Каталог Sumitomo сверла и развертки - страница 84

Навигация

- J001

- J1-001

- J1-002

- J1-003

- J1-004

- J1-005

- J1-006

- J1-007

- J1-008

- J1-009

- J1-010

- J1-011

- J1-012

- J1-013

- J1-014

- J1-015

- J1-016

- J1-017

- J1-018

- J1-019

- J1-020

- J1-021

- J1-022

- J002

- J003

- J004

- J005

- J006

- J007

- J008

- J009

- J010

- J011

- J012

- J013

- J014

- J015

- J016

- J017

- J018

- J019

- J020

- J021

- J022

- J023

- J024

- J025

- J026

- J027

- J028

- J029

- J030

- J031

- J032

- J033

- J034

- J035

- J036

- J037

- J038

- J039

- J040

- J041

- J042

- J043

- J044

- J045

- J046

- J047

- J048

- J049

- J050

- J051

- J052

- J053

- J054

- J055

- J056

- J057

- J058

- J059

- J060

- J061

- J062

- J063

- J064

- J065

- J066

- J067

- J068

- J069

- J070

- J071

- J072

- J073

- J074

- J075

- J076

- J077

- J078

- J079

- J080

- J081

- J082

- J083

- J084

- J085

- J086

- J087

- J088

- J089

- J090

- J091

- J092

- J093

- J094

- J095

- J096

- J097

- J098

- J099

- J100

- J101

- J102

- J103

- J104

- J105

- J106

- J107

- J108

- J109

- J110

- J111

- J112

- J113

- J114

- J115

- J116

- J117

- J118

- J119

- J120

- J121

- J122

- J123

- J124

- J125

- J126

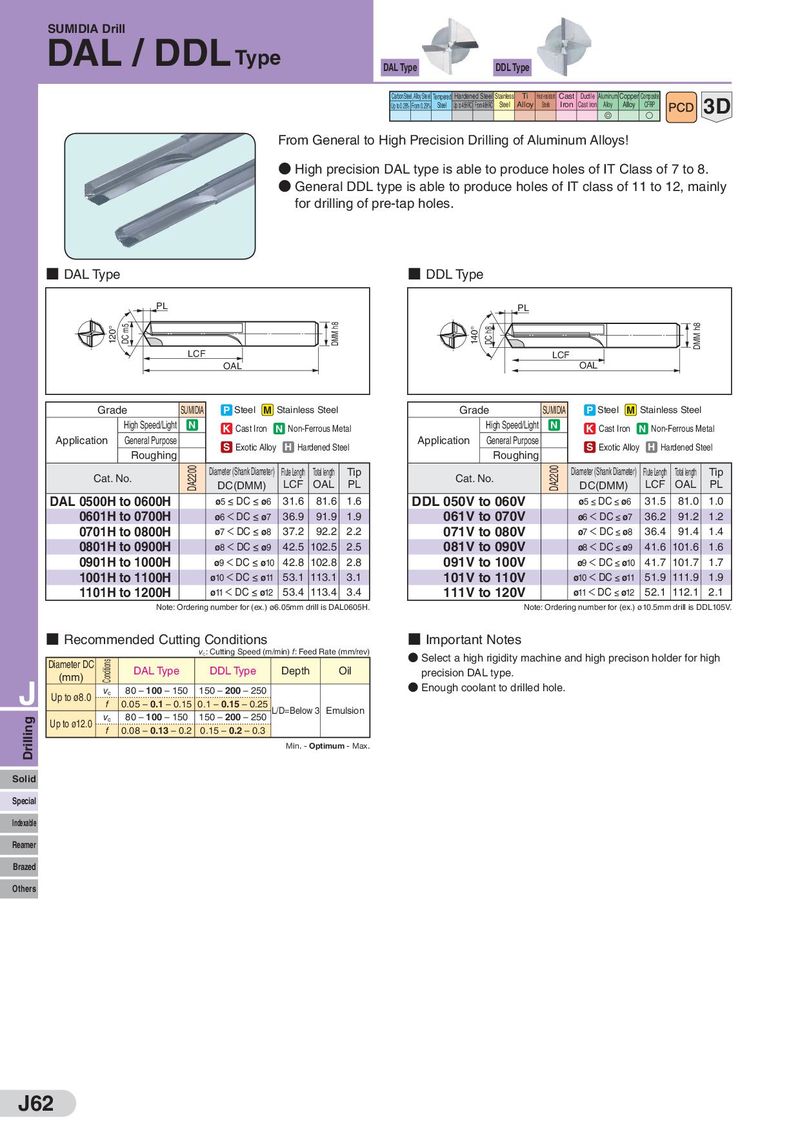

SUMIDIA Drill DAL / DDL Type DAL Type DDL Type Carbon Steel, Aloy Steel Tempered Hardened Steel Stainless Ti Heat-resistant Cast Ductile Aluminum Copper Composite 3D Up to 0.28% From 0.29% Steel Up to 45HRC From 46HRC Steel Alloy Steels Iron Cast Iron Alloy Alloy CFRP G S From General to High Precision Drilling of Aluminum Alloys! ● High precision DAL type is able to produce holes of IT Class of 7 to 8. ● General DDL type is able to produce holes of IT class of 11 to 12, mainly for drilling of pre-tap holes. ■ DAL Type ■ DDL Type PL PL 120° DC m5 DMM h8 140° DC h8 DMM h8 LCF LCF OAL OAL Grade SUMIDIA P Steel M Stainless Steel Grade SUMIDIA P Steel M Stainless Steel High Speed/Light N K Cast Iron N Non-Ferrous Metal High Speed/Light N K Cast Iron N Non-Ferrous Metal Application General Purpose S Exotic Alloy H Hardened Steel Application General Purpose S Exotic Alloy H Hardened Steel Roughing Roughing Cat. No. DA2200 Diameter (Shank Diameter) Flute Length Total length Tip Cat. No. DA2200 Diameter (Shank Diameter) Flute Length Total length Tip DC(DMM) LCF OAL PL DC(DMM) LCF OAL PL DAL 0500H to 0600H ø5 ≤ DC ≤ ø6 31.6 81.6 1.6 DDL 050V to 060V ø5 ≤ DC ≤ ø6 31.5 81.0 1.0 0601H to 0700H ø6 < DC ≤ ø7 36.9 91.9 1.9 061V to 070V ø6 < DC ≤ ø7 36.2 91.2 1.2 0701H to 0800H ø7 < DC ≤ ø8 37.2 92.2 2.2 071V to 080V ø7 < DC ≤ ø8 36.4 91.4 1.4 0801H to 0900H ø8 < DC ≤ ø9 42.5 102.5 2.5 081V to 090V ø8 < DC ≤ ø9 41.6 101.6 1.6 0901H to 1000H ø9 < DC ≤ ø10 42.8 102.8 2.8 091V to 100V ø9 < DC ≤ ø10 41.7 101.7 1.7 1001H to 1100H ø10 < DC ≤ ø11 53.1 113.1 3.1 101V to 110V ø10 < DC ≤ ø11 51.9 111.9 1.9 1101H to 1200H ø11 < DC ≤ ø12 53.4 113.4 3.4 111V to 120V ø11 < DC ≤ ø12 52.1 112.1 2.1 Note: Ordering number for (ex.) ø6.05mm drill is DAL0605H. Note: Ordering number for (ex.) ø10.5mm drill is DDL105V. ■ Recommended Cutting Conditions ■ Important Notes vc: Cutting Speed (m/min) f: Feed Rate (mm/rev) ● Select a high rigidity machine and high precison holder for high Diameter DC Conditions DAL Type DDL Type Depth Oil precision DAL type. J (mm) Up to ø8.0 vc 80 – 100 – 150 150 – 200 – 250 ● Enough coolant to drilled hole. f 0.05 – 0.1 – 0.15 0.1 – 0.15 – 0.25 L/D=Below 3 Emulsion Drilling Up to ø12.0 vc 80 – 100 – 150 150 – 200 – 250 f 0.08 – 0.13 – 0.2 0.15 – 0.2 – 0.3 Min. - Optimum - Max. Solid Special Indexable Reamer Brazed Others J62

Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Техническая информация Sumitomo

Техническая информация Sumitomo