Каталог Sumitomo сверла и развертки - страница 90

Навигация

- J001

- J1-001

- J1-002

- J1-003

- J1-004

- J1-005

- J1-006

- J1-007

- J1-008

- J1-009

- J1-010

- J1-011

- J1-012

- J1-013

- J1-014

- J1-015

- J1-016

- J1-017

- J1-018

- J1-019

- J1-020

- J1-021

- J1-022

- J002

- J003

- J004

- J005

- J006

- J007

- J008

- J009

- J010

- J011

- J012

- J013

- J014

- J015

- J016

- J017

- J018

- J019

- J020

- J021

- J022

- J023

- J024

- J025

- J026

- J027

- J028

- J029

- J030

- J031

- J032

- J033

- J034

- J035

- J036

- J037

- J038

- J039

- J040

- J041

- J042

- J043

- J044

- J045

- J046

- J047

- J048

- J049

- J050

- J051

- J052

- J053

- J054

- J055

- J056

- J057

- J058

- J059

- J060

- J061

- J062

- J063

- J064

- J065

- J066

- J067

- J068

- J069

- J070

- J071

- J072

- J073

- J074

- J075

- J076

- J077

- J078

- J079

- J080

- J081

- J082

- J083

- J084

- J085

- J086

- J087

- J088

- J089

- J090

- J091

- J092

- J093

- J094

- J095

- J096

- J097

- J098

- J099

- J100

- J101

- J102

- J103

- J104

- J105

- J106

- J107

- J108

- J109

- J110

- J111

- J112

- J113

- J114

- J115

- J116

- J117

- J118

- J119

- J120

- J121

- J122

- J123

- J124

- J125

- J126

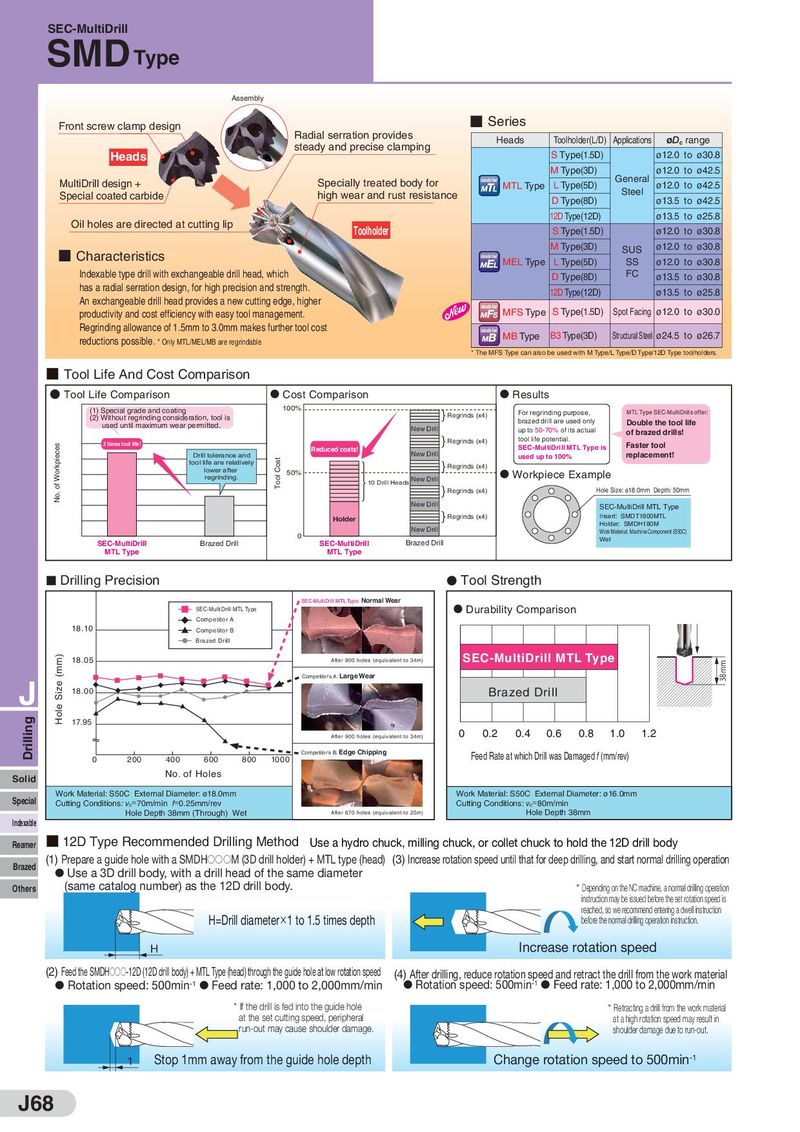

SEC-MultiDrill SMD Type Assembly Front screw clamp design ■ Series Radial serration provides Heads Toolholder(L/D) Applications øDc range Heads steady and precise clamping S Type(1.5D) ø12.0 to ø30.8 M Type(3D) General ø12.0 to ø42.5 MultiDrill design + Specially treated body for Indexable Head MTL Type L Type(5D) ø12.0 to ø42.5 Special coated carbide high wear and rust resistance D Type(8D) Steel ø13.5 to ø42.5 Oil holes are directed at cutting lip 12D Type(12D) ø13.5 to ø25.8 Toolholder S Type(1.5D) ø12.0 to ø30.8 ■ Characteristics M Type(3D) SUS ø12.0 to ø30.8 Indexable Head MEL Type L Type(5D) SS ø12.0 to ø30.8 Indexable type drill with exchangeable drill head, which D Type(8D) FC ø13.5 to ø30.8 has a radial serration design, for high precision and strength. 12D Type(12D) ø13.5 to ø25.8 An exchangeable drill head provides a new cutting edge, higher Indexable Head productivity and cost efficiency with easy tool management. MFS Type S Type(1.5D) Spot Facing ø12.0 to ø30.0 Regrinding allowance of 1.5mm to 3.0mm makes further tool cost Indexable Head MB Type B3 Type(3D) Structural Steel ø24.5 to ø26.7 reductions possible. * Only MTL/MEL/MB are regrindable * The MFS Type can also be used with M Type/L Type/D Type/12D Type toolholders. ■ Tool Life And Cost Comparison ● Tool Life Comparison D Cost Comparison D Results (1) Special grade and coating 100% For regrinding purpose, MTL Type SEC-MultiDrills offer: (2) Without regrinding consideration, tool is Regrinds (x4) brazed drill are used only used until maximum wear permitted. New Drill Double the tool life up to 50-70% of its actual of brazed drills! 2 times tool life! Regrinds (x4) tool life potential. Faster tool No. of Workpieces Reduced costs! New Drill SEC-MultiDrill MTL Type is Drill tolerance and Tool Cost used up to 100% replacement! tool life are relatively Regrinds (x4) lower after 50% D Workpiece Example regrinding. 10 Drill Heads New Drill Regrinds (x4) Hole Size: ø18.0mm Depth: 50mm New Drill SEC-MultiDrill MTL Type Holder Regrinds (x4) Insert: SMDT1800MTL New Drill Holder: SMDH180M 0 Work Material: Machine Component (S50C) SEC-MultiDrill Brazed Drill SEC-MultiDrill Brazed Drill Wet MTL Type MTL Type ■ Drilling Precision ● Tool Strength SEC-MultiDrill MTL Type: Normal Wear SEC-MultiDrill MTL Type D Durability Comparison Competitor A 18.10 Competitor B Brazed Drill Size (mm) 18.05 After 900 holes (equivalent to 34m) SEC-MultiDrill MTL Type 38mm Competitor's A: Large Wear J 18.00 Brazed Drill Drilling Hole 17.95 After 900 holes (equivalent to 34m) 0 0.2 0.4 0.6 0.8 1.0 1.2 Competitor's B: Edge Chipping Feed Rate at which Drill was Damaged f (mm/rev) 0 200 400 600 800 1000 Solid No. of Holes Special Work Material: S50C External Diameter: ø18.0mm Work Material: S50C External Diameter: ø16.0mm Cutting Conditions: vc=70m/min f=0.25mm/rev Cutting Conditions: vc=80m/min Hole Depth 38mm (Through) Wet After 670 holes (equivalent to 25m) Hole Depth 38mm Indexable Reamer ■ 12D Type Recommended Drilling Method Use a hydro chuck, milling chuck, or collet chuck to hold the 12D drill body Brazed (1) Prepare a guide hole with a SMDH○○○M (3D drill holder) + MTL type (head) (3) Increase rotation speed until that for deep drilling, and start normal drilling operation ● Use a 3D drill body, with a drill head of the same diameter Others (same catalog number) as the 12D drill body. * Depending on the NC machine, a normal drilling operation instruction may be issued before the set rotation speed is reached, so we recommend entering a dwell instruction H=Drill diameter×1 to 1.5 times depth before the normal drilling operation instruction. H Increase rotation speed (2) Feed the SMDH○○○-12D (12D drill body) + MTL Type (head) through the guide hole at low rotation speed (4) After drilling, reduce rotation speed and retract the drill from the work material ● Rotation speed: 500min-1 ● Feed rate: 1,000 to 2,000mm/min ● Rotation speed: 500min-1 ● Feed rate: 1,000 to 2,000mm/min * If the drill is fed into the guide hole * Retracting a drill from the work material at the set cutting speed, peripheral at a high rotation speed may result in run-out may cause shoulder damage. shoulder damage due to run-out. 1 Stop 1mm away from the guide hole depth Change rotation speed to 500min-1 J68

Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Техническая информация Sumitomo

Техническая информация Sumitomo