Каталог Sumitomo сверла и развертки - страница 88

Навигация

- J001

- J1-001

- J1-002

- J1-003

- J1-004

- J1-005

- J1-006

- J1-007

- J1-008

- J1-009

- J1-010

- J1-011

- J1-012

- J1-013

- J1-014

- J1-015

- J1-016

- J1-017

- J1-018

- J1-019

- J1-020

- J1-021

- J1-022

- J002

- J003

- J004

- J005

- J006

- J007

- J008

- J009

- J010

- J011

- J012

- J013

- J014

- J015

- J016

- J017

- J018

- J019

- J020

- J021

- J022

- J023

- J024

- J025

- J026

- J027

- J028

- J029

- J030

- J031

- J032

- J033

- J034

- J035

- J036

- J037

- J038

- J039

- J040

- J041

- J042

- J043

- J044

- J045

- J046

- J047

- J048

- J049

- J050

- J051

- J052

- J053

- J054

- J055

- J056

- J057

- J058

- J059

- J060

- J061

- J062

- J063

- J064

- J065

- J066

- J067

- J068

- J069

- J070

- J071

- J072

- J073

- J074

- J075

- J076

- J077

- J078

- J079

- J080

- J081

- J082

- J083

- J084

- J085

- J086

- J087

- J088

- J089

- J090

- J091

- J092

- J093

- J094

- J095

- J096

- J097

- J098

- J099

- J100

- J101

- J102

- J103

- J104

- J105

- J106

- J107

- J108

- J109

- J110

- J111

- J112

- J113

- J114

- J115

- J116

- J117

- J118

- J119

- J120

- J121

- J122

- J123

- J124

- J125

- J126

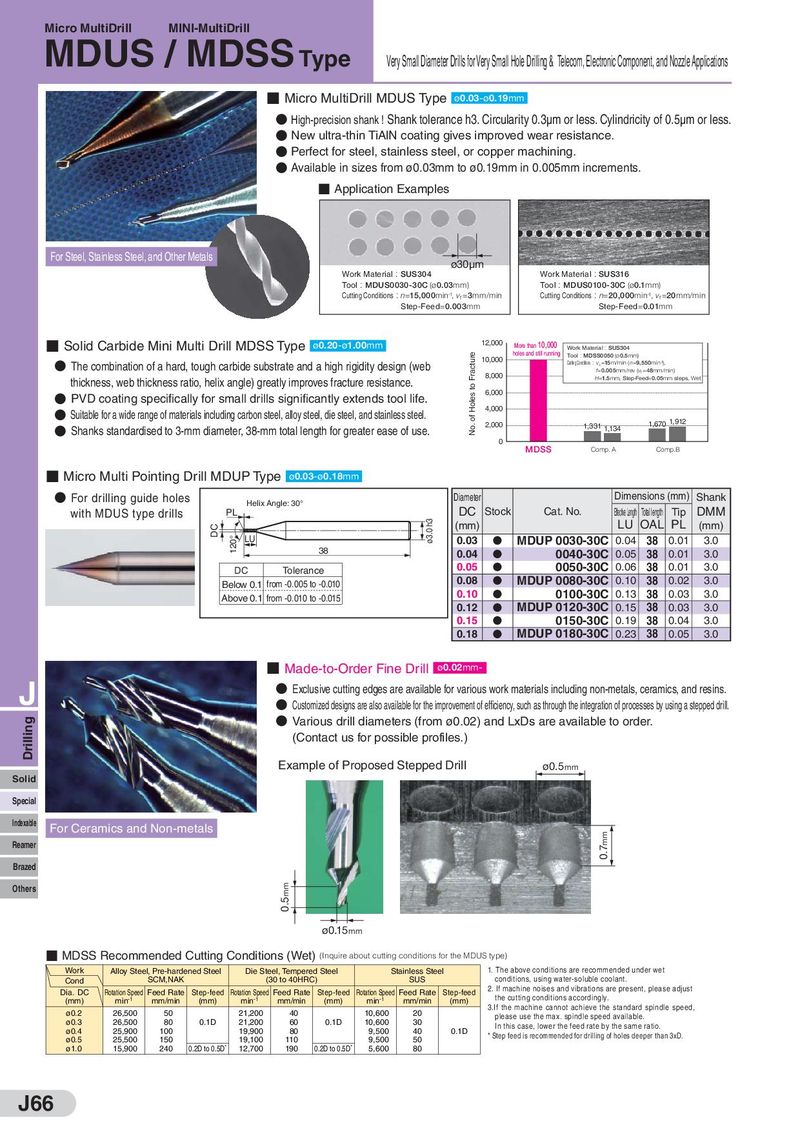

Micro MultiDrill MINI-MultiDrill MDUS / MDSS Type Very Smal Diameter Drils forVery Smal Hole Driling & Telecom, Electronic Component, and NozzleApplications ■ Micro MultiDrill MDUS Type ø0.03-ø0.19mm ● High-precision shank ! Shank tolerance h3. Circularity 0.3μm or less. Cylindricity of 0.5μm or less. ● New ultra-thin TiAlN coating gives improved wear resistance. ● Perfect for steel, stainless steel, or copper machining. ● Available in sizes from ø0.03mm to ø0.19mm in 0.005mm increments. ■ Application Examples For Steel, Stainless Steel, and Other Metals ø30μm Work Material : SUS304 Work Material : SUS316 Tool : MDUS0030-30C (ø0.03mm) Tool : MDUS0100-30C (ø0.1mm) Cutting Conditions : n=15,000min-1, vf =3mm/min Cutting Conditions : n=20,000min-1, vf =20mm/min Step-Feed=0.003mm Step-Feed=0.01mm ■ Solid Carbide Mini Multi Drill MDSS Type ø0.20-ø1.00mm 12,000 More than 10,000 Work Material : SUS304 No. of Holes to Fracture 10,000 holes and still running Tool : MDSS0050 (ø0.5mm) ● The combination of a hard, tough carbide substrate and a high rigidity design (web Cutting Conditions : vc =15m/min (n=9,550min-1), 8,000 f=0.005mm/rev (vf =48mm/min) thickness, web thickness ratio, helix angle) greatly improves fracture resistance. H=1.5mm, Step-Feed=0.05mm steps, Wet ● PVD coating specifically for small drills significantly extends tool life. 6,000 ● Suitable for a wide range of materials including carbon steel, alloy steel, die steel, and stainless steel. 4,000 ● Shanks standardised to 3-mm diameter, 38-mm total length for greater ease of use. 2,000 1,331 1,134 1,670 1,912 0 MDSS Comp. A Comp.B ■ Micro Multi Pointing Drill MDUP Type ø0.03-ø0.18mm ● For drilling guide holes Helix Angle: 30° Diameter Dimensions (mm) Shank with MDUS type drills PL DC Stock Cat. No. EfectiveLength Total length Tip DMM DC ø3.0 h3 (mm) LU OAL PL (mm) 120° LU 0.03 D MDUP 0030-30C 0.04 38 0.01 3.0 38 0.04 D 0040-30C 0.05 38 0.01 3.0 DC Tolerance 0.05 D 0050-30C 0.06 38 0.01 3.0 Below 0.1 from -0.005 to -0.010 0.08 D MDUP 0080-30C 0.10 38 0.02 3.0 Above 0.1 from -0.010 to -0.015 0.10 D 0100-30C 0.13 38 0.03 3.0 0.12 D MDUP 0120-30C 0.15 38 0.03 3.0 0.15 D 0150-30C 0.19 38 0.04 3.0 0.18 D MDUP 0180-30C 0.23 38 0.05 3.0 ■ Made-to-Order Fine Drill ø0.02mm- J ● Exclusive cutting edges are available for various work materials including non-metals, ceramics, and resins. ● Customized designs are also available for the improvement of efficiency, such as through the integration of processes by using a stepped drill. Drilling ● Various drill diameters (from ø0.02) and LxDs are available to order. (Contact us for possible profiles.) Example of Proposed Stepped Drill ø0.5mm Solid Special Indexable For Ceramics and Non-metals Reamer 0.7mm Brazed Others 0.5mm ø0.15mm ■ MDSS Recommended Cutting Conditions (Wet) (Inquire about cutting conditions for the MDUS type) Work Alloy Steel, Pre-hardened Steel Die Steel, Tempered Steel Stainless Steel 1. The above conditions are recommended under wet Cond SCM,NAK (30 to 40HRC) SUS conditions, using water-soluble coolant. Dia. DC Rotation Speed Feed Rate Step-feed Rotation Speed Feed Rate Step-feed Rotation Speed Feed Rate Step-feed 2. If machine noises and vibrations are present, please adjust (mm) min-1 mm/min (mm) min-1 mm/min (mm) min-1 mm/min (mm) the cutting conditions accordingly. ø0.2 26,500 50 21,200 40 10,600 20 3.If the machine cannot achieve the standard spindle speed, ø0.3 26,500 80 0.1D 21,200 60 0.1D 10,600 30 please use the max. spindle speed available. ø0.4 25,900 100 19,900 80 9,500 40 0.1D In this case, lower the feed rate by the same ratio. ø0.5 25,500 150 19,100 110 9,500 50 * Step feed is recommended for drilling of holes deeper than 3xD. ø1.0 15,900 240 0.2D to 0.5D* 12,700 190 0.2D to 0.5D* 5,600 80 J66

Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Техническая информация Sumitomo

Техническая информация Sumitomo