Общий каталог Palbit - страница 35

Навигация

- General Catalogue

- Index

- NEWS

- MILLING

- Milling tool selection

- Tools Overview

- Inserts Codification

- New grade PHS

- Inserts Overview

- Face Milling

- PLUS 28088

- PLUS 90260

- PLUS 90845

- PLUS 90945

- PLUS 91245

- LINEPRO 06045

- LINEPRO 09945

- LINEPRO 00036

- Hifeed Milling

- PENTA HIFEED 06320

- HIFEED 06410

- HIFEED 06690

- HIFEED 06815

- HIFEED 50560

- HIFEED 50060

- HIFEED 06590

- Shoulder Milling

- PLUS 49090

- PLUS 17190

- PLUS 17590

- PLUS 18190

- LINEPRO 20090

- LINEPRO 20190

- LINEPRO 20290

- TGPLUS 90090

- TGPLUS 90190

- TGPLUS 90390

- ALUPRO 76090

- ALUPRO 77090

- ALUPRO 08390

- LINEPRO 06290

- LINEPRO 17090

- LINEPRO 18090

- LINEPRO 15090

- Profile Milling

- PLUS 49095

- PLUS 45095

- TOROMILL 33590|33690|33790

- TOROMILL 33890|33990

- TOROMILL X2 35190

- TOROMILL 24590|25090|25190

- TOROMILL 25290|25390

- LINEPRO 40095|40595|41095

- Hardmill

- HARDMILL 72090

- Center & Chamfer

- Spot face

- End Mills Carbide

- Straight Flutes PCD

- Solide Carbide End Mills

- Selection Guide for Solid Carbide

- HF30G S/XL

- HB30G S/L

- HB30G L

- HF 45G S

- HC45FL

- HF30HL

- HB30HL

- HC35ML

- HC38AS

- Technical Data

- Troubleshooting

- Spare Parts

- Procedures for clamping screws

- Technical Data

- Milling Grades

- Comparative Grades Chart

- Formulas & calculations

- Troubleshooting

- DRILLING

- Drills Code Key

- Nomenclature

- Overview

- Jet Drills

- Integrex Drills

- Vortex Drills

- Trepanning Drills

- Solid Carbide Drills

- ISO Driling inserts code key

- Inserts

- Spare Parts

- Technical Data

- TURNING

- New turning grades

- ISO Turning Code key

- Negative Inserts Overview

- Positive Inserts Overview

- Negative Inserts

- CN Inserts

- CNMA

- CNMG-SF

- CNMG-LC

- CNMG-MS

- CNMG-MR

- CNMG-PM

- CNMG-ST

- CNMM-RP

- CNMM-HY

- CNMM-HZ

- DN Inserts

- DNMA

- DNMG-MF

- DNMG-SF

- DNMG-LC

- DNMG-MS

- DNMG-MR

- DNMG-PM

- DNMG-ST

- DNMG-MW

- DNMG-SS

- DNMG-HR

- DNMM-RP

- DNMX-02

- DNMX-03

- DNMX-01

- KN Inserts

- KNUX-01

- KNUX-02

- RN Inserts

- RNMA

- RNMG-ST

- SN Inserts

- SNMA

- SNMG-MF

- SNMG-SF

- SNMG-MR

- SNMG-PM

- SNMG-ST

- SNMG-SS

- SNMG-HR

- SNMM-RP

- SNMM-HY

- SNMM-HZ

- SNGN

- SNUN

- TN Inserts

- TNMA

- TNMG-MF

- TNMG-MS

- TNMG-MR

- TNMG-PM

- TNMG-ST

- TNMG-MW

- TNMG-SS

- TNMG-HR

- TNMX-01

- VN Inserts

- VNMA

- VNMG-MF

- VNMG-SF

- VNMG-LC

- VNMG-MS

- VNMG-MR

- VNMG-PM

- VNMG-ST

- VNMG-SS

- WN Inserts

- WNMA

- WNMG-MF

- WNMG-SF

- WNMG-LC

- WNMG-MS

- WNMG-PM

- WNMG-MR

- WNMG-ST

- WNMG-MW

- WNMG-SS

- WNMG-HR

- Positive Inserts

- CC Inserts

- CCMW

- CCMT-FP

- CCMT-BO

- CCMT-FM

- CCMT-FK

- CCMT-FW

- CCMT-LM

- CCMT-MP

- CCMT-MM

- CCMT-MK

- CCMT-MW

- CCGT-FS

- CCGT-LN

- DC Inserts

- DCMW

- DCMT-FP

- DCMT-FM

- DCMT-FK

- DCMT-FW

- DCMT-LM

- DCMT-MP

- DCMT-MM

- DCMT-MK

- DCMT-MW

- DCGT-FS

- DCGT-LN

- RC Inserts

- RCMT-CP

- RCMT-ST

- RCMT-RF

- RCMT-RM

- RCMX-ST

- RCMX-RM

- RCMX-RR

- RCGT-LN

- SC Inserts

- SCMW

- SCMT-FP

- SCMT-FM

- SCMT-FK

- SCMT-MP

- SCMT-MM

- SCMT-MK

- SCGT-LN

- SP Inserts

- SPUN

- SPMR-12

- SPMR-13

- TC Inserts

- TCMW

- TCMT-FP

- TCMT-FM

- TCMT-FK

- TCMT-FW

- TCMT-MP

- TCMT-MM

- TCMT-MK

- TCMT-MW

- TCGT-FS

- TCGT-LN

- TP Inserts

- TPUN

- TPMR-12

- TPMR-13

- VB Inserts

- VBMW

- VBMT-FP

- VBMT-FM

- VBMT-FK

- VBMT-MP

- VBMT-MM

- VBMT-MK

- VC Inserts

- VCMW

- VCMT-FP

- VCMT-FM

- VCMT-FK

- VCMT-MP

- VCMT-MM

- VCMT-MK

- VCGT-FS

- VCGT-LN

- PCD Inserts

- PCD Inserts selection

- ISO PCD Inserts code key

- Single Tip

- Negative Inserts

- CNGA Z1

- DNGA Z1

- SNGA Z1

- TNGA Z1

- VNGA Z1

- Positive Inserts

- OVERVIEW

- CCGT Z1

- CCGW Z1

- CPGT Z1

- CPGW Z1

- DCGT Z1

- DCGW Z1

- SCGT Z1

- SCGW Z1

- VCGT Z1

- VCGW Z1

- TCGT Z1

- TCGW Z1

- TPGT Z1

- TPGW Z1

- Full Edge - Positive Inserts

- CCGT FR/FL

- CCGW FR/FL

- TCGT FL

- TCGW FL

- PCD recommended cutting data

- Heavy machinning

- Bar Peeling

- Inserts code key

- Negative Inserts

- INGR-MP

- JNGF-MP

- LNGF-MP

- UNGF-MP

- TNMJ-MP

- TNGM-MP

- TNMM-LH

- XNMJ-MP

- XNMJ-MH

- XNGJ-RP

- WNGJ-MP

- RNMX-MP

- RNMX-RP

- RNMG-ST

- Railway Turning

- Inserts code key

- Negative Inserts

- CNMM-HY

- CNMM-HZ

- SNMM-HY

- SNMM-HZ

- LNUX-RMM

- LNUX-RRM

- LNUX-RHR

- LNUX-RMM-T

- LNUX-RRM-T

- LNUX-RHR-T

- Positive Inserts

- RCMR-RR

- RCMX-ST

- RCMX-RM

- RCMX-RR

- External Toolholders

- External toolholder code key

- Clamping System

- (C) Top Clamping Toolholders

- CKJN 93º

- CKNN 63º

- CSBP 75º

- CSDP 45º

- CSKP 75º

- CSSP 45º

- CSTP 60º

- CTBP 75º

- CTCP N 90º

- CTCP 90º

- CTDP 45º

- CTFP 90º

- CTGP 90º

- CTTP 60º

- (D) Dimple Lock Toolholders

- DCLN 95º

- DDJN 93º

- DSSN 45º

- DTGN 90º

- DWLN 95º

- (M) Wedge Clamp Toolholders

- MCLN 95º

- MSSN 45º

- MTEN 60º

- MTJN 93º

- MTNN 63º

- MWLN 95º

- (M-K) Double Lock Toolholders

- MCLN-K 95º

- MDJN-K 93º

- MSSN-K 45º

- MTJN-K 93º

- MVJN-K 93º

- MVQN-K 117º30’

- MVVN-K 72º30’

- MWLN-K 95º

- (P) Lever LockToolholders

- PCBN 75º

- PCFN 90º

- PCKN 75º

- PCLN 95º

- PCMN 50º

- PCSN 45º

- PDJN 93º

- PDNN 63º

- PRDC

- PRSC

- PRSN

- PSBN 75º

- PSDN 45º

- PSKN 75º

- PSSN 45º

- PTDN 45º

- PTFN 90º

- PTGN 90º

- PTTN 60º

- PWLN 95º

- (S) Center Screw Toolholders

- SCAC 90º

- SCLC 95º

- SDJC 93º

- SDNC 62º30’

- SRDC

- SSBC 75º

- SSDC 45º

- SSSC 45º

- STAC 90º

- STDC 45º

- STFC 90º

- STGC 90º

- STJC 93º

- STTC 60º

- SVHC 107º30’

- SVJB 93º

- SVJC 93º

- SVLC 95º

- SVVB 72º30’

- SVVC 72º30’

- SVXC 113º

- SVZC 100º

- Internal Toolholders

- Clamping System

- (C) Top Clamp Toolholders

- CKUN 93º

- CSKP 75º

- CTFP 90º

- CTUP 93º

- (D) Dimple Lock Toolholders

- DCLN 95º

- DDUN 93º

- (M) Wedge Clamp Toolholders

- MTUN 93º

- MWLN 95º

- (M-K) Double Lock Toolholders

- MCLN-K 95º

- MDUN-K 93º

- MSKN-K 75º

- MTFN 90º

- MTFN-K 90º

- MVUN-K 93º

- MWLN-K 95º

- (P) Lever Lock Toolholders

- PCKN 75º

- PCLN 95º

- A-PCLN 95º

- PDUN 93º

- A-PDUN 93º

- PDUN 93º-BT

- PSKN 75º

- A-PSKN 75º

- A-PSSN 45º

- PTFN 90º

- A-PTFN 90º

- PWLN 95º

- A-PWLN 95º

- (S) Center Screw Toolholders

- SCLC 95º

- A-SCLC 95º

- E-SCLC 95º

- SCLC N 95º

- SDQC 107º30’

- A-SDQC 107º30’

- SDUC 93º

- A-SDUC 93º

- E-SDUC 93º

- SDUC 93º-BT

- A-SDUC 93º-BT

- SSKC 75º

- A-SSSC 45º

- STFC 90º

- A-STFC 90º

- E-STFC 90º

- STUC 93º

- SVQC 107º30’

- A-SVQC 107º30’

- SVUB 93º

- SVUC 93º

- A-SVUC 93º

- A-SVJC 93º

- Anti-vibrations Toolholders

- BAV | toolholders

- (M) Wedge Clamp Toolholders

- MTUN 93º

- (P) Lever Lock Toolholders

- PCLN 95º

- PDUN 93º

- PWLN 95º

- (S) Center Screw Toolholders

- SCLC 95º

- SDUC 93º

- STFC 90º

- Internal Toolholders Set

- PK SCLC 95º

- PK SDQC 107º30’

- PK SDUC 93º

- PK STFC 90º

- Automatic Lathes

- Automatic Lathes code key

- Overview

- Center Screw System (S)

- SCAC 90º

- SCLC 95º

- SDAC 90º

- SDJC 93º

- SDNC 62º30’

- STJC 93º

- SVAC 90º

- SVJC 93º

- SVVC 72º30’

- Spare Parts

- CHIP BREAKERS

- CLAMPS (C HOLDERS)

- DIFFERENTIALS SCREWS

- LEVERS

- LEVER SCREWS

- LOCK PINS

- SCREWS (TORX)

- SHIMS (V SHAPES)

- SHIMS (W SHAPES)

- SHIMS (KNUX SHAPES)

- SPRINGS

- WEDGE CLAMPS (M HOLDERS)

- WEDGE CLAMPS (M-K HOLDERS)

- WRENCHES (ALLEN)

- WRENCHES (TORKS)

- Technical Data

- Turning Grades

- Comparative Grades Chart

- Comparative Chip-breaker Chart

- Chip-breaker Specifications

- Cutting Speed

- Selection Guide

- Troubleshooting

- Wiper Concept

- GROOVING & PARTING OFF

- Inserts Overview

- Grooving Plus

- Inserts code key

- GP Inserts

- Blades & Toolholders code key

- Blades & Toolholders

- GP Toolholders

- Grooving

- Inserts code key

- Inserts Overview

- Inserts GCMX

- Inserts SANCAR

- Blades code key

- Blades

- Toolholders

- Trigon inserts code key

- Flat grooving inserts

- Full radius grooving inserts

- External toolholder code key

- External toolholder

- Internal toolholder code key

- Internal toolholder

- SAL

- Inserts code key

- Toolholders code key

- Toolholders

- Inserts

- Technical data

- Spare Parts

- Technical Data

- THREADING

- THREAD MILLING

- Inserts code key

- Inserts program

- iso

- un unc, unf, unef, uns

- whit bsw, bsf, bsp

- bspt

- npt

- nptf

- nps

- npsf

- pg din 40430

- unj

- american buttress

- acme

- Tooholders code key

- Multi insert toolholders

- Internal toolholders

- External toolholders

- Single insert toolholders

- wssn-1

- wssn-1 | Long shank

- ecsn-1 | Long carbide shank

- Double insert toolholders

- wssn-2

- Toolholders technical data

- Technical Data

- THREAD TURNING

- Threading - Step by Step Example

- Inserts Overview

- Partial Profile inserts

- Partial Profile code key

- Partial Profile 60º

- Partial profile 55º

- Full Profile inserts

- full profile inserts code key

- ISO METRIC ISO 965-1: 1999-11 | DIN 13: 2005-08

- AMERICAN UN (UNC, UNF, UNEF) | ANSI B1.1-1982

- WITHWORTH FOR BSW, BSF, BSP, B.S.84: 1956, DIN 259, ISO 228-1:1994

- BSPT | B.S.21: 1985

- NPT | ANSI/ASME B 1.20.1-1983

- NPTF | ANSI B 1.20.3-1976

- ROUND (DIN 405) | DIN 405:1997

- ROUND (DIN 20400) | DIN 20400:1990

- TRAPEZ | DIN 103:1977 | ISO 2901:1993

- AMERICAN ACME | ANSI/ASME: 1.5-1988

- STUB ACME | ANSI/ASME: 1.8-1988

- UNJ | MIL-S-8879A

- UNJ | MIL-S-8879A

- MJ | ISO 5855-1:1989

- AMERICAN BUTTRESS | ANSI B1.9-1973

- METRIC BUTTRESS SAGENGEWINDE (DIN 513:1985) SAW THREAD

- API | API SPEC 7:2001 (0.040 | 0.038r | 0.050)

- API | buttress casing | api spec 5b:2008 | oil threads

- API Round Casing & Tubing | API SPEC 5B:2008

- EXTREME LINE CASING | API SPEC 5B:2008 - OIL THREADS

- PG | DIN 40430; 1971

- Tangencial profile inserts

- Tangencial profile code key

- TNMC (Tangencial Inserts)

- TPMC (Tangencial Inserts)

- External Toolholders

- External toolholders code key

- STCN 90º

- SXAN

- Internal Toolholders

- Internal toolholders code key

- STGN 90º

- SXFN

- STGP 90º

- Spare Parts

- Technical Data

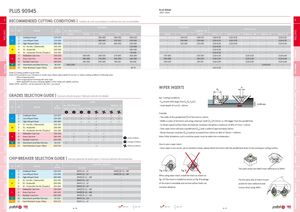

- GENERAL TECHNICAL DATA

MILLINGOverviewFace millingHifeed millingShoulder millingProfile millingHardmillCenter & ChamferSpot faceEnd MillsSpare partsTechnical Data MILLINGOverviewFace millingHifeed millingShoulder millingProfile millingHardmillCenter & ChamferSpot faceEnd MillsSpare partsTechnical Data PLUS 90945 PLUS 90945SNKX | SNHX A recommended cutting conditions | Condições de corte recomendadas | Condiciones de corte recomendables A Vc (m/min)ISOPSMMaterialHB(Brinell)Wear Resistance Vc (m/min) Feed fz (mm/t)Toughness PH0910 PH5705 PH7910 PH7920 PH7930 PH5740 PHS740 PH7740 SNHX 12… LP SNH(K)X 12… MP SNH(K)X 12… MK SNHX 12… LN SNHX 12… W 1 Unalloyed Steel 125-220 - - 190-280 180-250 160-220 - 140-170 140-170 0,10-0,35 0,10-0,35 - - 0,10-0,35 P 2 Low-Alloyed Steel 220-280 - - 180-240 170-210 150-180 - 130-160 130-160 0,10-0,35 0,10-0,35 - - 0,10-0,35 3 High-Alloyed Steel 280-380 - - 170-220 160-200 130-160 - 110-140 110-140 0,10-0,30 0,10-0,30 - - 0,10-0,30 4 SS - Ferritic / Martensitic 200-330 - - - - 120-180 - - - 0,10-0,30 - - - - M 5 SS - Austenitic 200-330 - - - - 100-160 - - - 0,10-0,30 - - - - 6 SS - Austenitic-ferritic (Duplex) 230-260 - - - - 70-140 - - - 0,10-0,25 - - - - 7 Malleable Cast Iron 130-230 - 190-340 180-320 170-300 160-280 170-300 - 130-250 0,10-0,35 - 0,10-0,35 - 0,10-0,40 K 8 Grey Cast Iron 180-245 - 180-300 170-280 150-250 140-240 150-260 - 110-220 0,10-0,35 - 0,10-0,35 - 0,10-0,40 9 Nodular Cast iron 160-250 - 140-250 100-240 90-210 90-200 130-220 - 80-170 0,10-0,30 - 0,10-0,30 - 0,10-0,40 N 10 Aluminium and Non Ferrous 30-130 350-1200 - - - - - - - - - - 0,10-0,35 - S 11 Heat Resistant Super Alloys 200-320 - - - - 30-75 - - - 0,07-0,20 - - - - (Note 1) Cutting conditions ae/Dc=70%. (Note 2) It’s possible to occur vibrations in certain cases. Please reduce depth of cut and / or reduce cutting conditions in following cases: - When using long shank; - When using long tool overhang with arbor type; - When application has poor clamping rigidity or when using a low rigidity machine. (Note 3) PH5… and PHS… can be used wet or dry. PH7… use only air. WIPER INSERTS Grades selection guide | Guia para selecção de graus | Tabla para selección de calidades Rec. Cutting Conditions: Grades - Fw at least 40% larger than fn (fn-f2xZ); ISO PSM Material HB Wear Resistance Toughness(Brinell)PH0910PH5705PH7910PH7920PH7930PH5740PHS740PH7740 - Axial deepth of cut 0,5 - 0,8mm. ~0,05 mm Example: 1 Unalloyed Steel 125-220 ✓ ✓ ✓ ✓ ✓P2Low-Alloyed Steel220-280✓✓✓✓✓ - The width of the parallel land (F) of the insert is 2,0mm. 3 High-Alloyed Steel 280-380 ✓ ✓ ✓ ✓ ✓ - Width a cutter of 10 inserts and using a feed per tooth (fz) of 0,3mm, i.e. 33% bigger than the parallel land. 4 SS - Ferritic / Martensitic 200-330 ✓ - To obtain a good surface finish, the feed per revolution should be a maximum of 80% of 2mm = 1,6mm. M 5 SS - Austenitic 200-330 ✓6SS - Austenitic-ferritic (Duplex)230-260✓ - Then wiper insert will have a parallel land (Fw) with a width of approximately 7,6mm. 7 Malleable Cast Iron 130-230 ✓ ✓ ✓ - Result: Feed per revolution (fn) could be increased from 1,6mm to 60% of 7,6mm = 4,56mm. K 8 Grey Cast Iron 180-245 ✓ ✓ ✓ Note: Other limitations, such a machine power, must be taken into consideration.Good Conditions 9 Nodular Cast iron 160-250 ✓ ✓ ✓ N 10 Aluminium and Non Ferrous 30-130 ✓S11Heat Resistant Super Alloys200-320 ✓ Average Conditions How to use a wiper insert:Difficult Conditions - Since wiper is one corner use to standard cutters, please attach the insert with the parallel land down to the workspace cutting surface. CHIP-BREAKER selection guide | Guia para aplicações do quebra-aparas | Guía para aplicación del rompevirutas ISO PSM Material HB(Brinell) Chip-Breaker Application1st choiseDificult Operations1Unalloyed Steel125-220SNHX 12… LPSNH(K)X 12… MP Fig. A Fig. B This point shows the SNKX insert difference to SNHX P 2 Low-Alloyed Steel 220-280 SNHX 12… LP SNH(K)X 12… MP3High-Alloyed Steel280-380SNH(K)X 12… MP- When using wiper insert, install the insert as shown on 4 SS - Ferritic / Martensitic 200-330 SNHX 12… LP - Fig. A if the insert is installed as shown on Fig. B breakage Put the same side of insert in each M 5 SS - Austenitic 200-330 SNHX 12… LP - of the insert is inevitable and normal surface finish can pocket for best radial and axial 6 SS - Austenitic-ferritic (Duplex) 230-260 SNHX 12… LP - not been obtained. runout when using SNKX. 7 Malleable Cast Iron 130-230 SNH(K)X 12… MK - K 8 Grey Cast Iron 180-245 SNH(K)X 12… MK - 9 Nodular Cast iron 160-250 SNH(K)X 12… MK - N 10 Aluminium and Non Ferrous 30-130 SNHX 12… LN - S 11 Heat Resistant Super Alloys 200-320 SNHX 12… LP - page A-236 page A -244 page A-236 page A -244 A - 66 A - 67

Общий каталог Palbit 2022

Общий каталог Palbit 2022