Каталог Sumitomo сверла и развертки - страница 77

Навигация

- J001

- J1-001

- J1-002

- J1-003

- J1-004

- J1-005

- J1-006

- J1-007

- J1-008

- J1-009

- J1-010

- J1-011

- J1-012

- J1-013

- J1-014

- J1-015

- J1-016

- J1-017

- J1-018

- J1-019

- J1-020

- J1-021

- J1-022

- J002

- J003

- J004

- J005

- J006

- J007

- J008

- J009

- J010

- J011

- J012

- J013

- J014

- J015

- J016

- J017

- J018

- J019

- J020

- J021

- J022

- J023

- J024

- J025

- J026

- J027

- J028

- J029

- J030

- J031

- J032

- J033

- J034

- J035

- J036

- J037

- J038

- J039

- J040

- J041

- J042

- J043

- J044

- J045

- J046

- J047

- J048

- J049

- J050

- J051

- J052

- J053

- J054

- J055

- J056

- J057

- J058

- J059

- J060

- J061

- J062

- J063

- J064

- J065

- J066

- J067

- J068

- J069

- J070

- J071

- J072

- J073

- J074

- J075

- J076

- J077

- J078

- J079

- J080

- J081

- J082

- J083

- J084

- J085

- J086

- J087

- J088

- J089

- J090

- J091

- J092

- J093

- J094

- J095

- J096

- J097

- J098

- J099

- J100

- J101

- J102

- J103

- J104

- J105

- J106

- J107

- J108

- J109

- J110

- J111

- J112

- J113

- J114

- J115

- J116

- J117

- J118

- J119

- J120

- J121

- J122

- J123

- J124

- J125

- J126

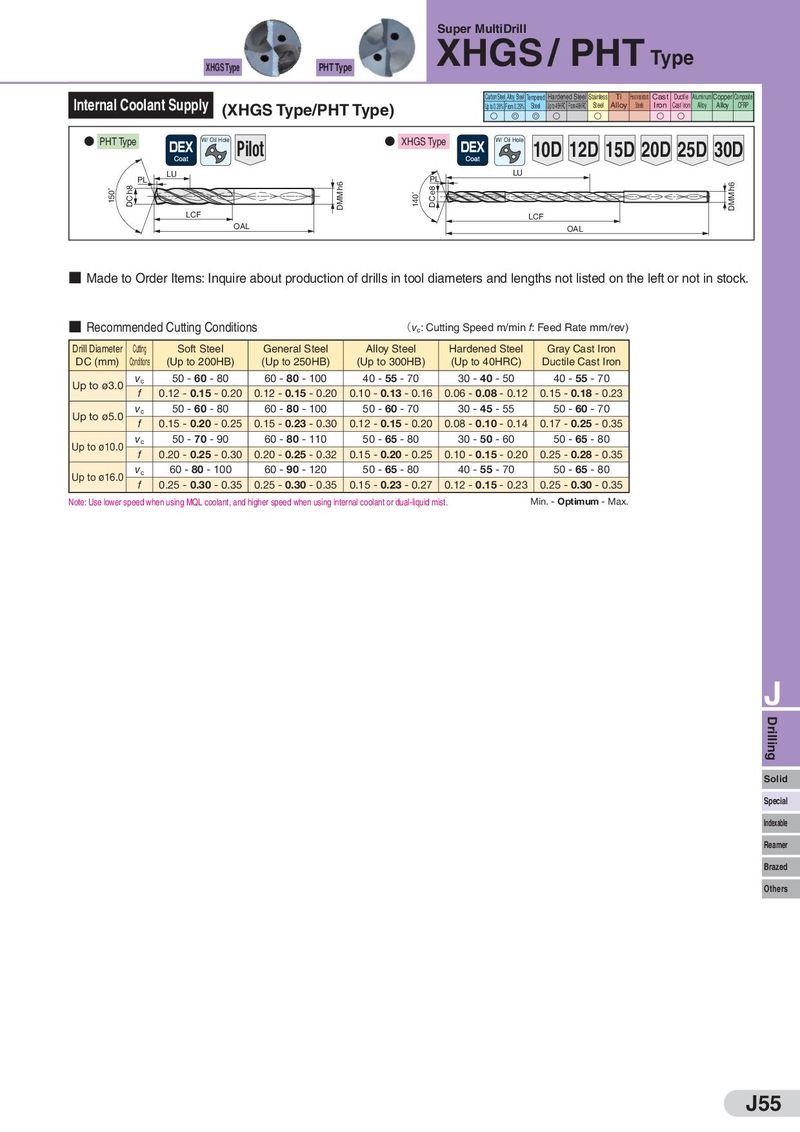

Super MultiDrill XHGS Type PHT Type XHGS / PHT Type Internal Coolant Supply Carbon Steel, Aloy Steel Tempered Hardened Steel Stainless Ti Heat-resistant Cast Ductile Aluminum Copper Composite (XHGS Type/PHT Type) Up to 0.28% From 0.29% Steel Up to 45HRC From 46HRC Steel Alloy Steels Iron Cast Iron Alloy Alloy CFRP S G G S S S S ● PHT Type W/ Oil Hole Pilot ● XHGS Type W/ Oil Hole 10D 12D 15D 20D 25D 30D PL LU PL LU 150˚ DC h8 DMM h6 140˚ DC e8 DMM h6 LCF LCF OAL OAL ■ Made to Order Items: Inquire about production of drills in tool diameters and lengths not listed on the left or not in stock. ■ Recommended Cutting Conditions (vc: Cutting Speed m/min f: Feed Rate mm/rev) Drill Diameter Cut ing Soft Steel General Steel Alloy Steel Hardened Steel Gray Cast Iron DC (mm) Conditions (Up to 200HB) (Up to 250HB) (Up to 300HB) (Up to 40HRC) Ductile Cast Iron Up to ø3.0 vc 50 - 60 - 80 60 - 80 - 100 40 - 55 - 70 30 - 40 - 50 40 - 55 - 70 f 0.12 - 0.15 - 0.20 0.12 - 0.15 - 0.20 0.10 - 0.13 - 0.16 0.06 - 0.08 - 0.12 0.15 - 0.18 - 0.23 Up to ø5.0 vc 50 - 60 - 80 60 - 80 - 100 50 - 60 - 70 30 - 45 - 55 50 - 60 - 70 f 0.15 - 0.20 - 0.25 0.15 - 0.23 - 0.30 0.12 - 0.15 - 0.20 0.08 - 0.10 - 0.14 0.17 - 0.25 - 0.35 Up to ø10.0 vc 50 - 70 - 90 60 - 80 - 110 50 - 65 - 80 30 - 50 - 60 50 - 65 - 80 f 0.20 - 0.25 - 0.30 0.20 - 0.25 - 0.32 0.15 - 0.20 - 0.25 0.10 - 0.15 - 0.20 0.25 - 0.28 - 0.35 Up to ø16.0 vc 60 - 80 - 100 60 - 90 - 120 50 - 65 - 80 40 - 55 - 70 50 - 65 - 80 f 0.25 - 0.30 - 0.35 0.25 - 0.30 - 0.35 0.15 - 0.23 - 0.27 0.12 - 0.15 - 0.23 0.25 - 0.30 - 0.35 Note: Use lower speed when using MQL coolant, and higher speed when using internal coolant or dual-liquid mist. Min. - Optimum - Max. J Drilling Solid Special Indexable Reamer Brazed Others J55

Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Техническая информация Sumitomo

Техническая информация Sumitomo