Каталог Sumitomo сверла и развертки - страница 102

Навигация

- J001

- J1-001

- J1-002

- J1-003

- J1-004

- J1-005

- J1-006

- J1-007

- J1-008

- J1-009

- J1-010

- J1-011

- J1-012

- J1-013

- J1-014

- J1-015

- J1-016

- J1-017

- J1-018

- J1-019

- J1-020

- J1-021

- J1-022

- J002

- J003

- J004

- J005

- J006

- J007

- J008

- J009

- J010

- J011

- J012

- J013

- J014

- J015

- J016

- J017

- J018

- J019

- J020

- J021

- J022

- J023

- J024

- J025

- J026

- J027

- J028

- J029

- J030

- J031

- J032

- J033

- J034

- J035

- J036

- J037

- J038

- J039

- J040

- J041

- J042

- J043

- J044

- J045

- J046

- J047

- J048

- J049

- J050

- J051

- J052

- J053

- J054

- J055

- J056

- J057

- J058

- J059

- J060

- J061

- J062

- J063

- J064

- J065

- J066

- J067

- J068

- J069

- J070

- J071

- J072

- J073

- J074

- J075

- J076

- J077

- J078

- J079

- J080

- J081

- J082

- J083

- J084

- J085

- J086

- J087

- J088

- J089

- J090

- J091

- J092

- J093

- J094

- J095

- J096

- J097

- J098

- J099

- J100

- J101

- J102

- J103

- J104

- J105

- J106

- J107

- J108

- J109

- J110

- J111

- J112

- J113

- J114

- J115

- J116

- J117

- J118

- J119

- J120

- J121

- J122

- J123

- J124

- J125

- J126

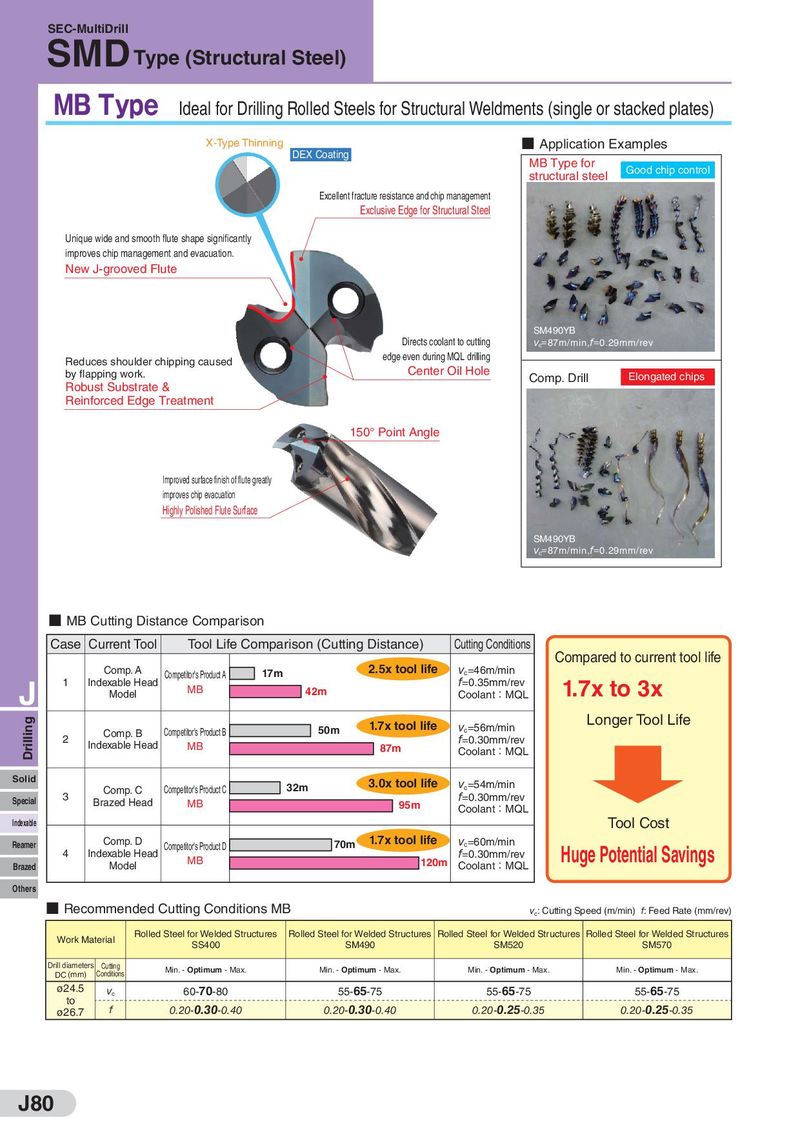

SEC-MultiDrill SMD Type (Structural Steel) MB Type Ideal for Drilling Rolled Steels for Structural Weldments (single or stacked plates) X-Type Thinning ■ Application Examples DEX Coating MB Type for structural steel Good chip control Excellent fracture resistance and chip management Exclusive Edge for Structural Steel Unique wide and smooth flute shape significantly improves chip management and evacuation. New J-grooved Flute SM490YB Directs coolant to cutting c=87m/min, =0.29mm/rev Reduces shoulder chipping caused edge even during MQL drilling by flapping work. Center Oil Hole Comp. Drill Elongated chips Robust Substrate & Reinforced Edge Treatment 150° Point Angle Improved surface finish of flute greatly improves chip evacuation Highly Polished Flute Surface SM490YB c=87m/min, =0.29mm/rev ■ MB Cutting Distance Comparison Case Current Tool Tool Life Comparison (Cutting Distance) Cutting Conditions Compared to current tool life Comp. A Competitor's Product A 17m 2.5x tool life c=46m/min J 1 Indexable Head MB 42m =0.35mm/rev 1.7x to 3x Model Coolant:MQL Drilling 50m 1.7x tool life c=56m/min Longer Tool Life 2 Comp. B Competitor's Product B =0.30mm/rev Indexable Head MB 87m Coolant:MQL Solid 32m 3.0x tool life c=54m/min 3 Comp. C Competitor's Product C =0.30mm/rev Special Brazed Head MB 95m Coolant:MQL Indexable Tool Cost Reamer Comp. D Competitor's Product D 70m 1.7x tool life c=60m/min Huge Potential Savings 4 Indexable Head MB 120m =0.30mm/rev Brazed Model Coolant:MQL Others ■ Recommended Cutting Conditions MB vc: Cutting Speed (m/min) f: Feed Rate (mm/rev) Work Material Rolled Steel for Welded Structures Rolled Steel for Welded Structures Rolled Steel for Welded Structures Rolled Steel for Welded Structures SS400 SM490 SM520 SM570 Drill diameters Cutting Min. - Optimum - Max. Min. - Optimum - Max. Min. - Optimum - Max. Min. - Optimum - Max. DC (mm) Conditions ø24.5 c 60-70-80 55-65-75 55-65-75 55-65-75 to 0.20-0.30-0.40 0.20-0.30-0.40 0.20-0.25-0.35 0.20-0.25-0.35 ø26.7 J80

Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Техническая информация Sumitomo

Техническая информация Sumitomo