Каталог Sumitomo сверла и развертки - страница 35

Навигация

- J001

- J1-001

- J1-002

- J1-003

- J1-004

- J1-005

- J1-006

- J1-007

- J1-008

- J1-009

- J1-010

- J1-011

- J1-012

- J1-013

- J1-014

- J1-015

- J1-016

- J1-017

- J1-018

- J1-019

- J1-020

- J1-021

- J1-022

- J002

- J003

- J004

- J005

- J006

- J007

- J008

- J009

- J010

- J011

- J012

- J013

- J014

- J015

- J016

- J017

- J018

- J019

- J020

- J021

- J022

- J023

- J024

- J025

- J026

- J027

- J028

- J029

- J030

- J031

- J032

- J033

- J034

- J035

- J036

- J037

- J038

- J039

- J040

- J041

- J042

- J043

- J044

- J045

- J046

- J047

- J048

- J049

- J050

- J051

- J052

- J053

- J054

- J055

- J056

- J057

- J058

- J059

- J060

- J061

- J062

- J063

- J064

- J065

- J066

- J067

- J068

- J069

- J070

- J071

- J072

- J073

- J074

- J075

- J076

- J077

- J078

- J079

- J080

- J081

- J082

- J083

- J084

- J085

- J086

- J087

- J088

- J089

- J090

- J091

- J092

- J093

- J094

- J095

- J096

- J097

- J098

- J099

- J100

- J101

- J102

- J103

- J104

- J105

- J106

- J107

- J108

- J109

- J110

- J111

- J112

- J113

- J114

- J115

- J116

- J117

- J118

- J119

- J120

- J121

- J122

- J123

- J124

- J125

- J126

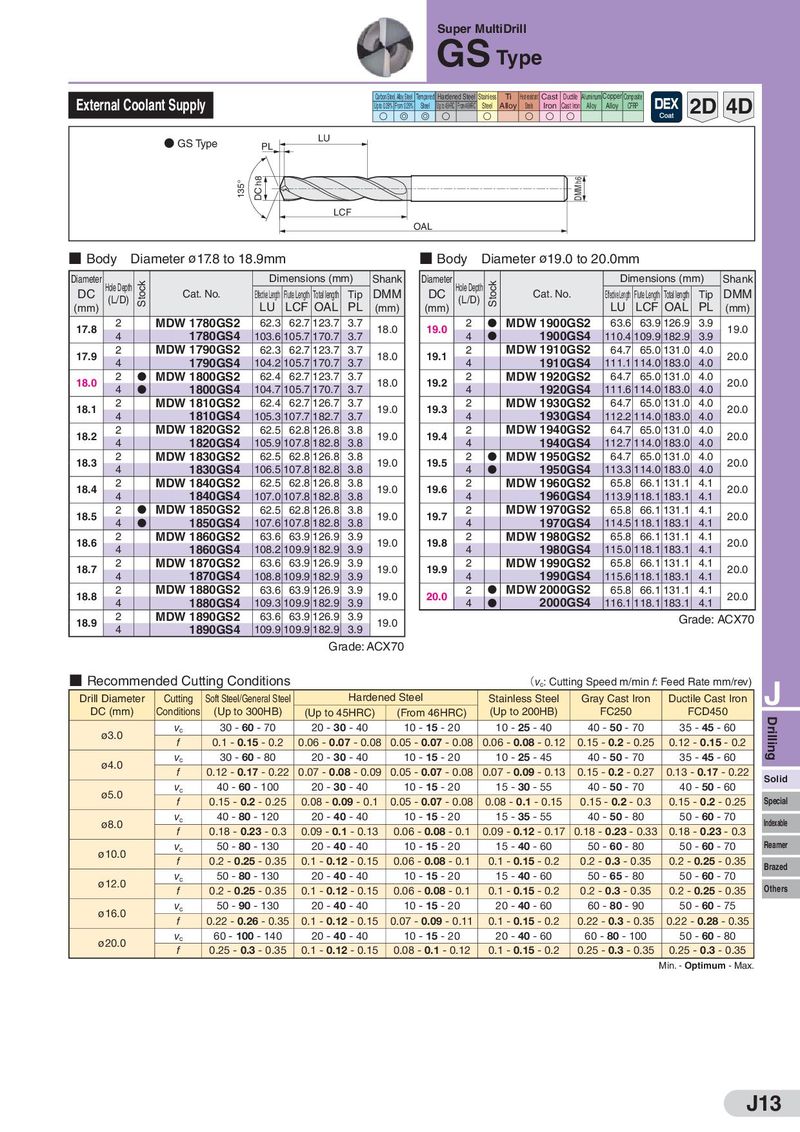

Super MultiDrill GS Type External Coolant Supply Carbon Steel,Aloy Steel Tempered Hardened Steel Stainless Ti Heat-resistant Cast Ductile Aluminum Copper Composite 2D 4D Up to 0.28% From 0.29% Steel Up to 45HRC From 46HRC Steel Alloy Steels Iron Cast Iron Alloy Alloy CFRP S GD G S S S S S ● GS Type PL LU 135° DC h8 DMM h6 LCF OAL ■ Body Diameter ø17.8 to 18.9mm ■ Body Diameter ø19.0 to 20.0mm Diameter Hole Depth Stock Dimensions (mm) Shank Diameter Hole Depth Stock Dimensions (mm) Shank DC (L/D) Cat. No. EfectiveLength Flute Length Total length Tip DMM DC (L/D) Cat. No. EfectiveLength Flute Length Total length Tip DMM (mm) LU LCF OAL PL (mm) (mm) LU LCF OAL PL (mm) 17.8 2 MDW 1780GS2 62.3 62.7 123.7 3.7 18.0 19.0 2 D MDW 1900GS2 63.6 63.9 126.9 3.9 19.0 4 1780GS4 103.6 105.7 170.7 3.7 4 D 1900GS4 110.4 109.9 182.9 3.9 17.9 2 MDW 1790GS2 62.3 62.7 123.7 3.7 18.0 19.1 2 MDW 1910GS2 64.7 65.0 131.0 4.0 20.0 4 1790GS4 104.2 105.7 170.7 3.7 4 1910GS4 111.1 114.0 183.0 4.0 18.0 2 D MDW 1800GS2 62.4 62.7 123.7 3.7 18.0 19.2 2 MDW 1920GS2 64.7 65.0 131.0 4.0 20.0 4 D 1800GS4 104.7 105.7 170.7 3.7 4 1920GS4 111.6 114.0 183.0 4.0 18.1 2 MDW 1810GS2 62.4 62.7 126.7 3.7 19.0 19.3 2 MDW 1930GS2 64.7 65.0 131.0 4.0 20.0 4 1810GS4 105.3 107.7 182.7 3.7 4 1930GS4 112.2 114.0 183.0 4.0 18.2 2 MDW 1820GS2 62.5 62.8 126.8 3.8 19.0 19.4 2 MDW 1940GS2 64.7 65.0 131.0 4.0 20.0 4 1820GS4 105.9 107.8 182.8 3.8 4 1940GS4 112.7 114.0 183.0 4.0 18.3 2 MDW 1830GS2 62.5 62.8 126.8 3.8 19.0 19.5 2 D MDW 1950GS2 64.7 65.0 131.0 4.0 20.0 4 1830GS4 106.5 107.8 182.8 3.8 4 D 1950GS4 113.3 114.0 183.0 4.0 18.4 2 MDW 1840GS2 62.5 62.8 126.8 3.8 19.0 19.6 2 MDW 1960GS2 65.8 66.1 131.1 4.1 20.0 4 1840GS4 107.0 107.8 182.8 3.8 4 1960GS4 113.9 118.1 183.1 4.1 18.5 2 D MDW 1850GS2 62.5 62.8 126.8 3.8 19.0 19.7 2 MDW 1970GS2 65.8 66.1 131.1 4.1 20.0 4 D 1850GS4 107.6 107.8 182.8 3.8 4 1970GS4 114.5 118.1 183.1 4.1 18.6 2 MDW 1860GS2 63.6 63.9 126.9 3.9 19.0 19.8 2 MDW 1980GS2 65.8 66.1 131.1 4.1 20.0 4 1860GS4 108.2 109.9 182.9 3.9 4 1980GS4 115.0 118.1 183.1 4.1 18.7 2 MDW 1870GS2 63.6 63.9 126.9 3.9 19.0 19.9 2 MDW 1990GS2 65.8 66.1 131.1 4.1 20.0 4 1870GS4 108.8 109.9 182.9 3.9 4 1990GS4 115.6 118.1 183.1 4.1 18.8 2 MDW 1880GS2 63.6 63.9 126.9 3.9 19.0 20.0 2 D MDW 2000GS2 65.8 66.1 131.1 4.1 20.0 4 1880GS4 109.3 109.9 182.9 3.9 4 D 2000GS4 116.1 118.1 183.1 4.1 18.9 2 MDW 1890GS2 63.6 63.9 126.9 3.9 19.0 Grade: ACX70 4 1890GS4 109.9 109.9 182.9 3.9 Grade: ACX70 ■ Recommended Cutting Conditions (vc: Cutting Speed m/min f: Feed Rate mm/rev) J Drill Diameter Cutting Soft Steel/General Steel Hardened Steel Stainless Steel Gray Cast Iron Ductile Cast Iron DC (mm) Conditions (Up to 300HB) (Up to 45HRC) (From 46HRC) (Up to 200HB) FC250 FCD450 Drilling ø3.0 vc 30 - 60 - 70 20 - 30 - 40 10 - 15 - 20 10 - 25 - 40 40 - 50 - 70 35 - 45 - 60 f 0.1 - 0.15 - 0.2 0.06 - 0.07 - 0.08 0.05 - 0.07 - 0.08 0.06 - 0.08 - 0.12 0.15 - 0.2 - 0.25 0.12 - 0.15 - 0.2 ø4.0 vc 30 - 60 - 80 20 - 30 - 40 10 - 15 - 20 10 - 25 - 45 40 - 50 - 70 35 - 45 - 60 f 0.12 - 0.17 - 0.22 0.07 - 0.08 - 0.09 0.05 - 0.07 - 0.08 0.07 - 0.09 - 0.13 0.15 - 0.2 - 0.27 0.13 - 0.17 - 0.22 Solid ø5.0 vc 40 - 60 - 100 20 - 30 - 40 10 - 15 - 20 15 - 30 - 55 40 - 50 - 70 40 - 50 - 60 f 0.15 - 0.2 - 0.25 0.08 - 0.09 - 0.1 0.05 - 0.07 - 0.08 0.08 - 0.1 - 0.15 0.15 - 0.2 - 0.3 0.15 - 0.2 - 0.25 Special ø8.0 vc 40 - 80 - 120 20 - 40 - 40 10 - 15 - 20 15 - 35 - 55 40 - 50 - 80 50 - 60 - 70 Indexable f 0.18 - 0.23 - 0.3 0.09 - 0.1 - 0.13 0.06 - 0.08 - 0.1 0.09 - 0.12 - 0.17 0.18 - 0.23 - 0.33 0.18 - 0.23 - 0.3 ø10.0 vc 50 - 80 - 130 20 - 40 - 40 10 - 15 - 20 15 - 40 - 60 50 - 60 - 80 50 - 60 - 70 Reamer f 0.2 - 0.25 - 0.35 0.1 - 0.12 - 0.15 0.06 - 0.08 - 0.1 0.1 - 0.15 - 0.2 0.2 - 0.3 - 0.35 0.2 - 0.25 - 0.35 Brazed ø12.0 vc 50 - 80 - 130 20 - 40 - 40 10 - 15 - 20 15 - 40 - 60 50 - 65 - 80 50 - 60 - 70 f 0.2 - 0.25 - 0.35 0.1 - 0.12 - 0.15 0.06 - 0.08 - 0.1 0.1 - 0.15 - 0.2 0.2 - 0.3 - 0.35 0.2 - 0.25 - 0.35 Others ø16.0 vc 50 - 90 - 130 20 - 40 - 40 10 - 15 - 20 20 - 40 - 60 60 - 80 - 90 50 - 60 - 75 f 0.22 - 0.26 - 0.35 0.1 - 0.12 - 0.15 0.07 - 0.09 - 0.11 0.1 - 0.15 - 0.2 0.22 - 0.3 - 0.35 0.22 - 0.28 - 0.35 ø20.0 vc 60 - 100 - 140 20 - 40 - 40 10 - 15 - 20 20 - 40 - 60 60 - 80 - 100 50 - 60 - 80 f 0.25 - 0.3 - 0.35 0.1 - 0.12 - 0.15 0.08 - 0.1 - 0.12 0.1 - 0.15 - 0.2 0.25 - 0.3 - 0.35 0.25 - 0.3 - 0.35 Min. - Optimum - Max. J13

Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Техническая информация Sumitomo

Техническая информация Sumitomo