Каталог Sumitomo сверла и развертки - страница 135

Навигация

- J001

- J1-001

- J1-002

- J1-003

- J1-004

- J1-005

- J1-006

- J1-007

- J1-008

- J1-009

- J1-010

- J1-011

- J1-012

- J1-013

- J1-014

- J1-015

- J1-016

- J1-017

- J1-018

- J1-019

- J1-020

- J1-021

- J1-022

- J002

- J003

- J004

- J005

- J006

- J007

- J008

- J009

- J010

- J011

- J012

- J013

- J014

- J015

- J016

- J017

- J018

- J019

- J020

- J021

- J022

- J023

- J024

- J025

- J026

- J027

- J028

- J029

- J030

- J031

- J032

- J033

- J034

- J035

- J036

- J037

- J038

- J039

- J040

- J041

- J042

- J043

- J044

- J045

- J046

- J047

- J048

- J049

- J050

- J051

- J052

- J053

- J054

- J055

- J056

- J057

- J058

- J059

- J060

- J061

- J062

- J063

- J064

- J065

- J066

- J067

- J068

- J069

- J070

- J071

- J072

- J073

- J074

- J075

- J076

- J077

- J078

- J079

- J080

- J081

- J082

- J083

- J084

- J085

- J086

- J087

- J088

- J089

- J090

- J091

- J092

- J093

- J094

- J095

- J096

- J097

- J098

- J099

- J100

- J101

- J102

- J103

- J104

- J105

- J106

- J107

- J108

- J109

- J110

- J111

- J112

- J113

- J114

- J115

- J116

- J117

- J118

- J119

- J120

- J121

- J122

- J123

- J124

- J125

- J126

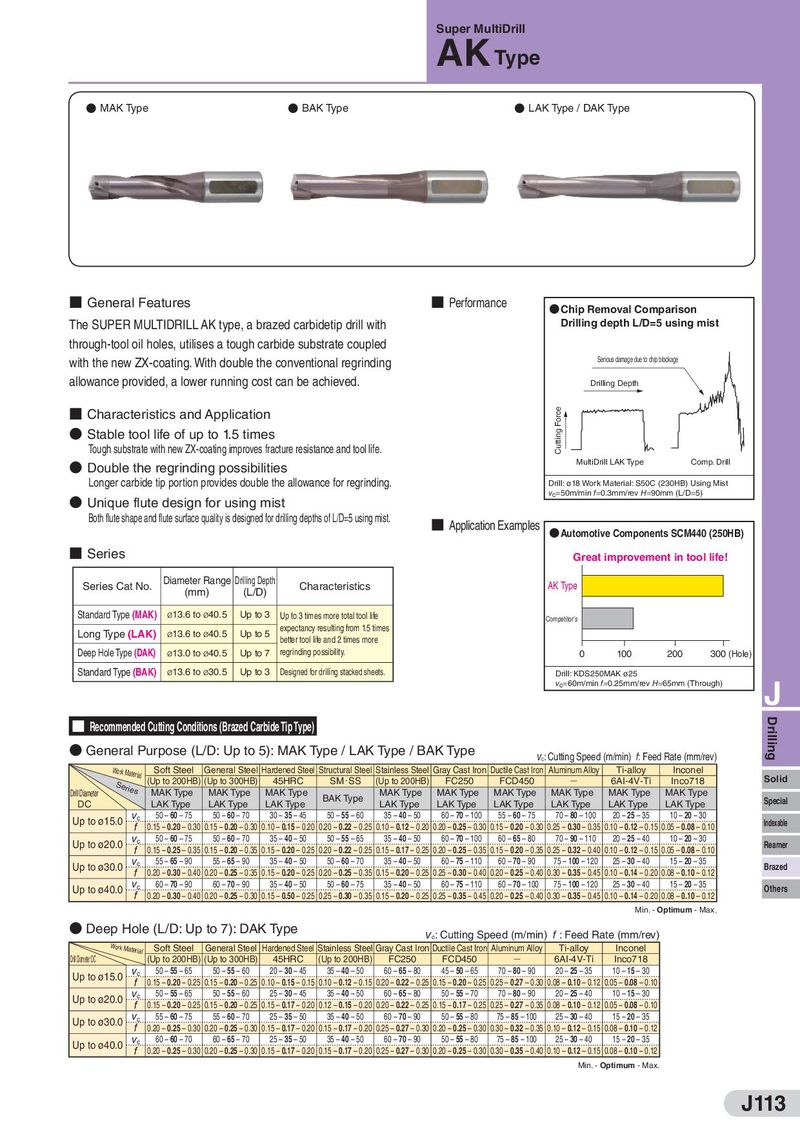

Super MultiDrill AK Type ● MAK Type ● BAK Type ● LAK Type / DAK Type ■ General Features ■ Performance ●Chip Removal Comparison The SUPER MULTIDRILL AK type, a brazed carbidetip drill with Drilling depth L/D=5 using mist through-tool oil holes, utilises a tough carbide substrate coupled with the new ZX-coating. With double the conventional regrinding Serious damage due to chip blockage allowance provided, a lower running cost can be achieved. Drilling Depth ■ Characteristics and Application Cutting Force ● Stable tool life of up to 1.5 times Tough substrate with new ZX-coating improves fracture resistance and tool life. ● Double the regrinding possibilities MultiDrill LAK Type Comp. Drill Longer carbide tip portion provides double the allowance for regrinding. Drill: ø18 Work Material: S50C (230HB) Using Mist ● Unique flute design for using mist vc=50m/min f=0.3mm/rev H=90mm (L/D=5) Both flute shape and flute surface quality is designed for drilling depths of L/D=5 using mist. ■ Application Examples ●Automotive Components SCM440 (250HB) ■ Series Great improvement in tool life! Series Cat No. Diameter Range Drilling Depth Characteristics AK Type (mm) (L/D) Standard Type (MAK) ø13.6 to ø40.5 Up to 3 Up to 3 times more total tool life Competitor’s Long Type (LAK) ø13.6 to ø40.5 Up to 5 expectancy resulting from 1.5 times better tool life and 2 times more Deep Hole Type (DAK) ø13.0 to ø40.5 Up to 7 regrinding possibility. 0 100 200 300 (Hole) Standard Type (BAK) ø13.6 to ø30.5 Up to 3 Designed for drilling stacked sheets. Drill: KDS250MAK ø25 vc=60m/min f=0.25mm/rev H=65mm (Through) J ■ Recommended Cutting Conditions (Brazed Carbide Tip Type) Drilling ● General Purpose (L/D: Up to 5): MAK Type / LAK Type / BAK Type c: Cutting Speed (m/min) f: Feed Rate (mm/rev) Work Material Soft Steel General Steel Hardened Steel Structural Steel Stainless Steel Gray Cast Iron Ductile Cast Iron Aluminum Alloy Ti-alloy Inconel Series (Up to 200HB) (Up to 300HB) 45HRC SM・SS (Up to 200HB) FC250 FCD450 − 6AI-4V-Ti Inco718 Solid Drill Diameter MAK Type MAK Type MAK Type BAK Type MAK Type MAK Type MAK Type MAK Type MAK Type MAK Type DC LAK Type LAK Type LAK Type LAK Type LAK Type LAK Type LAK Type LAK Type LAK Type Special Up to ø15.0 vc 50 – 60 – 75 50 – 60 – 70 30 – 35 – 45 50 – 55 – 60 35 – 40 – 50 60 – 70 – 100 55 – 60 – 75 70 – 80 – 100 20 – 25 – 35 10 – 20 – 30 Indexable f 0.15 – 0.20 – 0.30 0.15 – 0.20 – 0.30 0.10 – 0.15 – 0.20 0.20 – 0.22 – 0.25 0.10 – 0.12 – 0.20 0.20 – 0.25 – 0.30 0.15 – 0.20 – 0.30 0.25 – 0.30 – 0.35 0.10 – 0.12 – 0.15 0.05 – 0.08 – 0.10 Up to ø20.0 vc 50 – 60 – 75 50 – 60 – 70 35 – 40 – 50 50 – 55 – 65 35 – 40 – 50 60 – 70 – 100 60 – 65 – 80 70 – 90 – 110 20 – 25 – 40 10 – 20 – 30 Reamer f 0.15 – 0.25 – 0.35 0.15 – 0.20 – 0.35 0.15 – 0.20 – 0.25 0.20 – 0.22 – 0.25 0.15 – 0.17 – 0.25 0.20 – 0.25 – 0.35 0.15 – 0.20 – 0.35 0.25 – 0.32 – 0.40 0.10 – 0.12 – 0.15 0.05 – 0.08 – 0.10 Up to ø30.0 vc 55 – 65 – 90 55 – 65 – 90 35 – 40 – 50 50 – 60 – 70 35 – 40 – 50 60 – 75 – 110 60 – 70 – 90 75 – 100 – 120 25 – 30 – 40 15 – 20 – 35 Brazed f 0.20 – 0.30 – 0.40 0.20 – 0.25 – 0.35 0.15 – 0.20 – 0.25 0.20 – 0.25 – 0.35 0.15 – 0.20 – 0.25 0.25 – 0.30 – 0.40 0.20 – 0.25 – 0.40 0.30 – 0.35 – 0.45 0.10 – 0.14 – 0.20 0.08 – 0.10 – 0.12 Up to ø40.0 vc 60 – 70 – 90 60 – 70 – 90 35 – 40 – 50 50 – 60 – 75 35 – 40 – 50 60 – 75 – 110 60 – 70 – 100 75 – 100 – 120 25 – 30 – 40 15 – 20 – 35 Others f 0.20 – 0.30 – 0.40 0.20 – 0.25 – 0.30 0.15 – 0.50 – 0.25 0.25 – 0.30 – 0.35 0.15 – 0.20 – 0.25 0.25 – 0.35 – 0.45 0.20 – 0.25 – 0.40 0.30 – 0.35 – 0.45 0.10 – 0.14 – 0.20 0.08 – 0.10 – 0.12 Min. - Optimum - Max. ● Deep Hole (L/D: Up to 7): DAK Type c: Cutting Speed (m/min) f : Feed Rate (mm/rev) Work Material Soft Steel General Steel Hardened Steel Stainless Steel Gray Cast Iron Ductile Cast Iron Aluminum Alloy Ti-alloy Inconel Dril DiameterDC (Up to 200HB) (Up to 300HB) 45HRC (Up to 200HB) FC250 FCD450 − 6AI-4V-Ti Inco718 Up to ø15.0 vc 50 – 55 – 65 50 – 55 – 60 20 – 30 – 45 35 – 40 – 50 60 – 65 – 80 45 – 50 – 65 70 – 80 – 90 20 – 25 – 35 10 – 15 – 30 f 0.15 – 0.20 – 0.25 0.15 – 0.20 – 0.25 0.10 – 0.15 – 0.15 0.10 – 0.12 – 0.15 0.20 – 0.22 – 0.25 0.15 – 0.20 – 0.25 0.25 – 0.27 – 0.30 0.08 – 0.10 – 0.12 0.05 – 0.08 – 0.10 Up to ø20.0 vc 50 – 55 – 65 50 – 55 – 60 25 – 30 – 45 35 – 40 – 50 60 – 65 – 80 50 – 55 – 70 70 – 80 – 90 20 – 25 – 40 10 – 15 – 30 f 0.15 – 0.20 – 0.25 0.15 – 0.20 – 0.25 0.15 – 0.17 – 0.20 0.12 – 0.15 – 0.20 0.20 – 0.22 – 0.25 0.15 – 0.17 – 0.25 0.25 – 0.27 – 0.35 0.08 – 0.10 – 0.12 0.05 – 0.08 – 0.10 Up to ø30.0 vc 55 – 60 – 75 55 – 60 – 70 25 – 35 – 50 35 – 40 – 50 60 – 70 – 90 50 – 55 – 80 75 – 85 – 100 25 – 30 – 40 15 – 20 – 35 f 0.20 – 0.25 – 0.30 0.20 – 0.25 – 0.30 0.15 – 0.17 – 0.20 0.15 – 0.17 – 0.20 0.25 – 0.27 – 0.30 0.20 – 0.25 – 0.30 0.30 – 0.32 – 0.35 0.10 – 0.12 – 0.15 0.08 – 0.10 – 0.12 Up to ø40.0 vc 60 – 60 – 70 60 – 65 – 70 25 – 35 – 50 35 – 40 – 50 60 – 70 – 90 50 – 55 – 80 75 – 85 – 100 25 – 30 – 40 15 – 20 – 35 f 0.20 – 0.25 – 0.30 0.20 – 0.25 – 0.30 0.15 – 0.17 – 0.20 0.15 – 0.17 – 0.20 0.25 – 0.27 – 0.30 0.20 – 0.25 – 0.30 0.30 – 0.35 – 0.40 0.10 – 0.12 – 0.15 0.08 – 0.10 – 0.12 Min. - Optimum - Max. J113

Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Техническая информация Sumitomo

Техническая информация Sumitomo