Каталог Sumitomo сверла и развертки - страница 85

Навигация

- J001

- J1-001

- J1-002

- J1-003

- J1-004

- J1-005

- J1-006

- J1-007

- J1-008

- J1-009

- J1-010

- J1-011

- J1-012

- J1-013

- J1-014

- J1-015

- J1-016

- J1-017

- J1-018

- J1-019

- J1-020

- J1-021

- J1-022

- J002

- J003

- J004

- J005

- J006

- J007

- J008

- J009

- J010

- J011

- J012

- J013

- J014

- J015

- J016

- J017

- J018

- J019

- J020

- J021

- J022

- J023

- J024

- J025

- J026

- J027

- J028

- J029

- J030

- J031

- J032

- J033

- J034

- J035

- J036

- J037

- J038

- J039

- J040

- J041

- J042

- J043

- J044

- J045

- J046

- J047

- J048

- J049

- J050

- J051

- J052

- J053

- J054

- J055

- J056

- J057

- J058

- J059

- J060

- J061

- J062

- J063

- J064

- J065

- J066

- J067

- J068

- J069

- J070

- J071

- J072

- J073

- J074

- J075

- J076

- J077

- J078

- J079

- J080

- J081

- J082

- J083

- J084

- J085

- J086

- J087

- J088

- J089

- J090

- J091

- J092

- J093

- J094

- J095

- J096

- J097

- J098

- J099

- J100

- J101

- J102

- J103

- J104

- J105

- J106

- J107

- J108

- J109

- J110

- J111

- J112

- J113

- J114

- J115

- J116

- J117

- J118

- J119

- J120

- J121

- J122

- J123

- J124

- J125

- J126

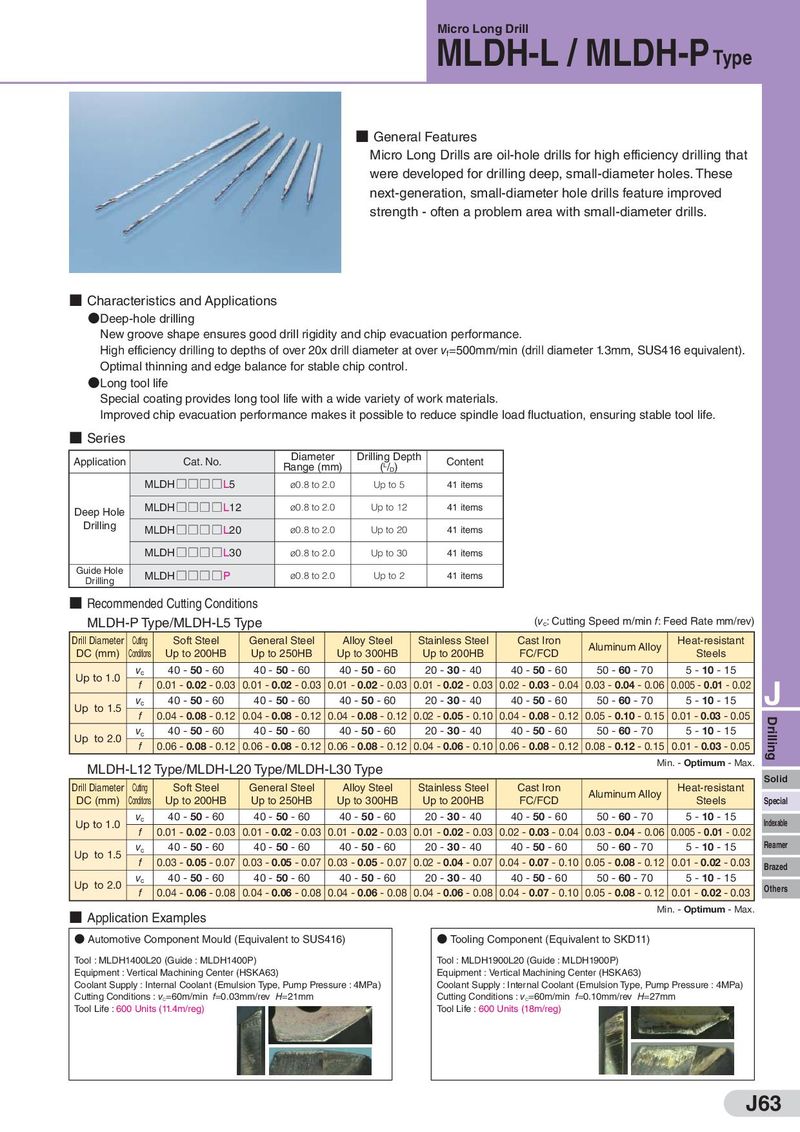

Micro Long Drill MLDH-L / MLDH-P Type ■ General Features Micro Long Drills are oil-hole drills for high efficiency drilling that were developed for drilling deep, small-diameter holes. These next-generation, small-diameter hole drills feature improved strength - often a problem area with small-diameter drills. ■ Characteristics and Applications ●Deep-hole drilling New groove shape ensures good drill rigidity and chip evacuation performance. High efficiency drilling to depths of over 20x drill diameter at over vf=500mm/min (drill diameter 1.3mm, SUS416 equivalent). Optimal thinning and edge balance for stable chip control. ●Long tool life Special coating provides long tool life with a wide variety of work materials. Improved chip evacuation performance makes it possible to reduce spindle load fluctuation, ensuring stable tool life. ■ Series Application Cat. No. Diameter Drilling Depth Content Range (mm) (L/D) MLDH □ □ □ □L5 ø0.8 to 2.0 Up to 5 41 items Deep Hole MLDH □ □ □ □ L12 ø0.8 to 2.0 Up to 12 41 items Drilling MLDH □ □ □ □ L20 ø0.8 to 2.0 Up to 20 41 items MLDH □ □ □ □ L30 ø0.8 to 2.0 Up to 30 41 items Guide Hole MLDH □ □ □ □P ø0.8 to 2.0 Up to 2 41 items Drilling ■ Recommended Cutting Conditions MLDH-P Type/MLDH-L5 Type (vc: Cutting Speed m/min f: Feed Rate mm/rev) Drill Diameter Cuting Soft Steel General Steel Alloy Steel Stainless Steel Cast Iron Aluminum Alloy Heat-resistant DC (mm) Conditions Up to 200HB Up to 250HB Up to 300HB Up to 200HB FC/FCD Steels Up to 1.0 vc 40 - 50 - 60 40 - 50 - 60 40 - 50 - 60 20 - 30 - 40 40 - 50 - 60 50 - 60 - 70 5 - 10 - 15 f 0.01 - 0.02 - 0.03 0.01 - 0.02 - 0.03 0.01 - 0.02 - 0.03 0.01 - 0.02 - 0.03 0.02 - 0.03 - 0.04 0.03 - 0.04 - 0.06 0.005 - 0.01 - 0.02 J Up to 1.5 vc 40 - 50 - 60 40 - 50 - 60 40 - 50 - 60 20 - 30 - 40 40 - 50 - 60 50 - 60 - 70 5 - 10 - 15 f 0.04 - 0.08 - 0.12 0.04 - 0.08 - 0.12 0.04 - 0.08 - 0.12 0.02 - 0.05 - 0.10 0.04 - 0.08 - 0.12 0.05 - 0.10 - 0.15 0.01 - 0.03 - 0.05 Drilling Up to 2.0 vc 40 - 50 - 60 40 - 50 - 60 40 - 50 - 60 20 - 30 - 40 40 - 50 - 60 50 - 60 - 70 5 - 10 - 15 f 0.06 - 0.08 - 0.12 0.06 - 0.08 - 0.12 0.06 - 0.08 - 0.12 0.04 - 0.06 - 0.10 0.06 - 0.08 - 0.12 0.08 - 0.12 - 0.15 0.01 - 0.03 - 0.05 MLDH-L12 Type/MLDH-L20 Type/MLDH-L30 Type Min. - Optimum - Max. Drill Diameter Cuting Soft Steel General Steel Alloy Steel Stainless Steel Cast Iron Heat-resistant Solid DC (mm) Conditions Up to 200HB Up to 250HB Up to 300HB Up to 200HB FC/FCD Aluminum Alloy Steels Special Up to 1.0 vc 40 - 50 - 60 40 - 50 - 60 40 - 50 - 60 20 - 30 - 40 40 - 50 - 60 50 - 60 - 70 5 - 10 - 15 Indexable f 0.01 - 0.02 - 0.03 0.01 - 0.02 - 0.03 0.01 - 0.02 - 0.03 0.01 - 0.02 - 0.03 0.02 - 0.03 - 0.04 0.03 - 0.04 - 0.06 0.005 - 0.01 - 0.02 vc 40 - 50 - 60 40 - 50 - 60 40 - 50 - 60 20 - 30 - 40 40 - 50 - 60 50 - 60 - 70 5 - 10 - 15 Reamer Up to 1.5 f 0.03 - 0.05 - 0.07 0.03 - 0.05 - 0.07 0.03 - 0.05 - 0.07 0.02 - 0.04 - 0.07 0.04 - 0.07 - 0.10 0.05 - 0.08 - 0.12 0.01 - 0.02 - 0.03 Brazed Up to 2.0 vc 40 - 50 - 60 40 - 50 - 60 40 - 50 - 60 20 - 30 - 40 40 - 50 - 60 50 - 60 - 70 5 - 10 - 15 f 0.04 - 0.06 - 0.08 0.04 - 0.06 - 0.08 0.04 - 0.06 - 0.08 0.04 - 0.06 - 0.08 0.04 - 0.07 - 0.10 0.05 - 0.08 - 0.12 0.01 - 0.02 - 0.03 Others ■ Application Examples Min. - Optimum - Max. ● Automotive Component Mould (Equivalent to SUS416) ● Tooling Component (Equivalent to SKD11) Tool : MLDH1400L20 (Guide : MLDH1400P) Tool : MLDH1900L20 (Guide : MLDH1900P) Equipment : Vertical Machining Center (HSKA63) Equipment : Vertical Machining Center (HSKA63) Coolant Supply : Internal Coolant (Emulsion Type, Pump Pressure : 4MPa) Coolant Supply : Internal Coolant (Emulsion Type, Pump Pressure : 4MPa) Cutting Conditions : vc=60m/min f=0.03mm/rev H=21mm Cutting Conditions : vc=60m/min f=0.10mm/rev H=27mm Tool Life : 600 Units (11.4m/reg) Tool Life : 600 Units (18m/reg) J63

Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Техническая информация Sumitomo

Техническая информация Sumitomo