Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron - страница 9

Навигация

- L001

- L002

- L003

- L004

- L005

- L006

- L007

- L008

- L009

- L010

- L011

- L012

- L013

- L014

- L015

- L016

- L017

- L018

- L019

- L020

- L021

- L022

- L023

- L024

- L025

- L026

- L027

- L028

- L029

- L030

- L031

- L032

- L033

- L034

- L035

- L036

- L037

- L038

- L039

- L040

- L041

- L042

- L043

- L044

- L045

- L046

- L047

- L048

- L049

- L050

- L051

- L052

- L053

- L054

- L055

- L056

- L057

- L058

- L059

- L060

- L061

- L062

- L063

- L064

- L065

- L066

- L067

- L068

- L069

- L070

- L071

- L072

- L073

- L074

- L075

- L076

- L077

- L078

- L079

- L080

- L081

- L082

- L083

- L084

- L085

- L086

- L087

- L088

- L089

- L090

- L091

- L092

- L093

- L094

- L095

- L096

- L097

- L098

- L099

- L100

- L101

- L102

- L103

- L104

- L105

- L106

- L107

- L108

- L109

- L110

- L111

- L112

- L113

- L114

- L115

- L116

- L117

- L118

- L119

- L120

- L121

- L122

- L123

- L124

- L125

- L126

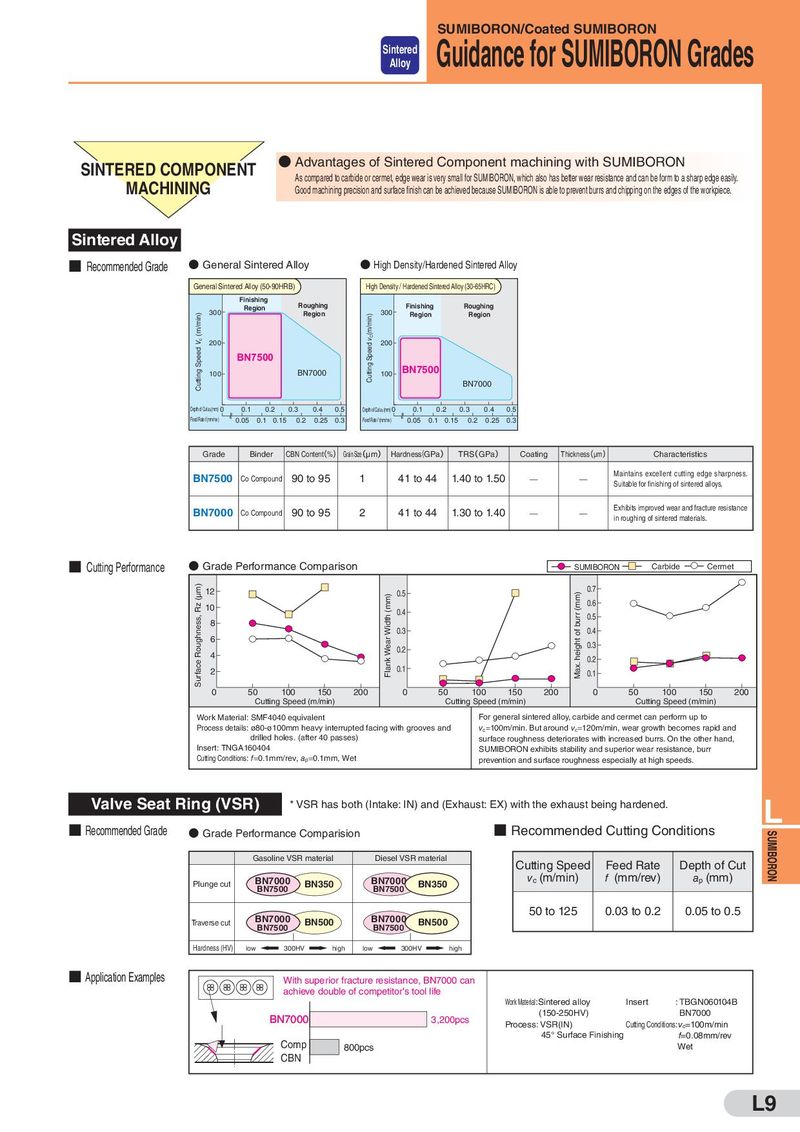

SUMIBORON/Coated SUMIBORON Sintered Guidance for SUMIBORON Grades Alloy SINTERED COMPONENT ● Advantages of Sintered Component machining with SUMIBORON MACHINING As compared to carbide or cermet, edge wear is very small for SUMIBORON, which also has better wear resistance and can be form to a sharp edge easily. Good machining precision and surface finish can be achieved because SUMIBORON is able to prevent burrs and chipping on the edges of the workpiece. Sintered Alloy ■ Recommended Grade ● General Sintered Alloy ● High Density/Hardened Sintered Alloy General Sintered Alloy (50-90HRB) High Density / Hardened Sintered Alloy (30-65HRC) Finishing Roughing Finishing Roughing 300 Region Region 300 Region Region Cutting Speed Vc (m/min) 200 Cutting Speed vC(m/min) 200 BN7500 100 BN7000 100 BN7500 BN7000 DepthofCutap(mm) 0 0.1 0.2 0.3 0.4 0.5 DepthofCutap(mm) 0 0.1 0.2 0.3 0.4 0.5 Feed Rate f (mm/rev) 0.05 0.1 0.15 0.2 0.25 0.3 Feed Rate f (mm/rev) 0.05 0.1 0.15 0.2 0.25 0.3 Grade Binder CBN Conten(t %) Grain Siz(e μm) Hardness(GPa) TRS(GPa) Coating Thickness(μm) Characteristics BN7500 Co Compound 90 to 95 1 41 to 44 1.40 to 1.50 ̶ ̶ Maintains excellent cutting edge sharpness. Suitable for finishing of sintered alloys. BN7000 Co Compound 90 to 95 2 41 to 44 1.30 to 1.40 ̶ ̶ Exhibits improved wear and fracture resistance in roughing of sintered materials. ■ Cutting Performance ● Grade Performance Comparison D SUMIBORON ■ Carbide D Cermet Surface Roughness, Rz (μm) ■ 0.7 D 12 ■ Flank Wear Width (mm) 0.5 ■ Max. height of burr (mm) 10 0.6 D D ■ 0.4 0.5 D 8 D D 0.3 0.4 6 D D D 0.3 0.2 D 4 D DD D D 0.2 ■ D■ D 0.1 D D ■D 2 D D 0.1 ■D ■D 0 50 100 150 200 0 50 100 150 200 0 50 100 150 200 Cutting Speed (m/min) Cutting Speed (m/min) Cutting Speed (m/min) Work Material: SMF4040 equivalent For general sintered alloy, carbide and cermet can perform up to Process details: ø80-ø100mm heavy interrupted facing with grooves and vc=100m/min. But around vc=120m/min, wear growth becomes rapid and drilled holes. (after 40 passes) surface roughness deteriorates with increased burrs. On the other hand, Insert: TNGA160404 SUMIBORON exhibits stability and superior wear resistance, burr Cutting Conditions: f=0.1mm/rev, ap=0.1mm, Wet prevention and surface roughness especially at high speeds. Valve Seat Ring (VSR) * VSR has both (Intake: IN) and (Exhaust: EX) with the exhaust being hardened. L ■ Recommended Grade ● Grade Performance Comparision ■ Recommended Cutting Conditions SUMIBORON Gasoline VSR material Diesel VSR material Cutting Speed Feed Rate Depth of Cut Plunge cut BN7000 BN350 BN7000 BN350 vc (m/min) f (mm/rev) ap (mm) BN7500 BN7500 BN7000 BN7000 50 to 125 0.03 to 0.2 0.05 to 0.5 Traverse cut BN7500 BN500 BN7500 BN500 Hardness (HV) low 300HV high low 300HV high ■ Application Examples With superior fracture resistance, BN7000 can achieve double of competitor's tool life Work Material:Sintered alloy Insert : TBGN060104B BN7000 3,200pcs (150-250HV) BN7000 Process: VSR(IN) Cutting Conditions:vc=100m/min 45° Surface Finishing f=0.08mm/rev Comp 800pcs Wet CBN L9

Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo инструмент для отрезки

Каталог Sumitomo инструмент для отрезки Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal