Каталог Sumitomo монолитные фрезы - страница 12

Навигация

- I_001

- I_1-001

- I_1-002

- I_1-003

- I_1-004

- I_1-005

- I_1-006

- I_002

- I_003

- I_004

- I_005

- I_006

- I_007

- I_008

- I_009

- I_010

- I_011

- I_012

- I_013

- I_014

- I_015

- I_016

- I_017

- I_018

- I_019

- I_020

- I_021

- I_022

- I_023

- I_024

- I_025

- I_026

- I_027

- I_028

- I_029

- I_030

- I_031

- I_032

- I_033

- I_034

- I_035

- I_036

- I_037

- I_038

- I_039

- I_040

- I_041

- I_042

- I_043

- I_044

- I_045

- I_046

- I_047

- I_048

- I_049

- I_050

- I_051

- I_052

- I_053

- I_054

- I_055

- I_056

- I_057

- I_058

- I_059

- I_060

- I_061

- I_062

- I_063

- I_064

- I_065

- I_066

- I_067

- I_068

- I_069

- I_070

- I_071

- I_072

- I_073

- I_074

- I_075

- I_076

- I_077

- I_078

- I_079

- I_080

- I_081

- I_082

- I_083

- I_084

- I_085

- I_086

- I_087

- I_088

- I_089

- I_090

- I_091

- I_092

- I_093

- I_094

- I_095

- I_096

- I_097

- I_098

- I_099

- I_100

- I_101

- I_102

- I_103

- I_104

- I_105

- I_106

- I_107

- I_108

- I_109

- I_110

- I_111

- I_112

- I_113

- I_114

- I_115

- I_116

- I_117

- I_118

- I_119

- I_120

- I_121

- I_122

- I_123

- I_124

- I_125

- I_126

- I_127

- I_128

- I_129

- I_130

- I_131

- I_132

- I_133

- I_134

- I_135

- I_136

- I_137

- I_138

- I_139

- I_140

- I_141

- I_142

- I_143

- I_144

- I_145

- I_146

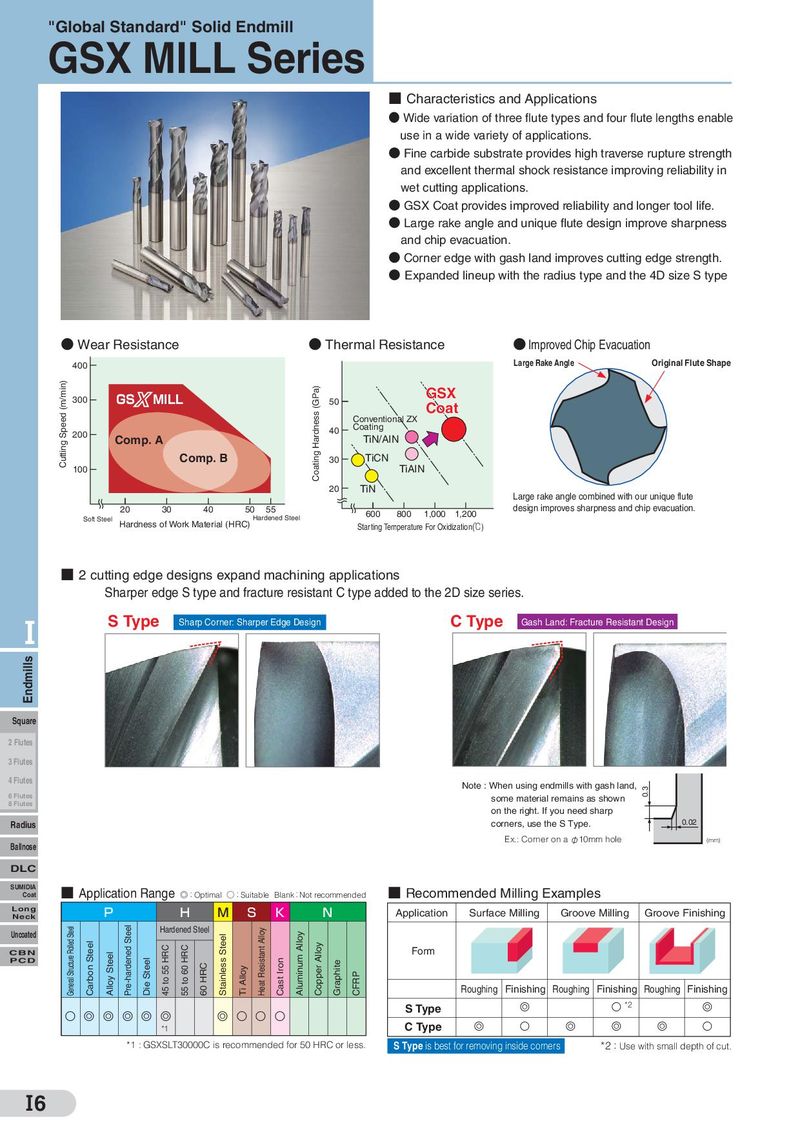

"Global Standard" Solid Endmill GSX MILL Series ■ Characteristics and Applications ● Wide variation of three flute types and four flute lengths enable use in a wide variety of applications. ● Fine carbide substrate provides high traverse rupture strength and excellent thermal shock resistance improving reliability in wet cutting applications. ● GSX Coat provides improved reliability and longer tool life. ● Large rake angle and unique flute design improve sharpness and chip evacuation. ● Corner edge with gash land improves cutting edge strength. ● Expanded lineup with the radius type and the 4D size S type ● Wear Resistance ● Thermal Resistance ● Improved Chip Evacuation 400 Large Rake Angle Original Flute Shape Cutting Speed (m/min) 300 GSX MILL Coating Hardness (GPa) 50 GSX Conventional ZX Coat 200 40 Coating Comp. A TiN/AIN Comp. B 30 TiCN 100 TiAIN 20 TiN Large rake angle combined with our unique flute 20 30 40 50 55 600 800 1,000 1,200 design improves sharpness and chip evacuation. Soft Steel Hardness of Work Material (HRC) Hardened Steel Starting Temperature For Oxidization(℃) ■ 2 cutting edge designs expand machining applications Sharper edge S type and fracture resistant C type added to the 2D size series. I S Type Sharp Corner: Sharper Edge Design C Type Gash Land: Fracture Resistant Design Endmills Square 2 Flutes 3 Flutes 4 Flutes Note : When using endmills with gash land, 6 Flutes some material remains as shown 0.3 8 Flutes on the right. If you need sharp Radius corners, use the S Type. 0.02 Ballnose Ex.: Corner on a φ10mm hole (mm) DLC SUMIDIA ■ Application Range ■ Recommended Milling Examples Coat ◎:Optimal ○:Suitable Blank:Not recommended Long P H M S K N Application Surface Milling Groove Milling Groove Finishing Neck Uncoated General Structure Rolled Steel Pre-hardened Steel Hardened Steel Stainless Steel Heat Resistant Alloy Aluminum Alloy CBN Carbon Steel Alloy Steel 45 to 55 HRC 55 to 60 HRC Copper Alloy Form PCD Die Steel 60 HRC Cast Iron Graphite Ti Alloy CFRP Roughing Finishing Roughing Finishing Roughing Finishing S G G G G G G S S S S Type G S *2 G *1 C Type G S G G G S *1 : GSXSLT30000C is recommended for 50 HRC or less. S Type is best for removing inside corners *2 : Use with small depth of cut. I6

Каталог Sumitomo инструмент для отрезки

Каталог Sumitomo инструмент для отрезки Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Каталог Sumitomo сплавы и режимы

Каталог Sumitomo сплавы и режимы Каталог Sumitomo специальные торцевые фрезы

Каталог Sumitomo специальные торцевые фрезы Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами