Каталог Sumitomo монолитные фрезы - страница 19

Навигация

- I_001

- I_1-001

- I_1-002

- I_1-003

- I_1-004

- I_1-005

- I_1-006

- I_002

- I_003

- I_004

- I_005

- I_006

- I_007

- I_008

- I_009

- I_010

- I_011

- I_012

- I_013

- I_014

- I_015

- I_016

- I_017

- I_018

- I_019

- I_020

- I_021

- I_022

- I_023

- I_024

- I_025

- I_026

- I_027

- I_028

- I_029

- I_030

- I_031

- I_032

- I_033

- I_034

- I_035

- I_036

- I_037

- I_038

- I_039

- I_040

- I_041

- I_042

- I_043

- I_044

- I_045

- I_046

- I_047

- I_048

- I_049

- I_050

- I_051

- I_052

- I_053

- I_054

- I_055

- I_056

- I_057

- I_058

- I_059

- I_060

- I_061

- I_062

- I_063

- I_064

- I_065

- I_066

- I_067

- I_068

- I_069

- I_070

- I_071

- I_072

- I_073

- I_074

- I_075

- I_076

- I_077

- I_078

- I_079

- I_080

- I_081

- I_082

- I_083

- I_084

- I_085

- I_086

- I_087

- I_088

- I_089

- I_090

- I_091

- I_092

- I_093

- I_094

- I_095

- I_096

- I_097

- I_098

- I_099

- I_100

- I_101

- I_102

- I_103

- I_104

- I_105

- I_106

- I_107

- I_108

- I_109

- I_110

- I_111

- I_112

- I_113

- I_114

- I_115

- I_116

- I_117

- I_118

- I_119

- I_120

- I_121

- I_122

- I_123

- I_124

- I_125

- I_126

- I_127

- I_128

- I_129

- I_130

- I_131

- I_132

- I_133

- I_134

- I_135

- I_136

- I_137

- I_138

- I_139

- I_140

- I_141

- I_142

- I_143

- I_144

- I_145

- I_146

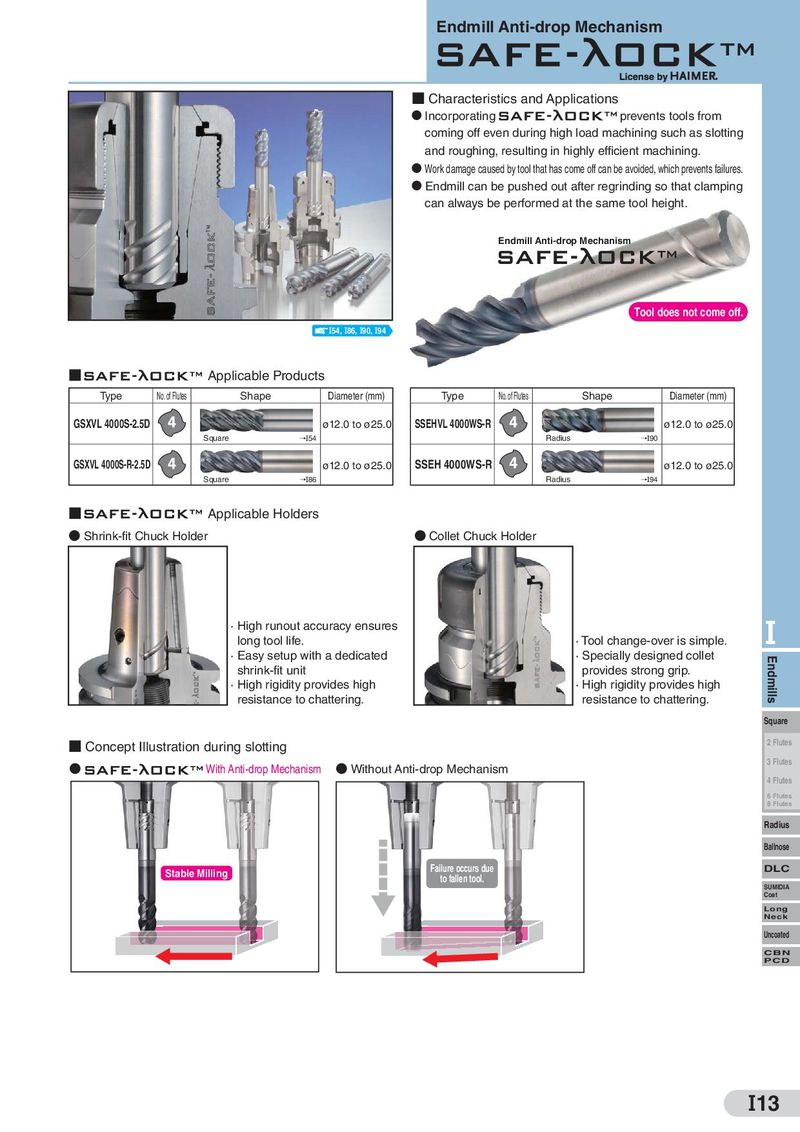

Endmill Anti-drop Mechanism ■ Characteristics and Applications D Incorporating prevents tools from coming off even during high load machining such as slotting and roughing, resulting in highly efficient machining. D Work damage caused by tool that has come off can be avoided, which prevents failures. D Endmill can be pushed out after regrinding so that clamping can always be performed at the same tool height. Endmill Anti-drop Mechanism Tool does not come off. I54, I86, I90, I94 ■ Applicable Products Type No. of Flutes Shape Diameter (mm) Type No. of Flutes Shape Diameter (mm) GSXVL 4000S-2.5D ø12.0 to ø25.0 SSEHVL 4000WS-R ø12.0 to ø25.0 Square →I54 Radius →I90 GSXVL 4000S-R-2.5D ø12.0 to ø25.0 SSEH 4000WS-R ø12.0 to ø25.0 Square →I86 Radius →I94 ■ Applicable Holders ● Shrink-fit Chuck Holder ● Collet Chuck Holder · High runout accuracy ensures I long tool life. · Tool change-over is simple. · Easy setup with a dedicated · Specially designed collet Endmills shrink-fit unit provides strong grip. · High rigidity provides high · High rigidity provides high resistance to chattering. resistance to chattering. Square ■ Concept Illustration during slotting 2 Flutes ● With Anti-drop Mechanism ● Without Anti-drop Mechanism 3 Flutes 4 Flutes 6 Flutes 8 Flutes Radius Ballnose Stable Milling Failure occurs due DLC to fallen tool. SUMIDIA Coat Long Neck Uncoated CBN PCD I13

Каталог Sumitomo инструмент для отрезки

Каталог Sumitomo инструмент для отрезки Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Каталог Sumitomo сплавы и режимы

Каталог Sumitomo сплавы и режимы Каталог Sumitomo специальные торцевые фрезы

Каталог Sumitomo специальные торцевые фрезы Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами