Каталог Sumitomo сверла и развертки - страница 143

Навигация

- J001

- J1-001

- J1-002

- J1-003

- J1-004

- J1-005

- J1-006

- J1-007

- J1-008

- J1-009

- J1-010

- J1-011

- J1-012

- J1-013

- J1-014

- J1-015

- J1-016

- J1-017

- J1-018

- J1-019

- J1-020

- J1-021

- J1-022

- J002

- J003

- J004

- J005

- J006

- J007

- J008

- J009

- J010

- J011

- J012

- J013

- J014

- J015

- J016

- J017

- J018

- J019

- J020

- J021

- J022

- J023

- J024

- J025

- J026

- J027

- J028

- J029

- J030

- J031

- J032

- J033

- J034

- J035

- J036

- J037

- J038

- J039

- J040

- J041

- J042

- J043

- J044

- J045

- J046

- J047

- J048

- J049

- J050

- J051

- J052

- J053

- J054

- J055

- J056

- J057

- J058

- J059

- J060

- J061

- J062

- J063

- J064

- J065

- J066

- J067

- J068

- J069

- J070

- J071

- J072

- J073

- J074

- J075

- J076

- J077

- J078

- J079

- J080

- J081

- J082

- J083

- J084

- J085

- J086

- J087

- J088

- J089

- J090

- J091

- J092

- J093

- J094

- J095

- J096

- J097

- J098

- J099

- J100

- J101

- J102

- J103

- J104

- J105

- J106

- J107

- J108

- J109

- J110

- J111

- J112

- J113

- J114

- J115

- J116

- J117

- J118

- J119

- J120

- J121

- J122

- J123

- J124

- J125

- J126

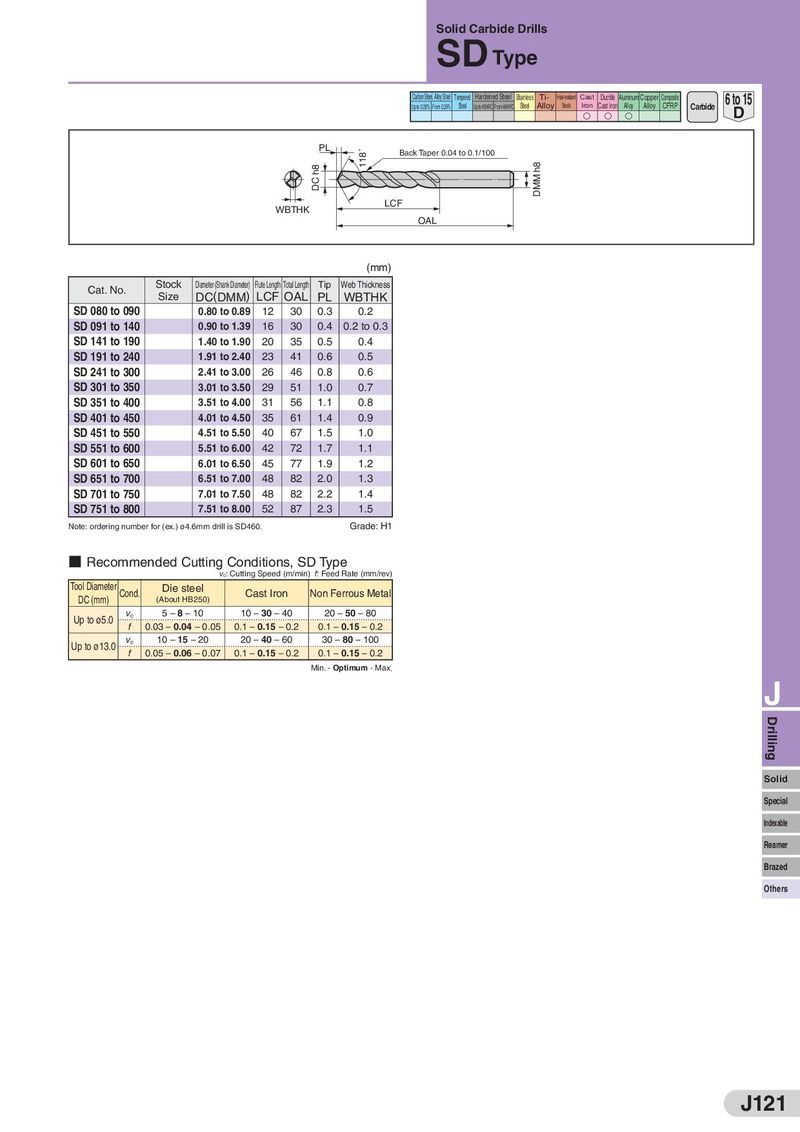

Solid Carbide Drills SD Type Carbon Steel, Aloy Steel Tempered Hardened Steel Stainless Ti- Heat-resistant Cast Ductile Aluminum Copper Composite 6 to 15 Up to 0.28% From 0.29% Steel Up to 45HRC From 46HRC Steel Alloy Steels Iron Cast Iron Alloy Alloy CFRP Carbide D S S S PL 118˚ Back Taper 0.04 to 0.1/100 DC h8 DMM h8 WBTHK LCF OAL (mm) Cat. No. Stock Diameter (Shank Diameter) Flute Length Total Length Tip Web Thickness Size DC(DMM) LCF OAL PL WBTHK SD 080 to 090 0.80 to 0.89 12 30 0.3 0.2 SD 091 to 140 0.90 to 1.39 16 30 0.4 0.2 to 0.3 SD 141 to 190 1.40 to 1.90 20 35 0.5 0.4 SD 191 to 240 1.91 to 2.40 23 41 0.6 0.5 SD 241 to 300 2.41 to 3.00 26 46 0.8 0.6 SD 301 to 350 3.01 to 3.50 29 51 1.0 0.7 SD 351 to 400 3.51 to 4.00 31 56 1.1 0.8 SD 401 to 450 4.01 to 4.50 35 61 1.4 0.9 SD 451 to 550 4.51 to 5.50 40 67 1.5 1.0 SD 551 to 600 5.51 to 6.00 42 72 1.7 1.1 SD 601 to 650 6.01 to 6.50 45 77 1.9 1.2 SD 651 to 700 6.51 to 7.00 48 82 2.0 1.3 SD 701 to 750 7.01 to 7.50 48 82 2.2 1.4 SD 751 to 800 7.51 to 8.00 52 87 2.3 1.5 Note: ordering number for (ex.) ø4.6mm drill is SD460. Grade: H1 ■ Recommended Cutting Conditions, SD Type vc: Cutting Speed (m/min) f: Feed Rate (mm/rev) Tool Diameter Cond. Die steel Cast Iron Non Ferrous Metal DC (mm) (About HB250) Up to ø5.0 vc 5 – 8 – 10 10 – 30 – 40 20 – 50 – 80 f 0.03 – 0.04 – 0.05 0.1 – 0.15 – 0.2 0.1 – 0.15 – 0.2 Up to ø13.0 vc 10 – 15 – 20 20 – 40 – 60 30 – 80 – 100 f 0.05 – 0.06 – 0.07 0.1 – 0.15 – 0.2 0.1 – 0.15 – 0.2 Min. - Optimum - Max. J Drilling Solid Special Indexable Reamer Brazed Others J121

Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Техническая информация Sumitomo

Техническая информация Sumitomo