Каталог Sumitomo монолитные фрезы - страница 18

Навигация

- I_001

- I_1-001

- I_1-002

- I_1-003

- I_1-004

- I_1-005

- I_1-006

- I_002

- I_003

- I_004

- I_005

- I_006

- I_007

- I_008

- I_009

- I_010

- I_011

- I_012

- I_013

- I_014

- I_015

- I_016

- I_017

- I_018

- I_019

- I_020

- I_021

- I_022

- I_023

- I_024

- I_025

- I_026

- I_027

- I_028

- I_029

- I_030

- I_031

- I_032

- I_033

- I_034

- I_035

- I_036

- I_037

- I_038

- I_039

- I_040

- I_041

- I_042

- I_043

- I_044

- I_045

- I_046

- I_047

- I_048

- I_049

- I_050

- I_051

- I_052

- I_053

- I_054

- I_055

- I_056

- I_057

- I_058

- I_059

- I_060

- I_061

- I_062

- I_063

- I_064

- I_065

- I_066

- I_067

- I_068

- I_069

- I_070

- I_071

- I_072

- I_073

- I_074

- I_075

- I_076

- I_077

- I_078

- I_079

- I_080

- I_081

- I_082

- I_083

- I_084

- I_085

- I_086

- I_087

- I_088

- I_089

- I_090

- I_091

- I_092

- I_093

- I_094

- I_095

- I_096

- I_097

- I_098

- I_099

- I_100

- I_101

- I_102

- I_103

- I_104

- I_105

- I_106

- I_107

- I_108

- I_109

- I_110

- I_111

- I_112

- I_113

- I_114

- I_115

- I_116

- I_117

- I_118

- I_119

- I_120

- I_121

- I_122

- I_123

- I_124

- I_125

- I_126

- I_127

- I_128

- I_129

- I_130

- I_131

- I_132

- I_133

- I_134

- I_135

- I_136

- I_137

- I_138

- I_139

- I_140

- I_141

- I_142

- I_143

- I_144

- I_145

- I_146

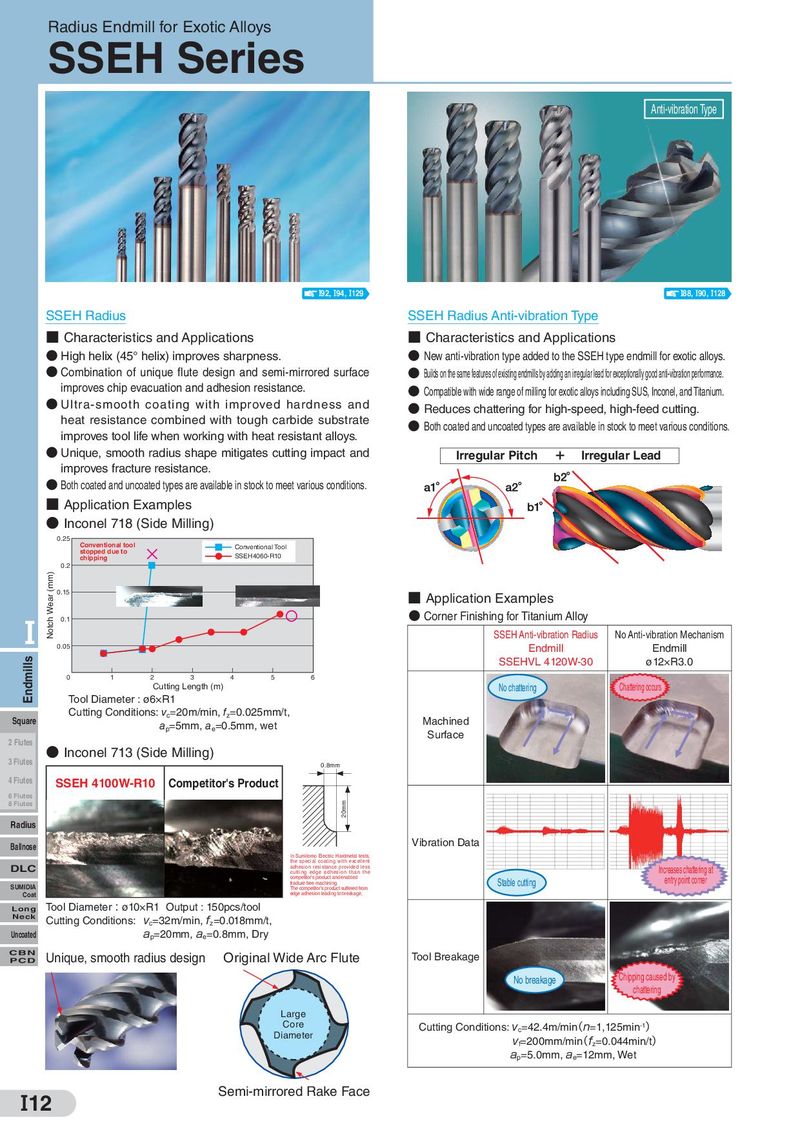

Radius Endmill for Exotic Alloys SSEH Series Anti-vibration Type I92, I94, I129 I88, I90, I128 SSEH Radius SSEH Radius Anti-vibration Type ■ Characteristics and Applications ■ Characteristics and Applications ● High helix (45° helix) improves sharpness. ● New anti-vibration type added to the SSEH type endmill for exotic alloys. ● Combination of unique flute design and semi-mirrored surface ● Builds on the same features of existing endmils by adding an irregular lead for exceptionaly good anti-vibration performance. improves chip evacuation and adhesion resistance. ● Compatible with wide range of milling for exotic alloys including SUS, Inconel, and Titanium. ● Ultra-smooth coating with improved hardness and ● Reduces chattering for high-speed, high-feed cutting. heat resistance combined with tough carbide substrate ● Both coated and uncoated types are available in stock to meet various conditions. improves tool life when working with heat resistant alloys. ● Unique, smooth radius shape mitigates cutting impact and Irregular Pitch + Irregular Lead improves fracture resistance. ● Both coated and uncoated types are available in stock to meet various conditions. ■ Application Examples ● Inconel 718 (Side Milling) 0.25 Conventional tool Conventional Tool stopped due to SSEH4060-R10 chipping 0.2 Notch Wear (mm) 0.15 ■ Application Examples I 0.1 ● Corner Finishing for Titanium Alloy SSEH Anti-vibration Radius No Anti-vibration Mechanism 0.05 Endmill Endmill Endmills SSEHVL 4120W-30 ø12×R3.0 0 1 2 3 4 5 6 Cutting Length (m) No chattering Chattering occurs Tool Diameter : ø6×R1 Square Cutting Conditions: vc=20m/min, fz=0.025mm/t, Machined ap=5mm, ae=0.5mm, wet Surface 2 Flutes ● 3 Flutes Inconel 713 (Side Milling) 0.8mm 4 Flutes SSEH 4100W-R10 Competitor's Product 6 Flutes 8 Flutes 20mm Radius Ballnose Vibration Data In Sumitomo Electric Hardmetal tests, the special coating with excellent DLC adhesion resistance provided less Increases chattering at cutting edge adhesion than the competitor's product and enabled Stable cutting entry point corner SUMIDIA fracture free machining. The competitor's product suffered from Coat edge adhesion leading to breakage. Long Tool Diameter : ø10×R1 Output : 150pcs/tool Neck Cutting Conditions: c=32m/min, z=0.018mm/t, Uncoated p=20mm, e=0.8mm, Dry CBN Unique, smooth radius design Original Wide Arc Flute Tool Breakage PCD No breakage Chipping caused by chattering Large Core Cutting Conditions: c=42.4m/min( =1,125min-1) Diameter f=200mm/min( z=0.044min/t) p=5.0mm, e=12mm, Wet I12 Semi-mirrored Rake Face

Каталог Sumitomo инструмент для отрезки

Каталог Sumitomo инструмент для отрезки Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Каталог Sumitomo сплавы и режимы

Каталог Sumitomo сплавы и режимы Каталог Sumitomo специальные торцевые фрезы

Каталог Sumitomo специальные торцевые фрезы Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами