Каталог Sumitomo монолитные фрезы - страница 138

Навигация

- I_001

- I_1-001

- I_1-002

- I_1-003

- I_1-004

- I_1-005

- I_1-006

- I_002

- I_003

- I_004

- I_005

- I_006

- I_007

- I_008

- I_009

- I_010

- I_011

- I_012

- I_013

- I_014

- I_015

- I_016

- I_017

- I_018

- I_019

- I_020

- I_021

- I_022

- I_023

- I_024

- I_025

- I_026

- I_027

- I_028

- I_029

- I_030

- I_031

- I_032

- I_033

- I_034

- I_035

- I_036

- I_037

- I_038

- I_039

- I_040

- I_041

- I_042

- I_043

- I_044

- I_045

- I_046

- I_047

- I_048

- I_049

- I_050

- I_051

- I_052

- I_053

- I_054

- I_055

- I_056

- I_057

- I_058

- I_059

- I_060

- I_061

- I_062

- I_063

- I_064

- I_065

- I_066

- I_067

- I_068

- I_069

- I_070

- I_071

- I_072

- I_073

- I_074

- I_075

- I_076

- I_077

- I_078

- I_079

- I_080

- I_081

- I_082

- I_083

- I_084

- I_085

- I_086

- I_087

- I_088

- I_089

- I_090

- I_091

- I_092

- I_093

- I_094

- I_095

- I_096

- I_097

- I_098

- I_099

- I_100

- I_101

- I_102

- I_103

- I_104

- I_105

- I_106

- I_107

- I_108

- I_109

- I_110

- I_111

- I_112

- I_113

- I_114

- I_115

- I_116

- I_117

- I_118

- I_119

- I_120

- I_121

- I_122

- I_123

- I_124

- I_125

- I_126

- I_127

- I_128

- I_129

- I_130

- I_131

- I_132

- I_133

- I_134

- I_135

- I_136

- I_137

- I_138

- I_139

- I_140

- I_141

- I_142

- I_143

- I_144

- I_145

- I_146

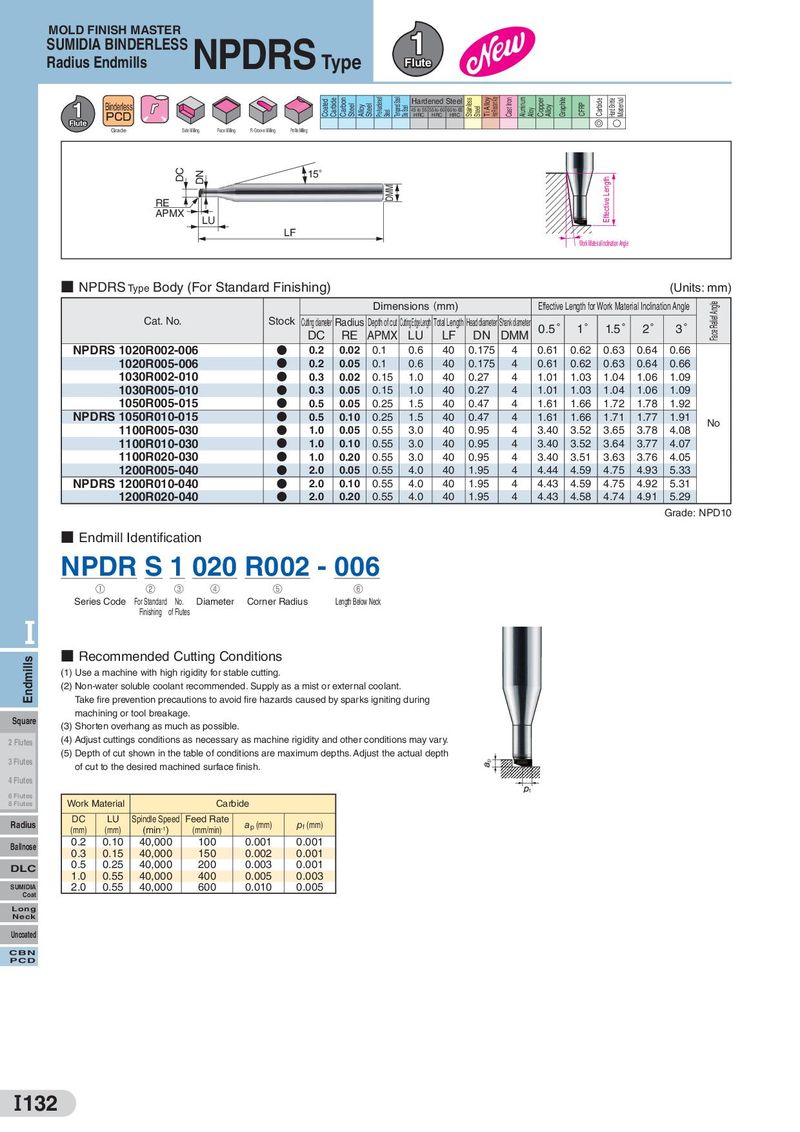

MOLD FINISH MASTER 1 NPDRS SUMIDIA BINDERLESS Type Radius Endmills Flute 1 Binderless Coated Carbide Carbon Steel Alloy Steel Pre-hardened Tempered Steel Hardened Steel Stainless Ti Alloy Heat Resistant A loy Cast Iron Aluminum Copper Alloy Graphite CFRP Carbide Hard Brittle Material Steel Die Steel 45 to 55 55 to 60 60 to 65 Steel Alloy HRC HRC HRC PCD Flute G S Grade Side Milling Face Milling R-Groove Milling Profile Milling DC DN 15° Effective Length RE DMM APMX LU LF Work Material Inclination Angle ■ NPDRS Type Body (For Standard Finishing) (Units: mm) Dimensions (mm) Effective Length for Work Material Inclination Angle Face Relief Angle Cat. No. Stock Cuting diameter Radius Depth of cut CutingEdgeLength Total Length Head diameter Shank diameter 0.5 1 1.5 2 3 DC RE APMX LU LF DN DMM NPDRS 1020R002-006 D 0.2 0.02 0.1 0.6 40 0.175 4 0.61 0.62 0.63 0.64 0.66 1020R005-006 D 0.2 0.05 0.1 0.6 40 0.175 4 0.61 0.62 0.63 0.64 0.66 1030R002-010 D 0.3 0.02 0.15 1.0 40 0.27 4 1.01 1.03 1.04 1.06 1.09 1030R005-010 D 0.3 0.05 0.15 1.0 40 0.27 4 1.01 1.03 1.04 1.06 1.09 1050R005-015 D 0.5 0.05 0.25 1.5 40 0.47 4 1.61 1.66 1.72 1.78 1.92 NPDRS 1050R010-015 D 0.5 0.10 0.25 1.5 40 0.47 4 1.61 1.66 1.71 1.77 1.91 No 1100R005-030 D 1.0 0.05 0.55 3.0 40 0.95 4 3.40 3.52 3.65 3.78 4.08 1100R010-030 D 1.0 0.10 0.55 3.0 40 0.95 4 3.40 3.52 3.64 3.77 4.07 1100R020-030 D 1.0 0.20 0.55 3.0 40 0.95 4 3.40 3.51 3.63 3.76 4.05 1200R005-040 D 2.0 0.05 0.55 4.0 40 1.95 4 4.44 4.59 4.75 4.93 5.33 NPDRS 1200R010-040 D 2.0 0.10 0.55 4.0 40 1.95 4 4.43 4.59 4.75 4.92 5.31 1200R020-040 D 2.0 0.20 0.55 4.0 40 1.95 4 4.43 4.58 4.74 4.91 5.29 Grade: NPD10 ■ Endmill Identification NPDR S 1 020 R002 - 006 ① ② ③ ④ ⑤ ⑥ Series Code For Standard No. Diameter Corner Radius Length Below Neck Finishing of Flutes I Endmills ■ Recommended Cutting Conditions (1) Use a machine with high rigidity for stable cutting. (2) Non-water soluble coolant recommended. Supply as a mist or external coolant. Take fire prevention precautions to avoid fire hazards caused by sparks igniting during Square machining or tool breakage. (3) Shorten overhang as much as possible. 2 Flutes (4) Adjust cuttings conditions as necessary as machine rigidity and other conditions may vary. 3 Flutes (5) Depth of cut shown in the table of conditions are maximum depths. Adjust the actual depth p of cut to the desired machined surface finish. 4 Flutes f 6 Flutes 8 Flutes Work Material Carbide Radius DC LU Spindle Speed Feed Rate ap (mm) pf (mm) (mm) (mm) (min-1) (mm/min) Ballnose 0.2 0.10 40,000 100 0.001 0.001 0.3 0.15 40,000 150 0.002 0.001 DLC 0.5 0.25 40,000 200 0.003 0.001 1.0 0.55 40,000 400 0.005 0.003 SUMIDIA 2.0 0.55 40,000 600 0.010 0.005 Coat Long Neck Uncoated CBN PCD I132

Каталог Sumitomo инструмент для отрезки

Каталог Sumitomo инструмент для отрезки Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Каталог Sumitomo сплавы и режимы

Каталог Sumitomo сплавы и режимы Каталог Sumitomo специальные торцевые фрезы

Каталог Sumitomo специальные торцевые фрезы Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами