Каталог Sumitomo монолитные фрезы - страница 10

Навигация

- I_001

- I_1-001

- I_1-002

- I_1-003

- I_1-004

- I_1-005

- I_1-006

- I_002

- I_003

- I_004

- I_005

- I_006

- I_007

- I_008

- I_009

- I_010

- I_011

- I_012

- I_013

- I_014

- I_015

- I_016

- I_017

- I_018

- I_019

- I_020

- I_021

- I_022

- I_023

- I_024

- I_025

- I_026

- I_027

- I_028

- I_029

- I_030

- I_031

- I_032

- I_033

- I_034

- I_035

- I_036

- I_037

- I_038

- I_039

- I_040

- I_041

- I_042

- I_043

- I_044

- I_045

- I_046

- I_047

- I_048

- I_049

- I_050

- I_051

- I_052

- I_053

- I_054

- I_055

- I_056

- I_057

- I_058

- I_059

- I_060

- I_061

- I_062

- I_063

- I_064

- I_065

- I_066

- I_067

- I_068

- I_069

- I_070

- I_071

- I_072

- I_073

- I_074

- I_075

- I_076

- I_077

- I_078

- I_079

- I_080

- I_081

- I_082

- I_083

- I_084

- I_085

- I_086

- I_087

- I_088

- I_089

- I_090

- I_091

- I_092

- I_093

- I_094

- I_095

- I_096

- I_097

- I_098

- I_099

- I_100

- I_101

- I_102

- I_103

- I_104

- I_105

- I_106

- I_107

- I_108

- I_109

- I_110

- I_111

- I_112

- I_113

- I_114

- I_115

- I_116

- I_117

- I_118

- I_119

- I_120

- I_121

- I_122

- I_123

- I_124

- I_125

- I_126

- I_127

- I_128

- I_129

- I_130

- I_131

- I_132

- I_133

- I_134

- I_135

- I_136

- I_137

- I_138

- I_139

- I_140

- I_141

- I_142

- I_143

- I_144

- I_145

- I_146

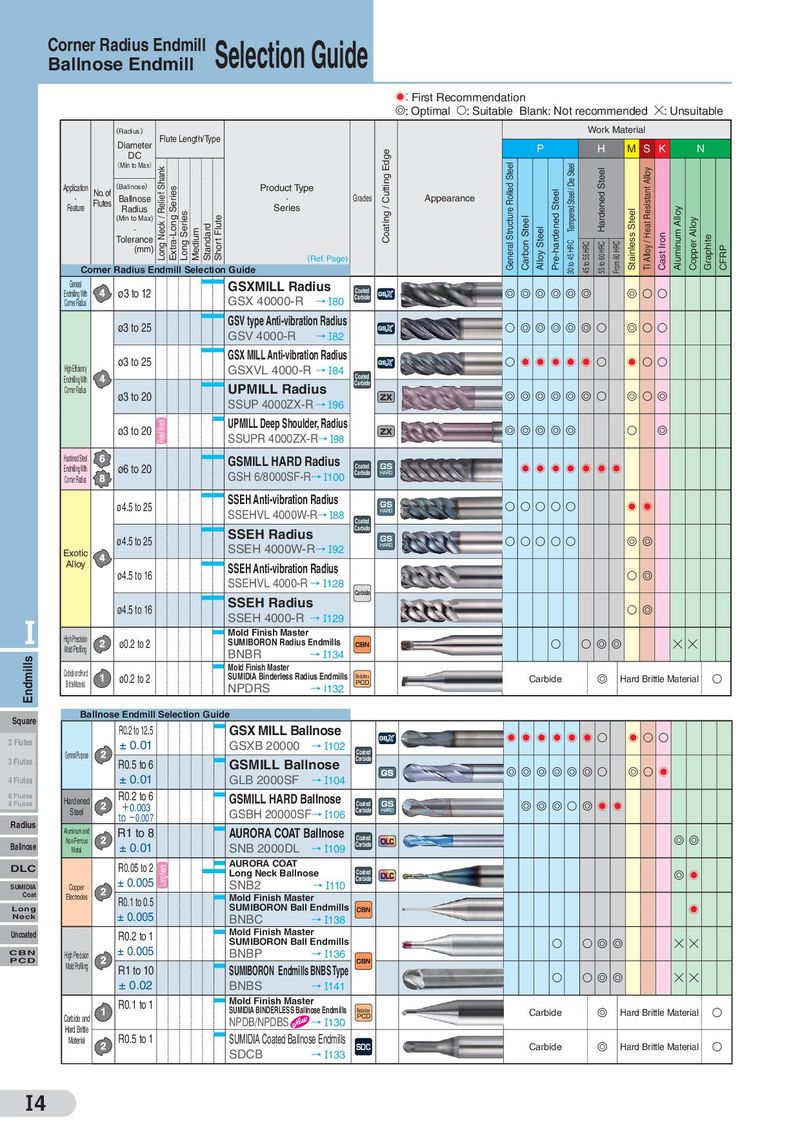

Selection Guide Corner Radius Endmill Ballnose Endmill A:First Recommendation G: Optimal S: Suitable Blank: Not recommended H: Unsuitable (Radius) Work Material Diameter Flute Length/Type DC Coating / Cutting Edge P H M S K N (Min to Max) Long Neck / Relief Shank General Structure Rolled Steel Tempered Steel / Die Steel Hardened Steel Ti Alloy / Heat Resistant Alloy Application No. of (Ballnose) Extra-Long Series Product Type Pre-hardened Steel · Flutes Ballnose · Grades Appearance Feature Radius Long Series Series Stainless Steel Aluminum Alloy (Min to Max) Short Flute Carbon Steel Copper Alloy · Medium Standard Alloy Steel Cast Iron Tolerance 30 to 45 HRC 45 to 55 HRC 55 to 60 HRC From 60 HRC Graphite (mm) CFRP (Ref. Page) Corner Radius Endmill Selection Guide General ø3 to 12 GSXMILL Radius Coated Endmil ing With GSX 40000-R → I80 Carbide G G G G G G G S S Corner Radius ø3 to 25 GSV type Anti-vibration Radius S G G G G G S G S S GSV 4000-R → I82 ø3 to 25 GSX MILL Anti-vibration Radius S A A A A A S A S S High Eficiency GSXVL 4000-R → I84 Endmil ing With Coated Corner Radius UPMILL Radius Carbide ø3 to 20 SSUP 4000ZX-R → I96 G G G G G G S G S G ø3 to 20 Relief Shank UPMILL Deep Shoulder, Radius G G G G G S G SSUPR 4000ZX-R→ I98 Hardened Steel GSMILL HARD Radius Endmil ing With ø6 to 20 Coated GS A A A A A A A GSH 6/8000SF-R→ I100 Carbide HARD Corner Radius ø4.5 to 25 SSEH Anti-vibration Radius GS S S S S S AA SSEHVL 4000W-R→ I88 HARD Coated SSEH Radius Carbide ø4.5 to 25 GS S S S S S GG SSEH 4000W-R→ I92 HARD Exotic Alloy SSEH Anti-vibration Radius ø4.5 to 16 SSEHVL 4000-R → I128 SG Carbide ø4.5 to 16 SSEH Radius SG I SSEH 4000-R → I129 High Precision Mold Finish Master Mold Profiling ø0.2 to 2 SUMIBORON Radius Endmills S S G G HH Endmills BNBR → I134 Carbide and Hard Mold Finish Master ø0.2 to 2 SUMIDIA Binderless Radius Endmills Binderless Carbide G Hard Brittle Material S Brit le Material NPDRS → I132 PCD Square Ballnose Endmill Selection Guide R0.2 to 12.5 GSX MILL Ballnose A A A A A A S ASS 2 Flutes ± 0.01 GSXB 20000 → I102 General Purpose Coated 3 Flutes R0.5 to 6 GSMILL Ballnose Carbide 4 Flutes ± 0.01 GLB 2000SF → I104 G G G G G G S GSA 6 Flutes Hardened R0.2 to 6 GSMILL HARD Ballnose 8 Flutes +0.003 Coated GS G G G S G A A Steel GSBH 20000SF→ I106 Carbide HARD Radius to −0.007 Aluminum and R1 to 8 AURORA COAT Ballnose Coated Ballnose Non-Ferrous ± 0.01 SNB 2000DL → I109 Carbide GG Metal DLC R0.05 to 2 Long Neck AURORA COAT Long Neck Ballnose Coated GA ± 0.005 SNB2 → I110 Carbide SUMIDIA Copper Coat Electrodes R0.1 to 0.5 Mold Finish Master Long ± 0.005 SUMIBORON Ball Endmills A Neck BNBC → I138 Uncoated R0.2 to 1 Mold Finish Master ± 0.005 SUMIBORON Ball Endmills S S G G HH CBN High Precision BNBP → I136 PCD Mold Profiling R1 to 10 SUMIBORON Endmills BNBS Type S S G G HH ± 0.02 BNBS → I141 R0.1 to 1 Mold Finish Master SUMIDIA BINDERLESS Ballnose Endmills Binderless Carbide G Hard Brittle Material S Carbide and NPDB/NPDBS → I130 PCD Hard Brittle SUMIDIA Coated Ballnose Endmills Material R0.5 to 1 SDC Carbide G Hard Brittle Material S SDCB → I133 I4

Каталог Sumitomo инструмент для отрезки

Каталог Sumitomo инструмент для отрезки Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Каталог Sumitomo сплавы и режимы

Каталог Sumitomo сплавы и режимы Каталог Sumitomo специальные торцевые фрезы

Каталог Sumitomo специальные торцевые фрезы Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами