Каталог Sumitomo монолитные фрезы - страница 111

Навигация

- I_001

- I_1-001

- I_1-002

- I_1-003

- I_1-004

- I_1-005

- I_1-006

- I_002

- I_003

- I_004

- I_005

- I_006

- I_007

- I_008

- I_009

- I_010

- I_011

- I_012

- I_013

- I_014

- I_015

- I_016

- I_017

- I_018

- I_019

- I_020

- I_021

- I_022

- I_023

- I_024

- I_025

- I_026

- I_027

- I_028

- I_029

- I_030

- I_031

- I_032

- I_033

- I_034

- I_035

- I_036

- I_037

- I_038

- I_039

- I_040

- I_041

- I_042

- I_043

- I_044

- I_045

- I_046

- I_047

- I_048

- I_049

- I_050

- I_051

- I_052

- I_053

- I_054

- I_055

- I_056

- I_057

- I_058

- I_059

- I_060

- I_061

- I_062

- I_063

- I_064

- I_065

- I_066

- I_067

- I_068

- I_069

- I_070

- I_071

- I_072

- I_073

- I_074

- I_075

- I_076

- I_077

- I_078

- I_079

- I_080

- I_081

- I_082

- I_083

- I_084

- I_085

- I_086

- I_087

- I_088

- I_089

- I_090

- I_091

- I_092

- I_093

- I_094

- I_095

- I_096

- I_097

- I_098

- I_099

- I_100

- I_101

- I_102

- I_103

- I_104

- I_105

- I_106

- I_107

- I_108

- I_109

- I_110

- I_111

- I_112

- I_113

- I_114

- I_115

- I_116

- I_117

- I_118

- I_119

- I_120

- I_121

- I_122

- I_123

- I_124

- I_125

- I_126

- I_127

- I_128

- I_129

- I_130

- I_131

- I_132

- I_133

- I_134

- I_135

- I_136

- I_137

- I_138

- I_139

- I_140

- I_141

- I_142

- I_143

- I_144

- I_145

- I_146

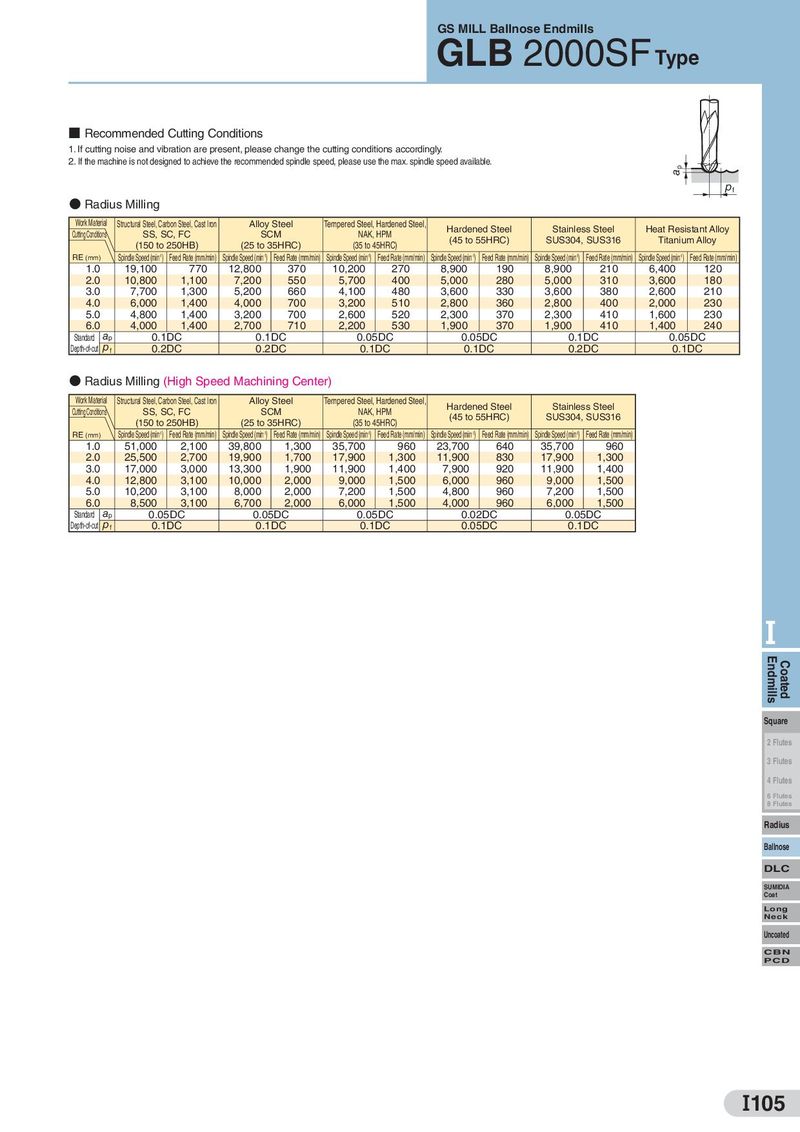

GS MILL Ballnose Endmills GLB 2000SF Type ■ Recommended Cutting Conditions 1. If cutting noise and vibration are present, please change the cutting conditions accordingly. 2. If the machine is not designed to achieve the recommended spindle speed, please use the max. spindle speed available. ap pf ● Radius Milling Work Material Structural Steel, Carbon Steel, Cast Iron Alloy Steel Tempered Steel, Hardened Steel, Hardened Steel Stainless Steel Heat Resistant Alloy Cutting Conditions SS, SC, FC SCM NAK, HPM (45 to 55HRC) SUS304, SUS316 Titanium Alloy (150 to 250HB) (25 to 35HRC) (35 to 45HRC) RE (mm) Spindle Speed (min-1) Feed Rate (mm/min) Spindle Speed (min-1) Feed Rate (mm/min) Spindle Speed (min-1) Feed Rate (mm/min) Spindle Speed (min-1) Feed Rate (mm/min) Spindle Speed (min-1) Feed Rate (mm/min) Spindle Speed (min-1) Feed Rate (mm/min) 1.0 19,100 770 12,800 370 10,200 270 8,900 190 8,900 210 6,400 120 2.0 10,800 1,100 7,200 550 5,700 400 5,000 280 5,000 310 3,600 180 3.0 7,700 1,300 5,200 660 4,100 480 3,600 330 3,600 380 2,600 210 4.0 6,000 1,400 4,000 700 3,200 510 2,800 360 2,800 400 2,000 230 5.0 4,800 1,400 3,200 700 2,600 520 2,300 370 2,300 410 1,600 230 6.0 4,000 1,400 2,700 710 2,200 530 1,900 370 1,900 410 1,400 240 Standard ap 0.1DC 0.1DC 0.05DC 0.05DC 0.1DC 0.05DC Depth-of-cut pf 0.2DC 0.2DC 0.1DC 0.1DC 0.2DC 0.1DC ● Radius Milling (High Speed Machining Center) Work Material Structural Steel, Carbon Steel, Cast Iron Alloy Steel Tempered Steel, Hardened Steel, Hardened Steel Stainless Steel Cutting Conditions SS, SC, FC SCM NAK, HPM (45 to 55HRC) SUS304, SUS316 (150 to 250HB) (25 to 35HRC) (35 to 45HRC) RE (mm) Spindle Speed (min-1) Feed Rate (mm/min) Spindle Speed (min-1) Feed Rate (mm/min) Spindle Speed (min-1) Feed Rate (mm/min) Spindle Speed (min-1) Feed Rate (mm/min) Spindle Speed (min-1) Feed Rate (mm/min) 1.0 51,000 2,100 39,800 1,300 35,700 960 23,700 640 35,700 960 2.0 25,500 2,700 19,900 1,700 17,900 1,300 11,900 830 17,900 1,300 3.0 17,000 3,000 13,300 1,900 11,900 1,400 7,900 920 11,900 1,400 4.0 12,800 3,100 10,000 2,000 9,000 1,500 6,000 960 9,000 1,500 5.0 10,200 3,100 8,000 2,000 7,200 1,500 4,800 960 7,200 1,500 6.0 8,500 3,100 6,700 2,000 6,000 1,500 4,000 960 6,000 1,500 Standard ap 0.05DC 0.05DC 0.05DC 0.02DC 0.05DC Depth-of-cut pf 0.1DC 0.1DC 0.1DC 0.05DC 0.1DC I Endmills Coated Square 2 Flutes 3 Flutes 4 Flutes 6 Flutes 8 Flutes Radius Ballnose DLC SUMIDIA Coat Long Neck Uncoated CBN PCD I105

Каталог Sumitomo инструмент для отрезки

Каталог Sumitomo инструмент для отрезки Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Каталог Sumitomo сплавы и режимы

Каталог Sumitomo сплавы и режимы Каталог Sumitomo специальные торцевые фрезы

Каталог Sumitomo специальные торцевые фрезы Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами