60 - 75 - 90 30 - 40 - 50 25 - 35 - 45 70 - 85 - 100 70 - 80 - 90 90 - 120 - 150 f 0.12 - 0.17 - 0.22 0.12 - 0.17 - 0.22 0.08 - 0.10 - 0.12 0.06 - 0.08 - 0.10 0.12 - 0.17 - 0.22 0.12 - 0.15 - 0.18 0.15 - 0.20 - 0.25 Up to ø12 vc 70 - 85 - 100 60 - 75 - 90 30 - 40 - 50 25 - 35 - 45 70 - 85 - 100 70 - 80 - 90 90 - 120 - 150 f 0.15 - 0.20 - 0.25 0.15 - 0.20 - 0.25 0.12 - 0.15 - 0.18 0.08 - 0.10 - 0.12 0.15 - 0.20 - 0.25 0.15 - 0.18 - 0.20 0.20 - 0.25 - 0.30 Up to ø16 vc 70 - 85 - 100 60 - 75 - 90 30 - 40 - 50 25 - 35 - 45 70 - 85 - 100 70 - 80 - 90 90 - 120 - 150 f 0.15 - 0.20 - 0.25 0.15 - 0.20 - 0.25 0.12 - 0.15 - 0.18 0.10 - 0.15 - 0.20 0.17 - 0.22 - 0.27 0.15 - 0.20 - 0.25 0.25 - 0.30 - 0.40 Min. - Optimum - Max. ■ Recommended Cutting Conditions for 5D 1. Drilling that uses this tool requires a prepared hole of the same diameter. 3. The recommended hole depth is 5×DC. The depth is measured from the highest point of the work when drilling in inclined surfaces. 2. The cutting conditions are the recommended conditions with a prepared hole of the same diameter. 4. This product is a drilling tool. Do not use it for traversing or helical milling. (vc:Cutting Speed m/min f:Feed Rate mm/rev) Drill Diameter Cutting Soft Steel/General Steel Alloy Steel Hardened steel Stainless Steel Gray Cast Iron Ductile Cast Iron Aluminum DC (mm) Conditions (Up to 250HB) (Up to 300HB) (Up to HRC50) (Up to 200HB) FC250 FCD450 Alloy Up to ø4 vc 70 - 85 - 100 60 - 75 - 90 30 - 40 - 50 25 - 35 - 45 70 - 85 - 100 65 - 75 - 85 90 - 120 - 150 f 0.06 - 0.08 - 0.10 0.05 - 0.08 - 0.10 0.01 - 0.02 - 0.03 0.01 - 0.02 - 0.03 0.06 - 0.08 - 0.10 0.04 - 0.06 - 0.08 0.06 - 0.08 - 0.10 Up to ø6 vc 70 - 85 - 100 60 - 75 - 90 30 - 40 - 50 25 - 35 - 45 70 - 85 - 100 65 - 75 - 85 90 - 120 - 150 f 0.05 - 0.10 - 0.15 0.05 - 0.10 - 0.15 0.04 - 0.06 - 0.08 0.03 - 0.04 - 0.05 0.05 - 0.10 - 0.15 0.06 - 0.09 - 0.12 0.05 - 0.10 - 0.15 Up to ø8 vc 70 - 85 - 100 60 - 75 - 90 30 - 40 - 50 25 - 35 - 45 70 - 85 - 100 65 - 75 - 85 90 - 120 - 150 f 0.10 - 0.15 - 0.20 0.10 - 0.15 - 0.20 0.06 - 0.08 - 0.10 0.04 - 0.06 - 0.08 0.10 - 0.15 - 0.20 0.10 - 0.12 - 0.15 0.10 - 0.15 - 0.20 Up to ø10 vc 70 - 85 - 100 60 - 75 - 90 30 - 40 - 50 25 - 35 - 45 70 - 85 - 100 65 - 75 - 85 90 - 120 - 150 f 0.15 - 0.20 - 0.25 0.15 - 0.20 - 0.25 0.08 - 0.10 - 0.12 0.06 - 0.08 - 0.10 0.15 - 0.20 - 0.25 0.12 - 0.15 - 0.18 0.15 - 0.20 - 0.25 Up to ø12 vc 70 - 85 - 100 60 - 75 - 90 30 - 40 - 50 25 - 35 - 45 70 - 85 - 100 65 - 75 - 85 90 - 120 - 150 f 0.20 - 0.25 - 0.30 0.20 - 0.25 - 0.30 0.12 - 0.15 - 0.18 0.08 - 0.10 - 0.12 0.17 - 0.22 - 0.27 0.15 - 0.20 - 0.25 0.20 - 0.25 - 0.30 Up to ø16 vc 70 - 85 - 100 60 - 75 - 90 30 - 40 - 50 25 - 35 - 45 70 - 85 - 100 65 - 75 - 85 90 - 120 - 150 J f 0.20 - 0.25 - 0.30 0.20 - 0.25 - 0.30 0.14 - 0.17 - 0.20 0.10 - 0.15 - 0.20 0.20 - 0.25 - 0.30 0.20 - 0.25 - 0.30 0.25 - 0.30 - 0.35 Min. - Optimum - Max. Drilling Solid Special Indexable Reamer Brazed Others J42

Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Техническая информация Sumitomo

Техническая информация Sumitomo