Каталог Sumitomo сверла и развертки - страница 146

Навигация

- J001

- J1-001

- J1-002

- J1-003

- J1-004

- J1-005

- J1-006

- J1-007

- J1-008

- J1-009

- J1-010

- J1-011

- J1-012

- J1-013

- J1-014

- J1-015

- J1-016

- J1-017

- J1-018

- J1-019

- J1-020

- J1-021

- J1-022

- J002

- J003

- J004

- J005

- J006

- J007

- J008

- J009

- J010

- J011

- J012

- J013

- J014

- J015

- J016

- J017

- J018

- J019

- J020

- J021

- J022

- J023

- J024

- J025

- J026

- J027

- J028

- J029

- J030

- J031

- J032

- J033

- J034

- J035

- J036

- J037

- J038

- J039

- J040

- J041

- J042

- J043

- J044

- J045

- J046

- J047

- J048

- J049

- J050

- J051

- J052

- J053

- J054

- J055

- J056

- J057

- J058

- J059

- J060

- J061

- J062

- J063

- J064

- J065

- J066

- J067

- J068

- J069

- J070

- J071

- J072

- J073

- J074

- J075

- J076

- J077

- J078

- J079

- J080

- J081

- J082

- J083

- J084

- J085

- J086

- J087

- J088

- J089

- J090

- J091

- J092

- J093

- J094

- J095

- J096

- J097

- J098

- J099

- J100

- J101

- J102

- J103

- J104

- J105

- J106

- J107

- J108

- J109

- J110

- J111

- J112

- J113

- J114

- J115

- J116

- J117

- J118

- J119

- J120

- J121

- J122

- J123

- J124

- J125

- J126

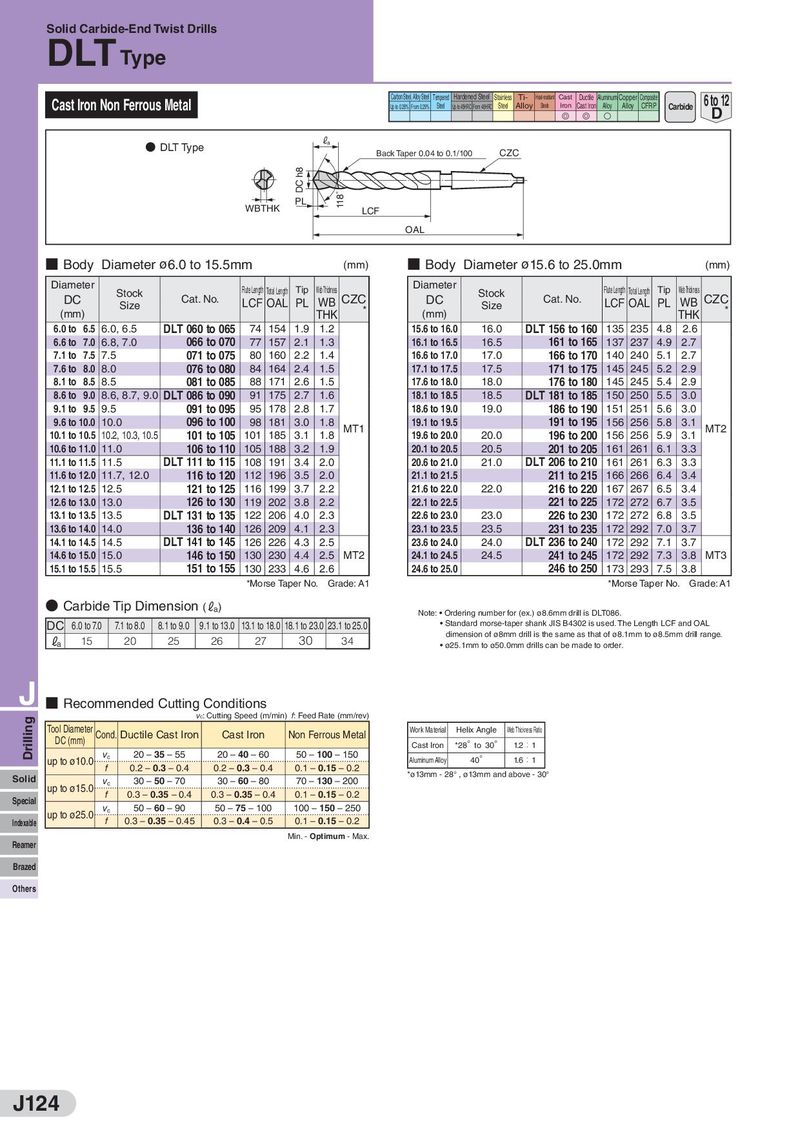

Solid Carbide-End Twist Drills DLT Type Cast Iron Non Ferrous Metal Carbon Steel, Aloy Steel Tempered Hardened Steel Stainless Ti- Heat-resistant Cast Ductile Aluminum Copper Composite 6 to 12 Up to 0.28% From 0.29% Steel Up to 45HRC From 46HRC Steel Alloy Steels Iron Cast Iron Alloy Alloy CFRP Carbide D G G S ● DLT Type La Back Taper 0.04 to 0.1/100 CZC DC h8 118˚ WBTHK PL LCF OAL ■ Body Diameter ø6.0 to 15.5mm (mm) ■ Body Diameter ø15.6 to 25.0mm (mm) Diameter Stock Flute Length Total Length Tip Web Thickness Diameter Stock Flute Length Total Length Tip Web Thickness DC Size Cat. No. LCF OAL PL WB CZC DC Size Cat. No. LCF OAL PL WB CZC (mm) THK * (mm) THK * 6.0 to 6.5 6.0, 6.5 DLT 060 to 065 74 154 1.9 1.2 15.6 to 16.0 16.0 DLT 156 to 160 135 235 4.8 2.6 6.6 to 7.0 6.8, 7.0 066 to 070 77 157 2.1 1.3 16.1 to 16.5 16.5 161 to 165 137 237 4.9 2.7 7.1 to 7.5 7.5 071 to 075 80 160 2.2 1.4 16.6 to 17.0 17.0 166 to 170 140 240 5.1 2.7 7.6 to 8.0 8.0 076 to 080 84 164 2.4 1.5 17.1 to 17.5 17.5 171 to 175 145 245 5.2 2.9 8.1 to 8.5 8.5 081 to 085 88 171 2.6 1.5 17.6 to 18.0 18.0 176 to 180 145 245 5.4 2.9 8.6 to 9.0 8.6, 8.7, 9.0 DLT 086 to 090 91 175 2.7 1.6 18.1 to 18.5 18.5 DLT 181 to 185 150 250 5.5 3.0 9.1 to 9.5 9.5 091 to 095 95 178 2.8 1.7 18.6 to 19.0 19.0 186 to 190 151 251 5.6 3.0 9.6 to 10.0 10.0 096 to 100 98 181 3.0 1.8 MT1 19.1 to 19.5 191 to 195 156 256 5.8 3.1 MT2 10.1 to 10.5 10.2, 10.3, 10.5 101 to 105 101 185 3.1 1.8 19.6 to 20.0 20.0 196 to 200 156 256 5.9 3.1 10.6 to 11.0 11.0 106 to 110 105 188 3.2 1.9 20.1 to 20.5 20.5 201 to 205 161 261 6.1 3.3 11.1 to 11.5 11.5 DLT 111 to 115 108 191 3.4 2.0 20.6 to 21.0 21.0 DLT 206 to 210 161 261 6.3 3.3 11.6 to 12.0 11.7, 12.0 116 to 120 112 196 3.5 2.0 21.1 to 21.5 211 to 215 166 266 6.4 3.4 12.1 to 12.5 12.5 121 to 125 116 199 3.7 2.2 21.6 to 22.0 22.0 216 to 220 167 267 6.5 3.4 12.6 to 13.0 13.0 126 to 130 119 202 3.8 2.2 22.1 to 22.5 221 to 225 172 272 6.7 3.5 13.1 to 13.5 13.5 DLT 131 to 135 122 206 4.0 2.3 22.6 to 23.0 23.0 226 to 230 172 272 6.8 3.5 13.6 to 14.0 14.0 136 to 140 126 209 4.1 2.3 23.1 to 23.5 23.5 231 to 235 172 292 7.0 3.7 14.1 to 14.5 14.5 DLT 141 to 145 126 226 4.3 2.5 23.6 to 24.0 24.0 DLT 236 to 240 172 292 7.1 3.7 14.6 to 15.0 15.0 146 to 150 130 230 4.4 2.5 MT2 24.1 to 24.5 24.5 241 to 245 172 292 7.3 3.8 MT3 15.1 to 15.5 15.5 151 to 155 130 233 4.6 2.6 24.6 to 25.0 246 to 250 173 293 7.5 3.8 *Morse Taper No. Grade: A1 *Morse Taper No. Grade: A1 ● Carbide Tip Dimension (La) Note: • Ordering number for (ex.) ø8.6mm drill is DLT086. DC 6.0 to 7.0 7.1 to 8.0 8.1 to 9.0 9.1 to 13.0 13.1 to 18.0 18.1 to 23.0 23.1 to 25.0 • Standard morse-taper shank JIS B4302 is used. The Length LCF and OAL La 15 20 25 26 27 30 34 dimension of ø8mm drill is the same as that of ø8.1mm to ø8.5mm drill range. • ø25.1mm to ø50.0mm drills can be made to order. J ■ Recommended Cutting Conditions Drilling vc: Cutting Speed (m/min) f: Feed Rate (mm/rev) Tool Diameter Cond. Ductile Cast Iron Cast Iron Non Ferrous Metal Work Material Helix Angle Web Thickness Ratio DC (mm) Cast Iron *28° to 30° 1.2:1 up to ø10.0 vc 20 – 35 – 55 20 – 40 – 60 50 – 100 – 150 Aluminum Alloy 40° 1.6:1 f 0.2 – 0.3 – 0.4 0.2 – 0.3 – 0.4 0.1 – 0.15 – 0.2 *ø13mm - 28° , ø13mm and above - 30° Solid up to ø15.0 vc 30 – 50 – 70 30 – 60 – 80 70 – 130 – 200 Special f 0.3 – 0.35 – 0.4 0.3 – 0.35 – 0.4 0.1 – 0.15 – 0.2 up to ø25.0 vc 50 – 60 – 90 50 – 75 – 100 100 – 150 – 250 Indexable f 0.3 – 0.35 – 0.45 0.3 – 0.4 – 0.5 0.1 – 0.15 – 0.2 Min. - Optimum - Max. Reamer Brazed Others J124

Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Техническая информация Sumitomo

Техническая информация Sumitomo