Каталог Sumitomo сверла и развертки - страница 105

Навигация

- J001

- J1-001

- J1-002

- J1-003

- J1-004

- J1-005

- J1-006

- J1-007

- J1-008

- J1-009

- J1-010

- J1-011

- J1-012

- J1-013

- J1-014

- J1-015

- J1-016

- J1-017

- J1-018

- J1-019

- J1-020

- J1-021

- J1-022

- J002

- J003

- J004

- J005

- J006

- J007

- J008

- J009

- J010

- J011

- J012

- J013

- J014

- J015

- J016

- J017

- J018

- J019

- J020

- J021

- J022

- J023

- J024

- J025

- J026

- J027

- J028

- J029

- J030

- J031

- J032

- J033

- J034

- J035

- J036

- J037

- J038

- J039

- J040

- J041

- J042

- J043

- J044

- J045

- J046

- J047

- J048

- J049

- J050

- J051

- J052

- J053

- J054

- J055

- J056

- J057

- J058

- J059

- J060

- J061

- J062

- J063

- J064

- J065

- J066

- J067

- J068

- J069

- J070

- J071

- J072

- J073

- J074

- J075

- J076

- J077

- J078

- J079

- J080

- J081

- J082

- J083

- J084

- J085

- J086

- J087

- J088

- J089

- J090

- J091

- J092

- J093

- J094

- J095

- J096

- J097

- J098

- J099

- J100

- J101

- J102

- J103

- J104

- J105

- J106

- J107

- J108

- J109

- J110

- J111

- J112

- J113

- J114

- J115

- J116

- J117

- J118

- J119

- J120

- J121

- J122

- J123

- J124

- J125

- J126

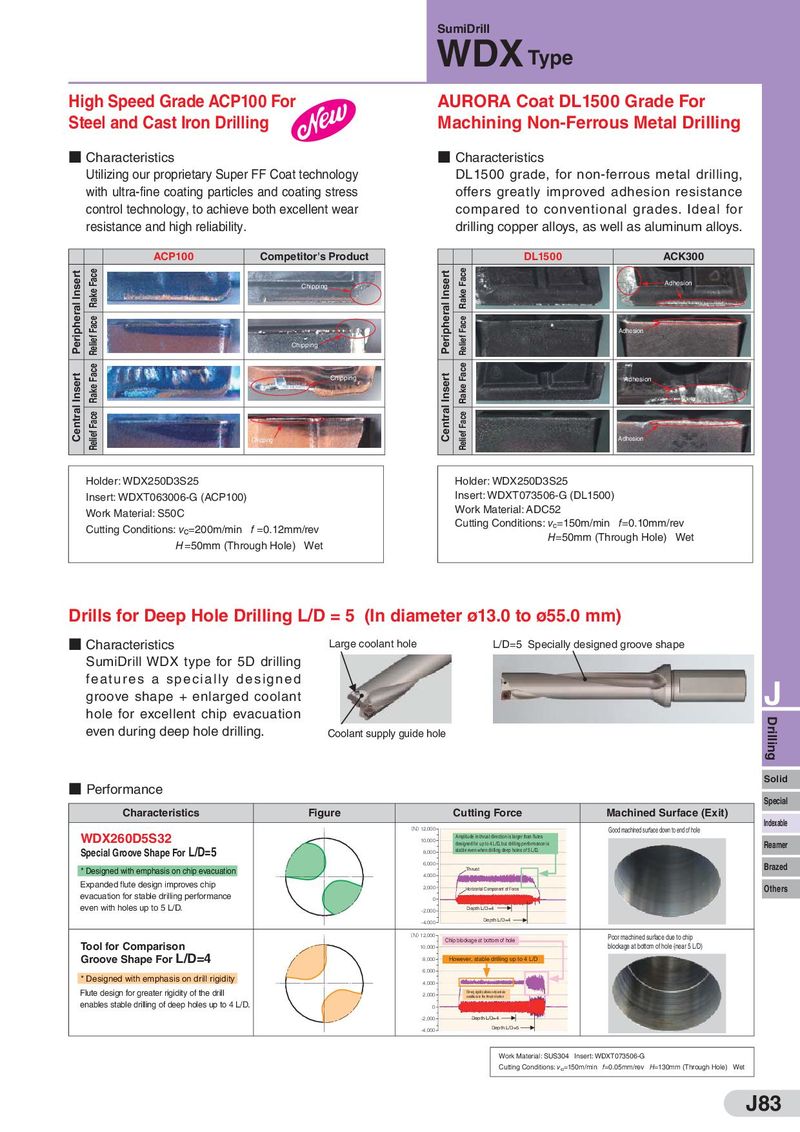

SumiDrill W DX Type High Speed Grade ACP100 For AURORA Coat DL1500 Grade For Steel and Cast Iron Drilling Machining Non-Ferrous Metal Drilling ■ Characteristics ■ Characteristics Utilizing our proprietary Super FF Coat technology DL1500 grade, for non-ferrous metal drilling, with ultra-fine coating particles and coating stress offers greatly improved adhesion resistance control technology, to achieve both excellent wear compared to conventional grades. Ideal for resistance and high reliability. drilling copper alloys, as well as aluminum alloys. ACP100 Competitor's Product DL1500 ACK300 Peripheral Insert Rake Face Chipping Peripheral Insert Rake Face Adhesion Relief Face Relief Face Adhesion Chipping Central Insert Rake Face Chipping Central Insert Rake Face Adhesion Relief Face Chipping Relief Face Adhesion Holder: WDX250D3S25 Holder: WDX250D3S25 Insert: WDXT063006-G (ACP100) Insert: WDXT073506-G (DL1500) Work Material: S50C Work Material: ADC52 Cutting Conditions: vc=200m/min f =0.12mm/rev Cutting Conditions: vc=150m/min f=0.10mm/rev H=50mm (Through Hole) Wet H=50mm (Through Hole) Wet Drills for Deep Hole Drilling L/D =5 (In diameter ø13.0 to ø55.0 mm) ■ Characteristics Large coolant hole L/D=5 Specially designed groove shape SumiDrill WDX type for 5D drilling features a specially designed J groove shape + enlarged coolant hole for excellent chip evacuation Drilling even during deep hole drilling. Coolant supply guide hole ■ Performance Solid Special Characteristics Figure Cutting Force Machined Surface (Exit) (N)12,000 Good machined surface down to end of hole Indexable WDX260D5S32 10,000 Amplitude in thrust direction is larger than flutes designed for up to 4 L/D, but drilling performance is Reamer Special Groove Shape For L/D=5 8,000 stable even when drilling deep holes of 5 L/D. 6,000 Brazed * Designed with emphasis on chip evacuation Thrust 4,000 Expanded flute design improves chip 2,000 Horizontal Component of Force Others evacuation for stable drilling performance 0 even with holes up to 5 L/D. -2,000 Depth L/D=4 -4,000 Depth L/D=4 (N)12,000 Chip blockage at bottom of hole Poor machined surface due to chip Tool for Comparison 10,000 blockage at bottom of hole (near 5 L/D) Groove Shape For L/D=4 8,000 However, stable drilling up to 4 L/D 6,000 * Designed with emphasis on drill rigidity 4,000 Flute design for greater rigidity of the drill 2,000 Strong rigidity allows only minute amplitude in the thrust direction enables stable drilling of deep holes up to 4 L/D. 0 -2,000 Depth L/D=4 -4,000 Depth L/D=5 Work Material: SUS304 Insert: WDXT073506-G Cutting Conditions: vc=150m/min f=0.05mm/rev H=130mm (Through Hole) Wet J83

Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Техническая информация Sumitomo

Техническая информация Sumitomo