Каталог Sumitomo сверла и развертки - страница 53

Навигация

- J001

- J1-001

- J1-002

- J1-003

- J1-004

- J1-005

- J1-006

- J1-007

- J1-008

- J1-009

- J1-010

- J1-011

- J1-012

- J1-013

- J1-014

- J1-015

- J1-016

- J1-017

- J1-018

- J1-019

- J1-020

- J1-021

- J1-022

- J002

- J003

- J004

- J005

- J006

- J007

- J008

- J009

- J010

- J011

- J012

- J013

- J014

- J015

- J016

- J017

- J018

- J019

- J020

- J021

- J022

- J023

- J024

- J025

- J026

- J027

- J028

- J029

- J030

- J031

- J032

- J033

- J034

- J035

- J036

- J037

- J038

- J039

- J040

- J041

- J042

- J043

- J044

- J045

- J046

- J047

- J048

- J049

- J050

- J051

- J052

- J053

- J054

- J055

- J056

- J057

- J058

- J059

- J060

- J061

- J062

- J063

- J064

- J065

- J066

- J067

- J068

- J069

- J070

- J071

- J072

- J073

- J074

- J075

- J076

- J077

- J078

- J079

- J080

- J081

- J082

- J083

- J084

- J085

- J086

- J087

- J088

- J089

- J090

- J091

- J092

- J093

- J094

- J095

- J096

- J097

- J098

- J099

- J100

- J101

- J102

- J103

- J104

- J105

- J106

- J107

- J108

- J109

- J110

- J111

- J112

- J113

- J114

- J115

- J116

- J117

- J118

- J119

- J120

- J121

- J122

- J123

- J124

- J125

- J126

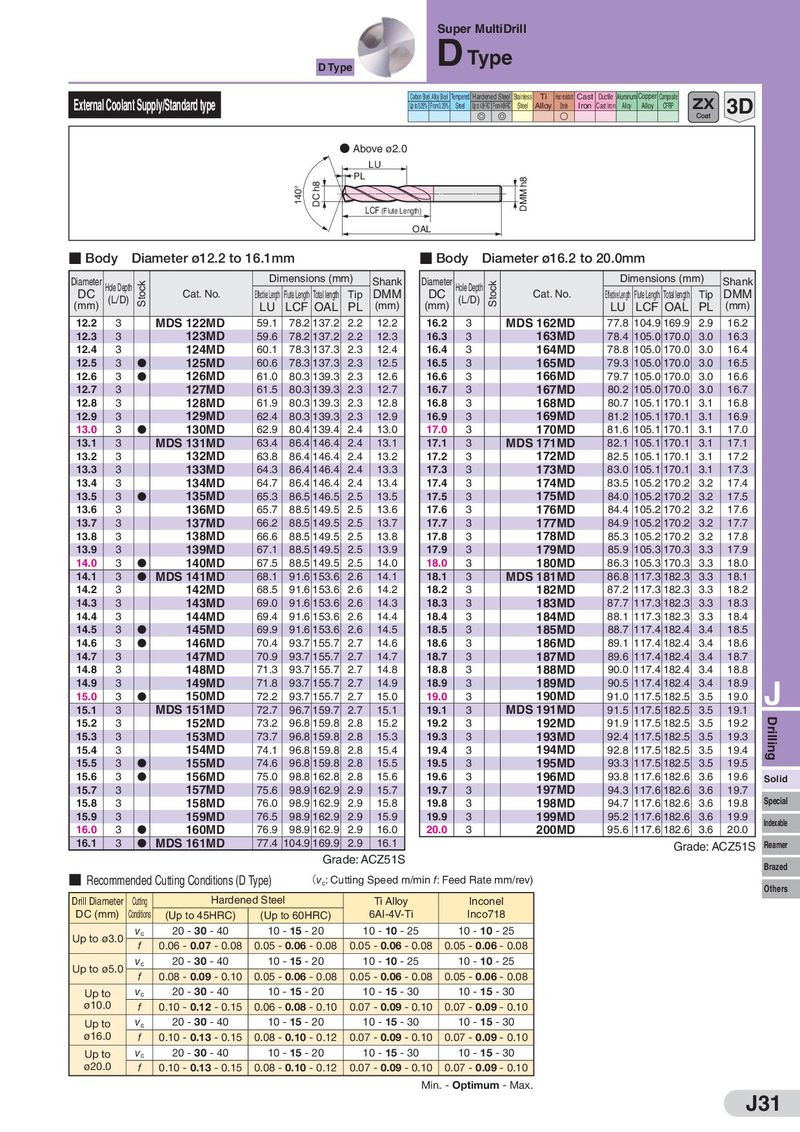

Super MultiDrill D Type D Type External Coolant Supply/Standard type Carbon Steel,Aloy Steel Tempered Hardened Steel Stainless Ti Heat-resistant Cast Ductile Aluminum Copper Composite 3D Up to 0.28% From 0.29% Steel Up to 45HRC From 46HRC Steel Alloy Steels Iron Cast Iron Alloy Alloy CFRP D G G S ● Above ø2.0 LU PL DMM h8 140° DC h8 LCF (Flute Length) OAL ■ Body Diameter ø12.2 to 16.1mm ■ Body Diameter ø16.2 to 20.0mm Diameter Hole Depth Stock Dimensions (mm) Shank Diameter Hole Depth Stock Dimensions (mm) Shank DC (L/D) Cat. No. EfectiveLength Flute Length Total length Tip DMM DC (L/D) Cat. No. EfectiveLength Flute Length Total length Tip DMM (mm) LU LCF OAL PL (mm) (mm) LU LCF OAL PL (mm) 12.2 3 MDS 122MD 59.1 78.2 137.2 2.2 12.2 16.2 3 MDS 162MD 77.8 104.9 169.9 2.9 16.2 12.3 3 123MD 59.6 78.2 137.2 2.2 12.3 16.3 3 163MD 78.4 105.0 170.0 3.0 16.3 12.4 3 124MD 60.1 78.3 137.3 2.3 12.4 16.4 3 164MD 78.8 105.0 170.0 3.0 16.4 12.5 3 D 125MD 60.6 78.3 137.3 2.3 12.5 16.5 3 165MD 79.3 105.0 170.0 3.0 16.5 12.6 3 D 126MD 61.0 80.3 139.3 2.3 12.6 16.6 3 166MD 79.7 105.0 170.0 3.0 16.6 12.7 3 127MD 61.5 80.3 139.3 2.3 12.7 16.7 3 167MD 80.2 105.0 170.0 3.0 16.7 12.8 3 128MD 61.9 80.3 139.3 2.3 12.8 16.8 3 168MD 80.7 105.1 170.1 3.1 16.8 12.9 3 129MD 62.4 80.3 139.3 2.3 12.9 16.9 3 169MD 81.2 105.1 170.1 3.1 16.9 13.0 3 D 130MD 62.9 80.4 139.4 2.4 13.0 17.0 3 170MD 81.6 105.1 170.1 3.1 17.0 13.1 3 MDS 131MD 63.4 86.4 146.4 2.4 13.1 17.1 3 MDS 171MD 82.1 105.1 170.1 3.1 17.1 13.2 3 132MD 63.8 86.4 146.4 2.4 13.2 17.2 3 172MD 82.5 105.1 170.1 3.1 17.2 13.3 3 133MD 64.3 86.4 146.4 2.4 13.3 17.3 3 173MD 83.0 105.1 170.1 3.1 17.3 13.4 3 134MD 64.7 86.4 146.4 2.4 13.4 17.4 3 174MD 83.5 105.2 170.2 3.2 17.4 13.5 3 D 135MD 65.3 86.5 146.5 2.5 13.5 17.5 3 175MD 84.0 105.2 170.2 3.2 17.5 13.6 3 136MD 65.7 88.5 149.5 2.5 13.6 17.6 3 176MD 84.4 105.2 170.2 3.2 17.6 13.7 3 137MD 66.2 88.5 149.5 2.5 13.7 17.7 3 177MD 84.9 105.2 170.2 3.2 17.7 13.8 3 138MD 66.6 88.5 149.5 2.5 13.8 17.8 3 178MD 85.3 105.2 170.2 3.2 17.8 13.9 3 139MD 67.1 88.5 149.5 2.5 13.9 17.9 3 179MD 85.9 105.3 170.3 3.3 17.9 14.0 3 D 140MD 67.5 88.5 149.5 2.5 14.0 18.0 3 180MD 86.3 105.3 170.3 3.3 18.0 14.1 3 D MDS 141MD 68.1 91.6 153.6 2.6 14.1 18.1 3 MDS 181MD 86.8 117.3 182.3 3.3 18.1 14.2 3 142MD 68.5 91.6 153.6 2.6 14.2 18.2 3 182MD 87.2 117.3 182.3 3.3 18.2 14.3 3 143MD 69.0 91.6 153.6 2.6 14.3 18.3 3 183MD 87.7 117.3 182.3 3.3 18.3 14.4 3 144MD 69.4 91.6 153.6 2.6 14.4 18.4 3 184MD 88.1 117.3 182.3 3.3 18.4 14.5 3 D 145MD 69.9 91.6 153.6 2.6 14.5 18.5 3 185MD 88.7 117.4 182.4 3.4 18.5 14.6 3 D 146MD 70.4 93.7 155.7 2.7 14.6 18.6 3 186MD 89.1 117.4 182.4 3.4 18.6 14.7 3 147MD 70.9 93.7 155.7 2.7 14.7 18.7 3 187MD 89.6 117.4 182.4 3.4 18.7 14.8 3 148MD 71.3 93.7 155.7 2.7 14.8 18.8 3 188MD 90.0 117.4 182.4 3.4 18.8 14.9 3 149MD 71.8 93.7 155.7 2.7 14.9 18.9 3 189MD 90.5 117.4 182.4 3.4 18.9 J 15.0 3 D 150MD 72.2 93.7 155.7 2.7 15.0 19.0 3 190MD 91.0 117.5 182.5 3.5 19.0 15.1 3 MDS 151MD 72.7 96.7 159.7 2.7 15.1 19.1 3 MDS 191MD 91.5 117.5 182.5 3.5 19.1 15.2 3 152MD 73.2 96.8 159.8 2.8 15.2 19.2 3 192MD 91.9 117.5 182.5 3.5 19.2 Drilling 15.3 3 153MD 73.7 96.8 159.8 2.8 15.3 19.3 3 193MD 92.4 117.5 182.5 3.5 19.3 15.4 3 154MD 74.1 96.8 159.8 2.8 15.4 19.4 3 194MD 92.8 117.5 182.5 3.5 19.4 15.5 3 D 155MD 74.6 96.8 159.8 2.8 15.5 19.5 3 195MD 93.3 117.5 182.5 3.5 19.5 15.6 3 D 156MD 75.0 98.8 162.8 2.8 15.6 19.6 3 196MD 93.8 117.6 182.6 3.6 19.6 Solid 15.7 3 157MD 75.6 98.9 162.9 2.9 15.7 19.7 3 197MD 94.3 117.6 182.6 3.6 19.7 15.8 3 158MD 76.0 98.9 162.9 2.9 15.8 19.8 3 198MD 94.7 117.6 182.6 3.6 19.8 Special 15.9 3 159MD 76.5 98.9 162.9 2.9 15.9 19.9 3 199MD 95.2 117.6 182.6 3.6 19.9 Indexable 16.0 3 D 160MD 76.9 98.9 162.9 2.9 16.0 20.0 3 200MD 95.6 117.6 182.6 3.6 20.0 16.1 3 D MDS 161MD 77.4 104.9 169.9 2.9 16.1 Grade: ACZ51S Reamer Grade: ACZ51S Brazed ■ Recommended Cutting Conditions (D Type) (vc: Cutting Speed m/min f: Feed Rate mm/rev) Others Drill Diameter Cutting Hardened Steel Ti Alloy Inconel DC (mm) Conditions (Up to 45HRC) (Up to 60HRC) 6AI-4V-Ti Inco718 Up to ø3.0 vc 20 - 30 - 40 10 - 15 - 20 10 - 10 - 25 10 - 10 - 25 f 0.06 - 0.07 - 0.08 0.05 - 0.06 - 0.08 0.05 - 0.06 - 0.08 0.05 - 0.06 - 0.08 Up to ø5.0 vc 20 - 30 - 40 10 - 15 - 20 10 - 10 - 25 10 - 10 - 25 f 0.08 - 0.09 - 0.10 0.05 - 0.06 - 0.08 0.05 - 0.06 - 0.08 0.05 - 0.06 - 0.08 Up to vc 20 - 30 - 40 10 - 15 - 20 10 - 15 - 30 10 - 15 - 30 ø10.0 f 0.10 - 0.12 - 0.15 0.06 - 0.08 - 0.10 0.07 - 0.09 - 0.10 0.07 - 0.09 - 0.10 Up to vc 20 - 30 - 40 10 - 15 - 20 10 - 15 - 30 10 - 15 - 30 ø16.0 f 0.10 - 0.13 - 0.15 0.08 - 0.10 - 0.12 0.07 - 0.09 - 0.10 0.07 - 0.09 - 0.10 Up to vc 20 - 30 - 40 10 - 15 - 20 10 - 15 - 30 10 - 15 - 30 ø20.0 f 0.10 - 0.13 - 0.15 0.08 - 0.10 - 0.12 0.07 - 0.09 - 0.10 0.07 - 0.09 - 0.10 Min. - Optimum - Max. J31

Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Техническая информация Sumitomo

Техническая информация Sumitomo