Каталог Sumitomo монолитные фрезы - страница 45

Навигация

- I_001

- I_1-001

- I_1-002

- I_1-003

- I_1-004

- I_1-005

- I_1-006

- I_002

- I_003

- I_004

- I_005

- I_006

- I_007

- I_008

- I_009

- I_010

- I_011

- I_012

- I_013

- I_014

- I_015

- I_016

- I_017

- I_018

- I_019

- I_020

- I_021

- I_022

- I_023

- I_024

- I_025

- I_026

- I_027

- I_028

- I_029

- I_030

- I_031

- I_032

- I_033

- I_034

- I_035

- I_036

- I_037

- I_038

- I_039

- I_040

- I_041

- I_042

- I_043

- I_044

- I_045

- I_046

- I_047

- I_048

- I_049

- I_050

- I_051

- I_052

- I_053

- I_054

- I_055

- I_056

- I_057

- I_058

- I_059

- I_060

- I_061

- I_062

- I_063

- I_064

- I_065

- I_066

- I_067

- I_068

- I_069

- I_070

- I_071

- I_072

- I_073

- I_074

- I_075

- I_076

- I_077

- I_078

- I_079

- I_080

- I_081

- I_082

- I_083

- I_084

- I_085

- I_086

- I_087

- I_088

- I_089

- I_090

- I_091

- I_092

- I_093

- I_094

- I_095

- I_096

- I_097

- I_098

- I_099

- I_100

- I_101

- I_102

- I_103

- I_104

- I_105

- I_106

- I_107

- I_108

- I_109

- I_110

- I_111

- I_112

- I_113

- I_114

- I_115

- I_116

- I_117

- I_118

- I_119

- I_120

- I_121

- I_122

- I_123

- I_124

- I_125

- I_126

- I_127

- I_128

- I_129

- I_130

- I_131

- I_132

- I_133

- I_134

- I_135

- I_136

- I_137

- I_138

- I_139

- I_140

- I_141

- I_142

- I_143

- I_144

- I_145

- I_146

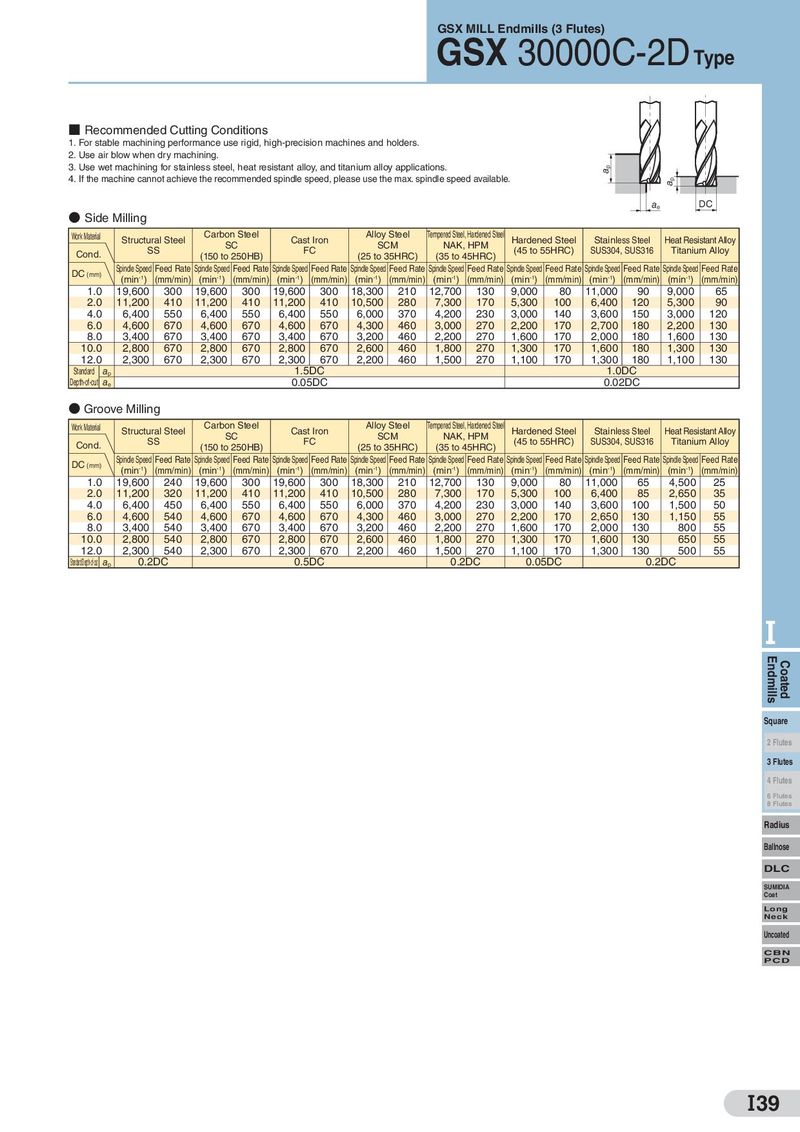

GSX MILL Endmills (3 Flutes) GSX 30000C-2D Type ■ Recommended Cutting Conditions 1. For stable machining performance use rigid, high-precision machines and holders. 2. Use air blow when dry machining. 3. Use wet machining for stainless steel, heat resistant alloy, and titanium alloy applications. ap 4. If the machine cannot achieve the recommended spindle speed, please use the max. spindle speed available. ap ae DC ● Side Milling Work Material Structural Steel Carbon Steel Cast Iron Alloy Steel Tempered Steel, Hardened Steel Hardened Steel Stainless Steel Heat Resistant Alloy SS SC FC SCM NAK, HPM (45 to 55HRC) SUS304, SUS316 Titanium Alloy Cond. (150 to 250HB) (25 to 35HRC) (35 to 45HRC) DC (mm) Spindle Speed Feed Rate Spindle Speed Feed Rate Spindle Speed Feed Rate Spindle Speed Feed Rate Spindle Speed Feed Rate Spindle Speed Feed Rate Spindle Speed Feed Rate Spindle Speed Feed Rate (min-1) (mm/min) (min-1) (mm/min) (min-1) (mm/min) (min-1) (mm/min) (min-1) (mm/min) (min-1) (mm/min) (min-1) (mm/min) (min-1) (mm/min) 1.0 19,600 300 19,600 300 19,600 300 18,300 210 12,700 130 9,000 80 11,000 90 9,000 65 2.0 11,200 410 11,200 410 11,200 410 10,500 280 7,300 170 5,300 100 6,400 120 5,300 90 4.0 6,400 550 6,400 550 6,400 550 6,000 370 4,200 230 3,000 140 3,600 150 3,000 120 6.0 4,600 670 4,600 670 4,600 670 4,300 460 3,000 270 2,200 170 2,700 180 2,200 130 8.0 3,400 670 3,400 670 3,400 670 3,200 460 2,200 270 1,600 170 2,000 180 1,600 130 10.0 2,800 670 2,800 670 2,800 670 2,600 460 1,800 270 1,300 170 1,600 180 1,300 130 12.0 2,300 670 2,300 670 2,300 670 2,200 460 1,500 270 1,100 170 1,300 180 1,100 130 Standard ap 1.5DC 1.0DC Depth-of-cut ae 0.05DC 0.02DC ● Groove Milling Work Material Structural Steel Carbon Steel Cast Iron Alloy Steel Tempered Steel, Hardened Steel Hardened Steel Stainless Steel Heat Resistant Alloy SS SC FC SCM NAK, HPM (45 to 55HRC) SUS304, SUS316 Titanium Alloy Cond. (150 to 250HB) (25 to 35HRC) (35 to 45HRC) DC (mm) Spindle Speed Feed Rate Spindle Speed Feed Rate Spindle Speed Feed Rate Spindle Speed Feed Rate Spindle Speed Feed Rate Spindle Speed Feed Rate Spindle Speed Feed Rate Spindle Speed Feed Rate (min-1) (mm/min) (min-1) (mm/min) (min-1) (mm/min) (min-1) (mm/min) (min-1) (mm/min) (min-1) (mm/min) (min-1) (mm/min) (min-1) (mm/min) 1.0 19,600 240 19,600 300 19,600 300 18,300 210 12,700 130 9,000 80 11,000 65 4,500 25 2.0 11,200 320 11,200 410 11,200 410 10,500 280 7,300 170 5,300 100 6,400 85 2,650 35 4.0 6,400 450 6,400 550 6,400 550 6,000 370 4,200 230 3,000 140 3,600 100 1,500 50 6.0 4,600 540 4,600 670 4,600 670 4,300 460 3,000 270 2,200 170 2,650 130 1,150 55 8.0 3,400 540 3,400 670 3,400 670 3,200 460 2,200 270 1,600 170 2,000 130 800 55 10.0 2,800 540 2,800 670 2,800 670 2,600 460 1,800 270 1,300 170 1,600 130 650 55 12.0 2,300 540 2,300 670 2,300 670 2,200 460 1,500 270 1,100 170 1,300 130 500 55 StandardDepth-of-cut ap 0.2DC 0.5DC 0.2DC 0.05DC 0.2DC I Endmills Coated Square 2 Flutes 3 Flutes 4 Flutes 6 Flutes 8 Flutes Radius Ballnose DLC SUMIDIA Coat Long Neck Uncoated CBN PCD I39

Каталог Sumitomo инструмент для отрезки

Каталог Sumitomo инструмент для отрезки Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Каталог Sumitomo сплавы и режимы

Каталог Sumitomo сплавы и режимы Каталог Sumitomo специальные торцевые фрезы

Каталог Sumitomo специальные торцевые фрезы Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами