Каталог Sumitomo монолитные фрезы - страница 24

Навигация

- I_001

- I_1-001

- I_1-002

- I_1-003

- I_1-004

- I_1-005

- I_1-006

- I_002

- I_003

- I_004

- I_005

- I_006

- I_007

- I_008

- I_009

- I_010

- I_011

- I_012

- I_013

- I_014

- I_015

- I_016

- I_017

- I_018

- I_019

- I_020

- I_021

- I_022

- I_023

- I_024

- I_025

- I_026

- I_027

- I_028

- I_029

- I_030

- I_031

- I_032

- I_033

- I_034

- I_035

- I_036

- I_037

- I_038

- I_039

- I_040

- I_041

- I_042

- I_043

- I_044

- I_045

- I_046

- I_047

- I_048

- I_049

- I_050

- I_051

- I_052

- I_053

- I_054

- I_055

- I_056

- I_057

- I_058

- I_059

- I_060

- I_061

- I_062

- I_063

- I_064

- I_065

- I_066

- I_067

- I_068

- I_069

- I_070

- I_071

- I_072

- I_073

- I_074

- I_075

- I_076

- I_077

- I_078

- I_079

- I_080

- I_081

- I_082

- I_083

- I_084

- I_085

- I_086

- I_087

- I_088

- I_089

- I_090

- I_091

- I_092

- I_093

- I_094

- I_095

- I_096

- I_097

- I_098

- I_099

- I_100

- I_101

- I_102

- I_103

- I_104

- I_105

- I_106

- I_107

- I_108

- I_109

- I_110

- I_111

- I_112

- I_113

- I_114

- I_115

- I_116

- I_117

- I_118

- I_119

- I_120

- I_121

- I_122

- I_123

- I_124

- I_125

- I_126

- I_127

- I_128

- I_129

- I_130

- I_131

- I_132

- I_133

- I_134

- I_135

- I_136

- I_137

- I_138

- I_139

- I_140

- I_141

- I_142

- I_143

- I_144

- I_145

- I_146

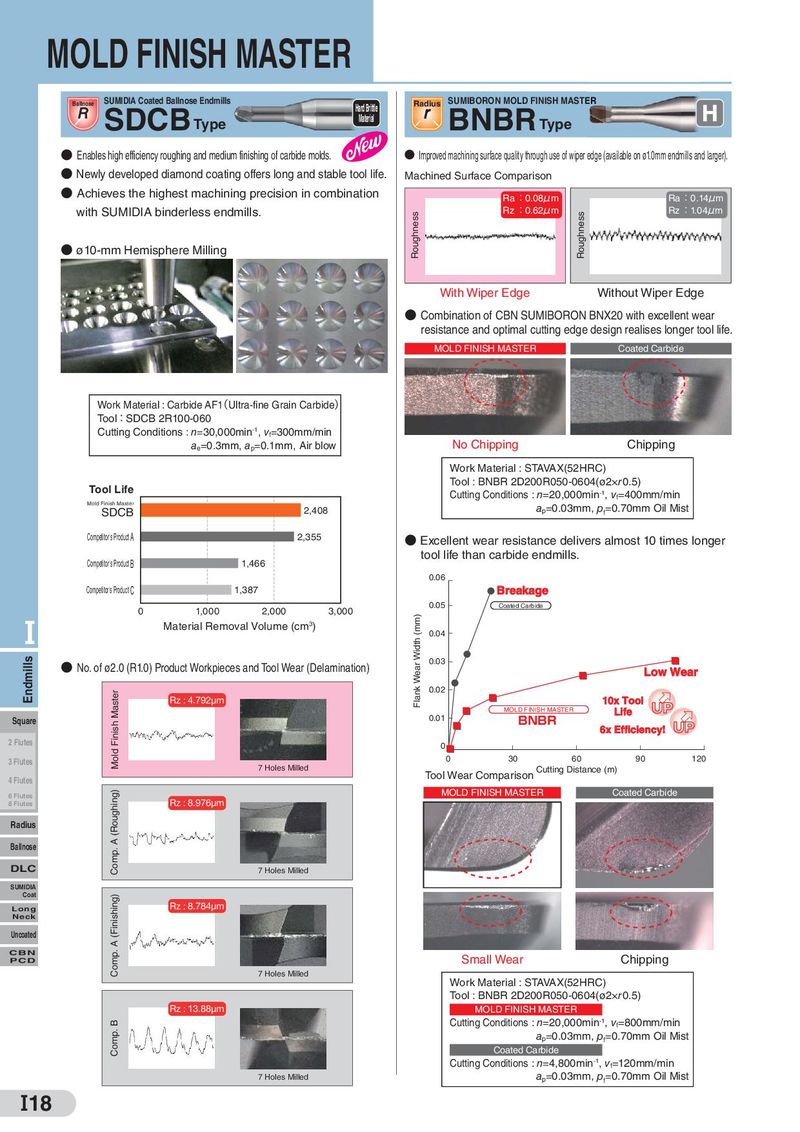

MOLD FINISH MASTER Ballnose SUMIDIA Coated Ballnose Endmills Hard Brittle Radius SUMIBORON MOLD FINISH MASTER R SDCB Type Material r BNBR Type ● Enables high efficiency roughing and medium finishing of carbide molds. D Improved machining surface quality through use of wiper edge (available on ø1.0mm endmills and larger). ● Newly developed diamond coating offers long and stable tool life. Machined Surface Comparison ● Achieves the highest machining precision in combination Ra :0.08μm Ra :0.14μm with SUMIDIA binderless endmills. Roughness Rz :0.62μm Roughness Rz :1.04μm ● ø10-mm Hemisphere Milling With Wiper Edge Without Wiper Edge ● Combination of CBN SUMIBORON BNX20 with excellent wear resistance and optimal cutting edge design realises longer tool life. MOLD FINISH MASTER Coated Carbide Work Material : Carbide AF1(Ultra-fine Grain Carbide) Tool:SDCB 2R100-060 Cutting Conditions : n=30,000min-1, vf=300mm/min ae=0.3mm, ap=0.1mm, Air blow No Chipping Chipping Work Material : STAVAX(52HRC) Tool Life Tool : BNBR 2D200R050-0604(ø2×r 0.5) Cutting Conditions : n=20,000min-1, vf=400mm/min Mold Finish Master ap=0.03mm, pf=0.70mm Oil Mist SDCB 2,408 Competitor's Product A 2,355 ● Excellent wear resistance delivers almost 10 times longer Competitor's Product B 1,466 tool life than carbide endmills. 0.06 Competitor's Product C 1,387 Breakage 0 1,000 2,000 3,000 0.05 Coated Carbide I Material Removal Volume (cm3) (mm) 0.04 Endmills ● No. of ø2.0 (R1.0) Product Workpieces and Tool Wear (Delamination) Flank Wear Width 0.03 Low Wear Master 0.02 Rz : 4.792μm 61x0xLEifTffeiocoiel ncUy!P⇨UP⇨ MOLD FINISH MASTER Square Finish 0.01 BNBR 2 Flutes 0 3 Flutes Mold 0 30 60 90 120 7 Holes Milled Tool Wear Comparison Cutting Distance (m) 4 Flutes 6 Flutes Comp. A (Roughing) MOLD FINISH MASTER Coated Carbide 8 Flutes Rz : 8.976μm Radius Ballnose DLC 7 Holes Milled SUMIDIA Coat Comp. A (Finishing) Long Rz : 8.784μm Neck Uncoated CBN Small Wear Chipping PCD 7 Holes Milled Work Material : STAVAX(52HRC) Tool : BNBR 2D200R050-0604(ø2×r 0.5) Rz : 13.88μm MOLD FINISH MASTER Comp. B Cutting Conditions : n=20,000min-1, vf=800mm/min ap=0.03mm, pf=0.70mm Oil Mist Coated Carbide Cutting Conditions : n=4,800min-1, vf=120mm/min 7 Holes Milled ap=0.03mm, pf=0.70mm Oil Mist I18

Каталог Sumitomo инструмент для отрезки

Каталог Sumitomo инструмент для отрезки Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Каталог Sumitomo сплавы и режимы

Каталог Sumitomo сплавы и режимы Каталог Sumitomo специальные торцевые фрезы

Каталог Sumitomo специальные торцевые фрезы Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами