Каталог Sumitomo сверла и развертки - страница 134

Навигация

- J001

- J1-001

- J1-002

- J1-003

- J1-004

- J1-005

- J1-006

- J1-007

- J1-008

- J1-009

- J1-010

- J1-011

- J1-012

- J1-013

- J1-014

- J1-015

- J1-016

- J1-017

- J1-018

- J1-019

- J1-020

- J1-021

- J1-022

- J002

- J003

- J004

- J005

- J006

- J007

- J008

- J009

- J010

- J011

- J012

- J013

- J014

- J015

- J016

- J017

- J018

- J019

- J020

- J021

- J022

- J023

- J024

- J025

- J026

- J027

- J028

- J029

- J030

- J031

- J032

- J033

- J034

- J035

- J036

- J037

- J038

- J039

- J040

- J041

- J042

- J043

- J044

- J045

- J046

- J047

- J048

- J049

- J050

- J051

- J052

- J053

- J054

- J055

- J056

- J057

- J058

- J059

- J060

- J061

- J062

- J063

- J064

- J065

- J066

- J067

- J068

- J069

- J070

- J071

- J072

- J073

- J074

- J075

- J076

- J077

- J078

- J079

- J080

- J081

- J082

- J083

- J084

- J085

- J086

- J087

- J088

- J089

- J090

- J091

- J092

- J093

- J094

- J095

- J096

- J097

- J098

- J099

- J100

- J101

- J102

- J103

- J104

- J105

- J106

- J107

- J108

- J109

- J110

- J111

- J112

- J113

- J114

- J115

- J116

- J117

- J118

- J119

- J120

- J121

- J122

- J123

- J124

- J125

- J126

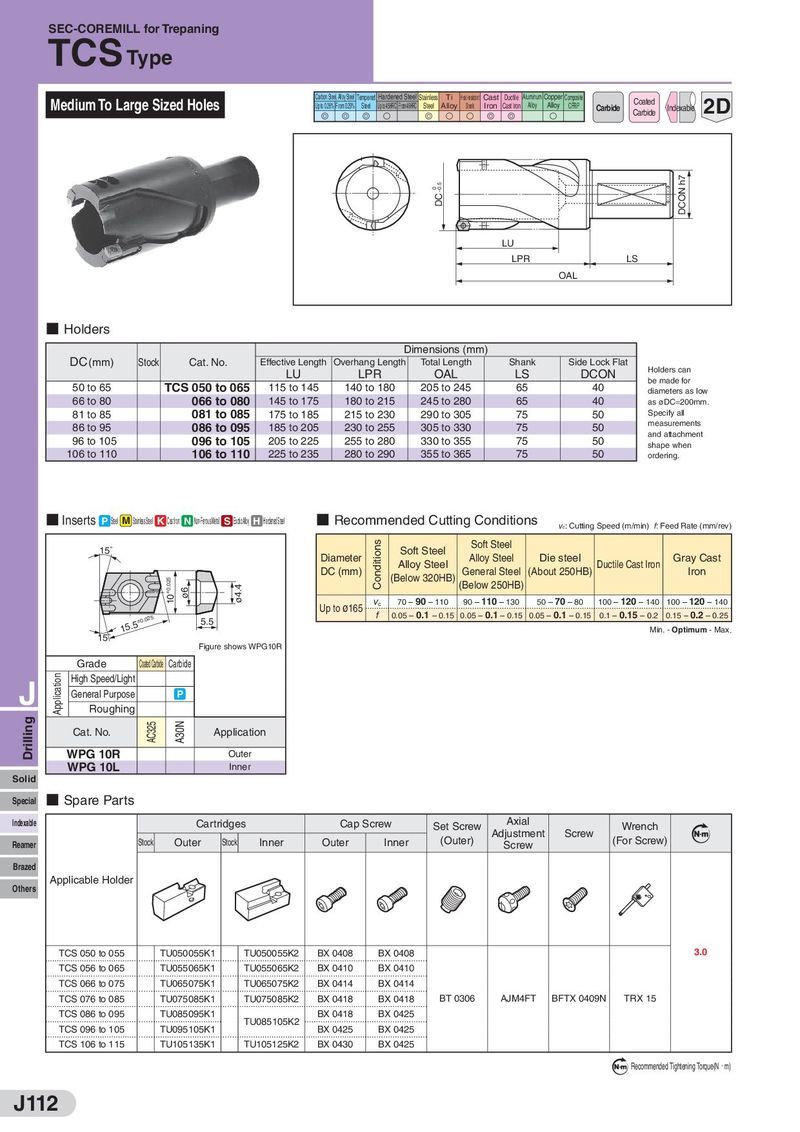

SEC-COREMILL for Trepaning TCS Type Medium To Large Sized Holes Carbon Steel, Aloy Steel Tempered Hardened Steel Stainless Ti Heat-resistant Cast Ductile Aluminum Copper Composite Coated 2D Up to 0.28% From 0.29% Steel Up to 45HRC From 46HRC Steel Alloy Steels Iron Cast Iron Alloy Alloy CFRP Carbide Carbide Indexable G G G S G S S G G S 0 –0.5 DCON h7 DC LU LPR LS OAL ■ Holders Dimensions (mm) DC (mm) Stock Cat. No. Effective Length Overhang Length Total Length Shank Side Lock Flat Holders can LU LPR OAL LS DCON be made for 50 to 65 TCS 050 to 065 115 to 145 140 to 180 205 to 245 65 40 diameters as low 66 to 80 066 to 080 145 to 175 180 to 215 245 to 280 65 40 as øDC=200mm. 81 to 85 081 to 085 175 to 185 215 to 230 290 to 305 75 50 Specify all 86 to 95 086 to 095 185 to 205 230 to 255 305 to 330 75 50 measurements 96 to 105 096 to 105 205 to 225 255 to 280 330 to 355 75 50 and attachment shape when 106 to 110 106 to 110 225 to 235 280 to 290 355 to 365 75 50 ordering. ■ Inserts P Steel M Stainless Steel K CastIron N Non-FerrousMetal S ExoticAloy H HardenedSteel ■ Recommended Cutting Conditions vc: Cutting Speed (m/min) f: Feed Rate (mm/rev) 15˚ Conditions Soft Steel Soft Steel Diameter Alloy Steel Alloy Steel Die steel Ductile Cast Iron Gray Cast DC (mm) (Below 320HB) General Steel (About 250HB) Iron 10 ±0.025 ø6 ø4.4 (Below 250HB) Up to ø165 vc 70 – 90 – 110 90 – 110 – 130 50 – 70 – 80 100 – 120 – 140 100 – 120 – 140 15.5±0.025 5.5 f 0.05 – 0.1 – 0.15 0.05 – 0.1 – 0.15 0.05 – 0.1 – 0.15 0.1 – 0.15 – 0.2 0.15 – 0.2 – 0.25 15˚ Min. - Optimum - Max. Figure shows WPG10R Grade Coated Carbide Carbide J Application High Speed/Light General Purpose P Roughing Drilling Cat. No. AC325 A30N Application WPG 10R Outer WPG 10L Inner Solid Special ■ Spare Parts Indexable Cartridges Cap Screw Set Screw Axial Wrench Stock Outer Stock Inner Outer Inner (Outer) Adjustment Screw (For Screw) Reamer Screw Brazed Others Applicable Holder TCS 050 to 055 TU050055K1 TU050055K2 BX 0408 BX 0408 3.0 TCS 056 to 065 TU055065K1 TU055065K2 BX 0410 BX 0410 TCS 066 to 075 TU065075K1 TU065075K2 BX 0414 BX 0414 TCS 076 to 085 TU075085K1 TU075085K2 BX 0418 BX 0418 BT 0306 AJM4FT BFTX 0409N TRX 15 TCS 086 to 095 TU085095K1 TU085105K2 BX 0418 BX 0425 TCS 096 to 105 TU095105K1 BX 0425 BX 0425 TCS 106 to 115 TU105135K1 TU105125K2 BX 0430 BX 0425 Recommended Tightening Torque(N・m) J112

Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Техническая информация Sumitomo

Техническая информация Sumitomo