Каталог Sumitomo монолитные фрезы - страница 25

Навигация

- I_001

- I_1-001

- I_1-002

- I_1-003

- I_1-004

- I_1-005

- I_1-006

- I_002

- I_003

- I_004

- I_005

- I_006

- I_007

- I_008

- I_009

- I_010

- I_011

- I_012

- I_013

- I_014

- I_015

- I_016

- I_017

- I_018

- I_019

- I_020

- I_021

- I_022

- I_023

- I_024

- I_025

- I_026

- I_027

- I_028

- I_029

- I_030

- I_031

- I_032

- I_033

- I_034

- I_035

- I_036

- I_037

- I_038

- I_039

- I_040

- I_041

- I_042

- I_043

- I_044

- I_045

- I_046

- I_047

- I_048

- I_049

- I_050

- I_051

- I_052

- I_053

- I_054

- I_055

- I_056

- I_057

- I_058

- I_059

- I_060

- I_061

- I_062

- I_063

- I_064

- I_065

- I_066

- I_067

- I_068

- I_069

- I_070

- I_071

- I_072

- I_073

- I_074

- I_075

- I_076

- I_077

- I_078

- I_079

- I_080

- I_081

- I_082

- I_083

- I_084

- I_085

- I_086

- I_087

- I_088

- I_089

- I_090

- I_091

- I_092

- I_093

- I_094

- I_095

- I_096

- I_097

- I_098

- I_099

- I_100

- I_101

- I_102

- I_103

- I_104

- I_105

- I_106

- I_107

- I_108

- I_109

- I_110

- I_111

- I_112

- I_113

- I_114

- I_115

- I_116

- I_117

- I_118

- I_119

- I_120

- I_121

- I_122

- I_123

- I_124

- I_125

- I_126

- I_127

- I_128

- I_129

- I_130

- I_131

- I_132

- I_133

- I_134

- I_135

- I_136

- I_137

- I_138

- I_139

- I_140

- I_141

- I_142

- I_143

- I_144

- I_145

- I_146

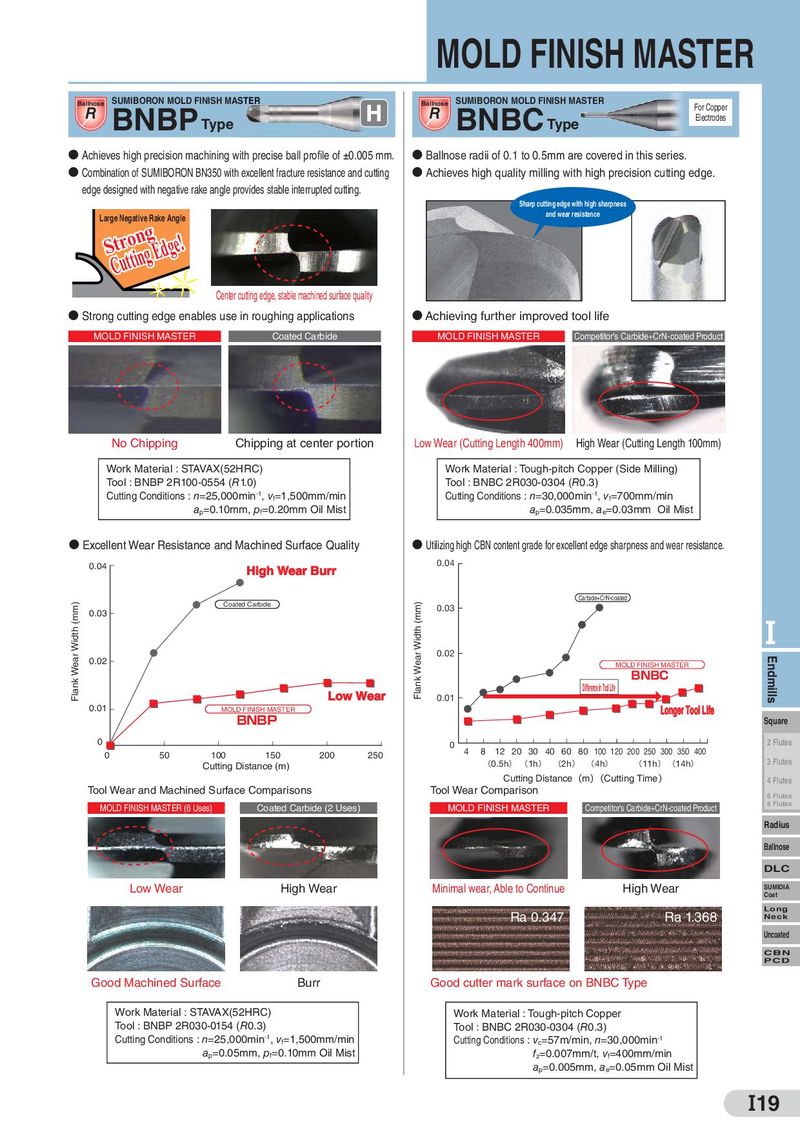

MOLD FINISH MASTER Ballnose SUMIBORON MOLD FINISH MASTER Ballnose SUMIBORON MOLD FINISH MASTER For Copper R BNBP Type R BNBC Type Electrodes D Achieves high precision machining with precise ball profile of ±0.005 mm. D Ballnose radii of 0.1 to 0.5mm are covered in this series. D Combination of SUMIBORON BN350 with excellent fracture resistance and cutting D Achieves high quality milling with high precision cutting edge. edge designed with negative rake angle provides stable interrupted cutting. Sharp cutting edge with high sharpness Large Negative Rake Angle and wear resistance SCtrutotinnggEdge! Center cutting edge, stable machined surface quality D Strong cutting edge enables use in roughing applications D Achieving further improved tool life MOLD FINISH MASTER Coated Carbide MOLD FINISH MASTER Competitor's Carbide+CrN-coated Product No Chipping Chipping at center portion Low Wear (Cutting Length 400mm) High Wear (Cutting Length 100mm) Work Material : STAVAX(52HRC) Work Material : Tough-pitch Copper (Side Milling) Tool : BNBP 2R100-0554 (R1.0) Tool : BNBC 2R030-0304 (R0.3) Cutting Conditions : n=25,000min-1, vf=1,500mm/min Cutting Conditions : n=30,000min-1, vf=700mm/min ap=0.10mm, pf=0.20mm Oil Mist ap=0.035mm, ae=0.03mm Oil Mist D Excellent Wear Resistance and Machined Surface Quality D Utilizing high CBN content grade for excellent edge sharpness and wear resistance. 0.04 High Wear Burr 0.04 Flank Wear Width (mm) Carbide+CrN-coated Flank Wear Width (mm) Coated Carbide 0.03 0.03 0.02 I 0.02 MOLD FINISH MASTER Endmills BNBC Low Wear Dif erence in Tool Life 0.01 0.01 MOLD FINISH MASTER Longer Tool Life BNBP Square 0 0 2 Flutes 0 50 100 150 200 250 4 8 12 20 30 40 60 80 100 120 200 250 300 350 400 Cutting Distance (m) 㸦0.5h㸧 㸦1h㸧 㸦2h㸧 㸦4h㸧 㸦11h㸧 㸦14h㸧 3 Flutes Cutting Distance(m)(Cutting Time) 4 Flutes Tool Wear and Machined Surface Comparisons Tool Wear Comparison 6 Flutes MOLD FINISH MASTER (6 Uses) Coated Carbide (2 Uses) MOLD FINISH MASTER Competitor's Carbide+CrN-coated Product 8 Flutes Radius Ballnose DLC Low Wear High Wear Minimal wear, Able to Continue High Wear SUMIDIA Coat Ra 0.347 Ra 1.368 Long Neck Uncoated CBN PCD Good Machined Surface Burr Good cutter mark surface on BNBC Type Work Material : STAVAX(52HRC) Work Material : Tough-pitch Copper Tool : BNBP 2R030-0154 (R0.3) Tool : BNBC 2R030-0304 (R0.3) Cutting Conditions : n=25,000min-1, vf=1,500mm/min Cutting Conditions : vc=57m/min, n=30,000min-1 ap=0.05mm, pf=0.10mm Oil Mist fz=0.007mm/t, vf=400mm/min ap=0.005mm, ae=0.05mm Oil Mist I19

Каталог Sumitomo инструмент для отрезки

Каталог Sumitomo инструмент для отрезки Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Каталог Sumitomo сплавы и режимы

Каталог Sumitomo сплавы и режимы Каталог Sumitomo специальные торцевые фрезы

Каталог Sumitomo специальные торцевые фрезы Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами